Contact Us

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

In the evolving landscape of fluid transportation, selecting the right equipment is crucial for optimizing efficiency and performance. One of the most widely used options is the vertical turbine pump, which is favored for its ability to handle large volumes of water effectively. According to industry expert Dr. Michael Greenfield, a noted authority on pump technology, "The choice of the right vertical turbine pump can dramatically influence both the operational costs and efficiency of water management systems."

As we look towards 2025, understanding the key considerations in selecting a vertical turbine pump is more important than ever. With advancements in technology and increased demand for sustainable solutions, choosing the appropriate pump can appear daunting. This guide aims to break down the critical factors to consider, ensuring operators can make informed decisions that align with their specific needs, whether for irrigation, industrial applications, or municipal services. By focusing on efficiency, capacity, and materials, users can navigate the complexities of this essential machinery with confidence.

Understanding Vertical Turbine Pumps: Types and Applications

Vertical turbine pumps are a crucial solution for various applications, primarily in agricultural, industrial, and municipal water systems. These pumps are designed for deep well applications, effectively lifting water from underground to surface reservoirs. According to market research, the global vertical turbine pump market is expected to grow significantly, with projections indicating an increase in demand of approximately 6% annually between 2023 and 2028.

When selecting a vertical turbine pump, it is essential to consider the type and specifications based on your specific needs. Different types include dry-pit and wet-pit vertical turbine pumps, each catering to distinct environments. Dry-pit pumps are typically used in wastewater applications, while wet-pit versions are preferred for irrigation and industrial uses. Understanding your system's operational characteristics, such as flow rate and head requirements, is critical for optimal performance.

Tips: Always evaluate the efficiency rating of the pump, as high-efficiency models can reduce operational costs significantly over time. Additionally, ensure that the materials used in the pump construction are compatible with the fluids being handled to avoid corrosion and extend the life of the equipment. Proper installation and maintenance practices will also enhance the pump's overall performance and reliability.

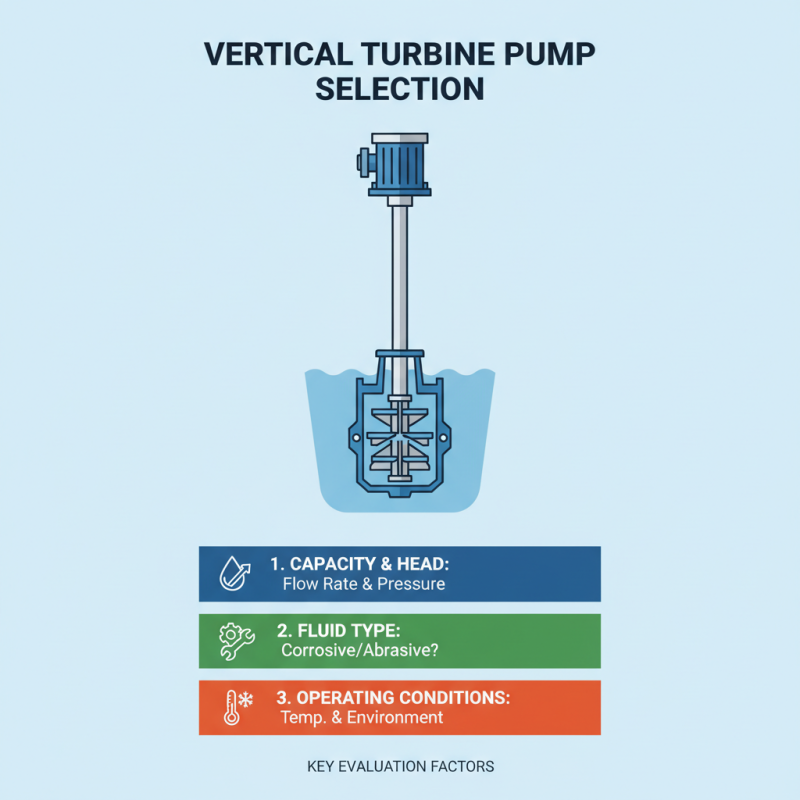

Key Factors to Consider When Selecting a Vertical Turbine Pump

When selecting a vertical turbine pump, several key factors must be carefully evaluated to ensure the system meets your specific needs. First and foremost, consider the pump's capacity and head requirements. This involves understanding the volume of fluid you need to move and the height it must be lifted. Accurate calculations of flow rate and pressure will help you choose a pump that can handle these demands effectively.

Another critical factor is the pump material and construction. Depending on the fluid being pumped—whether it’s clean water, corrosive chemicals, or slurries—the materials used in the pump's design must be compatible to prevent premature wear and tear. Assessing the environmental conditions, such as temperature and potential exposure to harsh elements, will also guide your choice. Additionally, consider the pump's efficiency and energy consumption, as selecting a pump that operates efficiently can significantly impact operational costs and sustainability.

Performance Metrics: Flow Rate and Head in Vertical Turbine Pumps

When selecting a vertical turbine pump, understanding the performance metrics—particularly flow rate and head—is crucial for meeting specific operational needs. The flow rate, measured in gallons per minute (GPM) or liters per second (L/s), dictates how much fluid the pump can move within a designated timeframe. Industry benchmarks indicate that high-performance vertical turbine pumps commonly achieve flow rates ranging from 500 to 10,000 GPM, with some specialized models exceeding this upper limit. According to a recent report by the Hydraulic Institute, optimizing flow rate relative to application requirements can lead to a 15-30% increase in system efficiency.

Head, defined as the height a pump can raise the fluid, is equally important. It is measured in feet or meters and represents the potential energy imparted to the fluid. Typical vertical turbine pumps are designed to provide heads of 50 to over 600 feet, depending on configuration and motor power. The American Society of Mechanical Engineers (ASME) emphasizes that accurately matching head requirements to pump specifications is essential; inadequate head can result in cavitation, decreased efficiency, and potential damage to the pump. Assessing both flow rate and head is vital for ensuring that the chosen pump effectively meets the application's demands while maximizing operational reliability and efficiency.

Performance Metrics of Vertical Turbine Pumps

Material Selection: Corrosion Resistance and Durability for Pumps

When selecting a vertical turbine pump, one of the most critical factors to consider is the material used in its construction. Corrosion resistance and durability are paramount, especially when the pump will be exposed to harsh fluids or extreme environmental conditions. Common materials include stainless steel, bronze, and various plastic composites. Stainless steel, for instance, offers excellent strength and resistance to a wide range of corrosive substances, making it ideal for applications involving aggressive chemicals or high salinity.

Additionally, the choice of material should align with the operational conditions of the pump. For instance, if the pump is intended for use in highly abrasive environments, materials with enhanced wear resistance should be prioritized to prolong the pump's lifespan. On the other hand, for less aggressive applications, more cost-effective materials may suffice. Understanding the specific fluid characteristics, temperature ranges, and pressure levels helps in making informed decisions that ensure reliability and efficiency in pump performance over time.

Maintenance and Efficiency: Maximizing the Lifespan of Your Pump

When selecting a vertical turbine pump, understanding how to maintain it effectively is essential for maximizing its lifespan and ensuring optimal efficiency. Regular maintenance not only prevents untimely breakdowns but also enhances the pump's performance, allowing it to operate at peak efficiency for longer periods.

**Tip 1:** Schedule routine inspections to check for wear and tear. Focus on components like seals, bearings, and impellers, as replacing these parts before they fail can save you from costly repairs and downtime.

Proper lubrication is another critical aspect of maintenance. Ensuring that all moving parts are adequately lubricated helps in reducing friction and heat buildup, which can lead to premature failure.

**Tip 2:** Use the recommended lubricants for your specific pump model and keep an eye on lubrication levels. Analyzing the lubricant for contaminants can provide insights into potential issues before they escalate.

Lastly, monitor the operating parameters of your pump closely. Variations in flow rate, pressure, and temperature can indicate underlying problems that may require immediate attention.

**Tip 3:** Implement a monitoring system that tracks these parameters to catch anomalies early, allowing for timely intervention and extended pump life.

Related Posts

-

What is a High Pressure Water Pump and How Does It Work

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications