Contact Us

2026 Best Condensate Tank Options for Efficient Water Management?

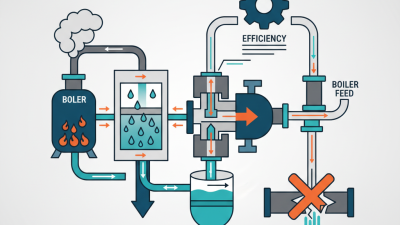

In recent years, efficient water management has become a critical concern across various industries. The condensate tank plays a pivotal role in this process. According to a report by the American Society of Mechanical Engineers, properly maintained condensate tanks can improve system efficiency by up to 30%. Industry expert John Reynolds emphasizes, "A well-designed condensate tank is essential for maximizing resource recovery.”

Many organizations overlook the importance of this equipment. They're unsure about the best options available. In 2023, nearly 40% of companies reported issues related to condensate management, leading to increased operational costs. Streamlining condensate handling is not just optimal; it is necessary. The right condensate tank can prevent waste and enhance overall efficiency.

Choosing the best condensate tank is not simple. Buyers need to consider factors like size, material, and application. Neglecting these aspects can lead to system failures. Companies must rethink their current practices. Investing in high-quality condensate tanks could yield significant long-term benefits.

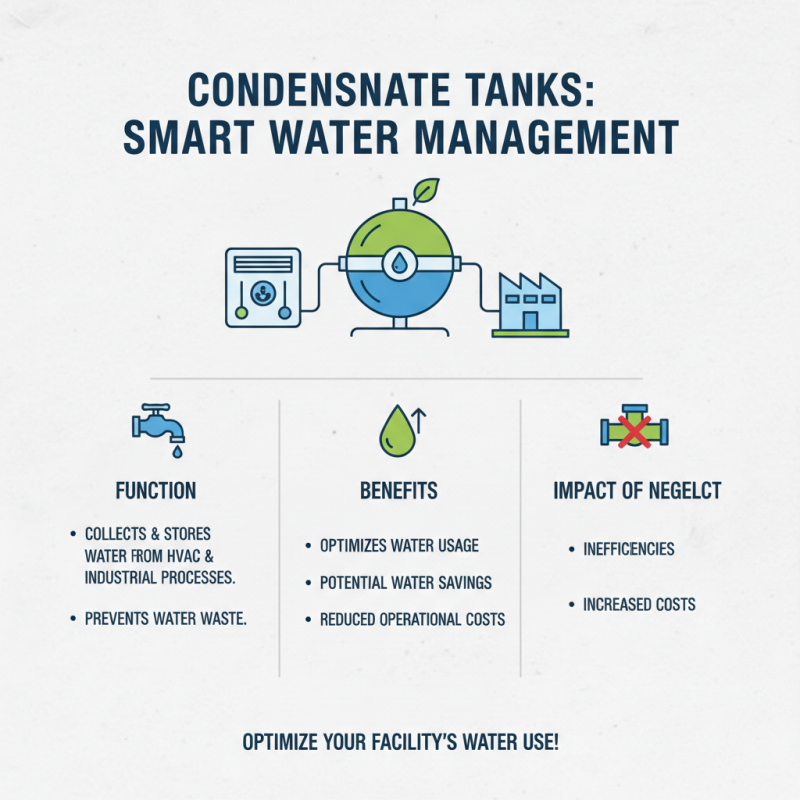

Overview of Condensate Tanks and Their Importance in Water Management

Condensate tanks play a crucial role in water management. They collect and store condensate water from HVAC systems or industrial processes. This prevents wastage and optimizes water usage in various applications. Efficient management of condensate leads to potential water savings. Many facilities overlook the importance of these systems. This can lead to inefficiencies and increased operational costs.

Proper design and maintenance of condensate tanks are vital. Tanks should be adequately sized for the specific needs of a facility. Regular inspections can prevent leaks and contamination. However, some operators may neglect this task, risking damage and loss. Over time, this oversight can result in higher energy and water expenses. In industrial settings, efficient condensate management also enhances sustainability. The constant need for fresh water is a growing concern globally.

Many options exist for condensate tanks, including different materials and capacities. Selecting the right tank requires thoughtful consideration of various factors, including operational needs. A mismatched tank could lead to system failures. In the quest for efficiency, it’s critical to regularly evaluate existing systems. Continuous improvement in water management practices can yield significant benefits over time.

Key Features to Consider When Selecting a Condensate Tank

When selecting a condensate tank, consider its capacity. The size must match your system's needs. A tank that is too small can lead to overflow. On the other hand, an oversized tank wastes space and resources. Think through the specific requirements of your operation.

Next, take into account the material quality. Condensate tanks come in various materials. Each has its pros and cons. Stainless steel is durable and resistant to corrosion. Plastic tanks are lightweight but may not withstand high temperatures. Weigh your options carefully.

Look for features that enhance efficiency. A good condensate tank should have effective insulation to minimize heat loss. Overflow alarms can help prevent flooding. Some tanks offer level indicators, aiding in maintenance. However, many users overlook these aspects. Reflecting on these details can lead to better water management.

2026 Best Condensate Tank Options for Efficient Water Management

This chart illustrates the storage capacity and efficiency ratings of various condensate tank options for 2026. The data represents a selection of models that excel in water management.

Top 2026 Condensate Tank Models for Residential and Commercial Use

When it comes to efficient water management, condensate tanks are essential. In 2026, a variety of models cater to both residential and commercial needs. Homeowners often prefer smaller, streamlined tanks. They fit snugly in basements or utility rooms. Many focus on maximizing storage while minimizing floor space.

Commercial setups may require larger tanks. These models handle higher volumes of condensate. Some feature advanced sensors for automatic drainage. This helps prevent overflow issues, which can be a major concern. It's wise to consider energy efficiency as well. A well-chosen tank can reduce energy costs.

Yet, not every option is perfect for every scenario. Some users might find installation challenging. Others may feel overwhelmed by maintenance needs. It's crucial to evaluate space, usage, and budget carefully. Balancing these factors ensures an effective water management solution suitable for any setting.

Comparative Analysis of Cost and Efficiency Among Leading Brands

When evaluating condensate tanks, cost and efficiency are key factors. A recent industry report shows that optimized tank designs can reduce water wastage by up to 30%. In terms of upfront costs, average pricing varies widely, ranging from $1000 to $5000 depending on capacity and materials used. This variance can confuse users looking for the best deal. Sometimes, the cheapest option may not offer the best long-term efficiency.

Operational efficiency is another consideration. Data indicates that high-efficiency tanks can save users an average of 15% on energy costs. Meanwhile, poorly designed tanks can lead to excessive maintenance. The hidden costs associated with inefficiency may outweigh initial savings. Reports suggest that 25% of users experience issues due to subpar products.

Sizing and installation also play crucial roles. Proper sizing can ensure peak performance. Users often underestimate this. Many projects face delays due to incorrect specifications. Regular maintenance is essential too, yet many overlook this. A well-maintained tank will outlast others, proving initial investment worthwhile. Balancing upfront cost against these efficiency metrics is essential for making informed choices.

Maintenance Tips for Prolonging the Life of Your Condensate Tank

Maintaining a condensate tank effectively can significantly extend its lifespan. Regular checks are vital. Inspect for corrosion and leaks every six months. The National Board estimates that proper maintenance can increase equipment efficiency by 15%. This alone can save a facility substantial costs over time.

Cleaning the tank is essential. Remove sludge and debris that can accumulate. Failure to do so may lead to operational inefficiencies. A report by the American Society of Mechanical Engineers highlights that 20% of condensate systems are inefficient due to poor maintenance practices. Schedule cleaning at least once a year.

Temperature regulation is another critical factor. Tanks should maintain optimal temperatures to prevent condensation issues. Monitoring the insulation is key. If insulation wears down, it can lead to significant heat loss. Establish a check every three months. These steps create an effective strategy for longevity, but too often, they are overlooked.

Related Posts

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

What is a Steam Condensate Pump and How Does It Work?

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

What Are the Key Tips for Effective Condensate Return Tank Management?