Contact Us

2026 Top Impeller Pump Innovations and Technologies Insights?

The world of impeller pumps is evolving rapidly. Innovations in design and technology are shaping the future of fluid dynamics. As we approach 2026, recognizing these developments is essential for various industries.

Recent advancements focus on enhancing efficiency and performance. New materials are making impeller pumps more durable and reliable. Smart technology integration offers real-time monitoring and better control. These changes reflect a growing need for sustainable solutions.

However, some challenges remain. The transition to new technologies may involve high initial costs and complexity. Manufacturers must also ensure compatibility with existing systems. Reflecting on these aspects can help in making informed decisions. The future of impeller pumps looks promising, yet careful consideration is crucial.

Key Trends in Impeller Pump Design Innovations for 2026

The impeller pump industry is evolving rapidly. In 2026, we can expect to see significant advancements in design and technology. One major trend is the focus on energy efficiency. Manufacturers are working to create pumps that use less energy while maintaining high performance. Innovative materials will reduce weight and increase durability, helping to extend the lifespan of pumps.

Another trend is the integration of smart technology. Sensors and IoT capabilities are becoming more common in impeller pumps. These features allow for real-time monitoring and data collection. Companies can predict maintenance needs more accurately. This innovation leads to fewer breakdowns and improves overall reliability.

Tips: Consider the environmental impact of your pump choices. Energy-efficient models may offer long-term savings. Additionally, look for features that allow for easy maintenance. Simplified upkeep can significantly reduce downtime. Stay informed about the latest innovations to stay ahead. Embracing new technologies might be daunting, but it can bring substantial benefits.

2026 Top Impeller Pump Innovations and Technologies Insights

| Innovation/Technology | Description | Key Benefits | Market Trends |

|---|---|---|---|

| Smart Pump Technology | Integration of IoT for real-time monitoring and performance optimization. | Enhanced efficiency and predictive maintenance. | Growing demand for automation in fluid handling. |

| Energy-Efficient Designs | Innovations aimed at reducing energy consumption during operation. | Lower operational costs and reduced carbon footprint. | Emphasis on sustainability in manufacturing processes. |

| Advanced Materials | Use of corrosion-resistant and lightweight materials in pump design. | Increased durability and longer service life. | Rise in demand for pumps in harsh environments. |

| Modular Pump Systems | Pumps designed for easy upgrades and scalability. | Flexibility to adapt to changing operational needs. | Adoption of flexible manufacturing practices. |

| Noise Reduction Technologies | Innovations focusing on minimizing vibration and noise during operation. | Improved working conditions and compliance with regulatory standards. | Increasing regulations on industrial noise pollution. |

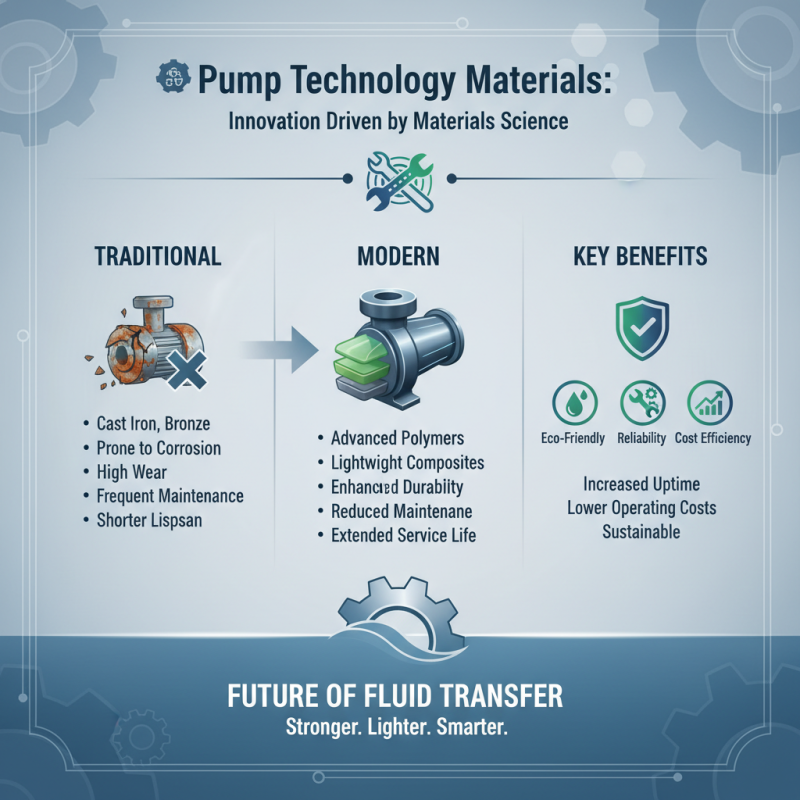

Advancements in Material Technology for Enhanced Pump Durability

Innovations in pump technology largely stem from advancements in material science. Today, we see a shift towards more robust materials that promise enhanced durability. Lightweight composites and advanced polymers are gaining traction. These materials resist corrosion and wear better than traditional options. This reduces maintenance needs and prolongs service life.

However, not every new material performs as expected. Some composites can be costly, and their long-term reliability still needs evaluation. Engineers are now tasked with balancing performance and price. Each new innovation brings hope, yet challenges remain. Testing these materials in real-world conditions is vital.

Moreover, environmental considerations are crucial. Sustainable materials are slowly emerging, but their performance under stress is a concern. Demand for greener solutions drives innovation, yet compromises may arise. The pursuit of enhanced pump durability must also consider ecological impacts. Future designs will need to harmonize these factors to succeed.

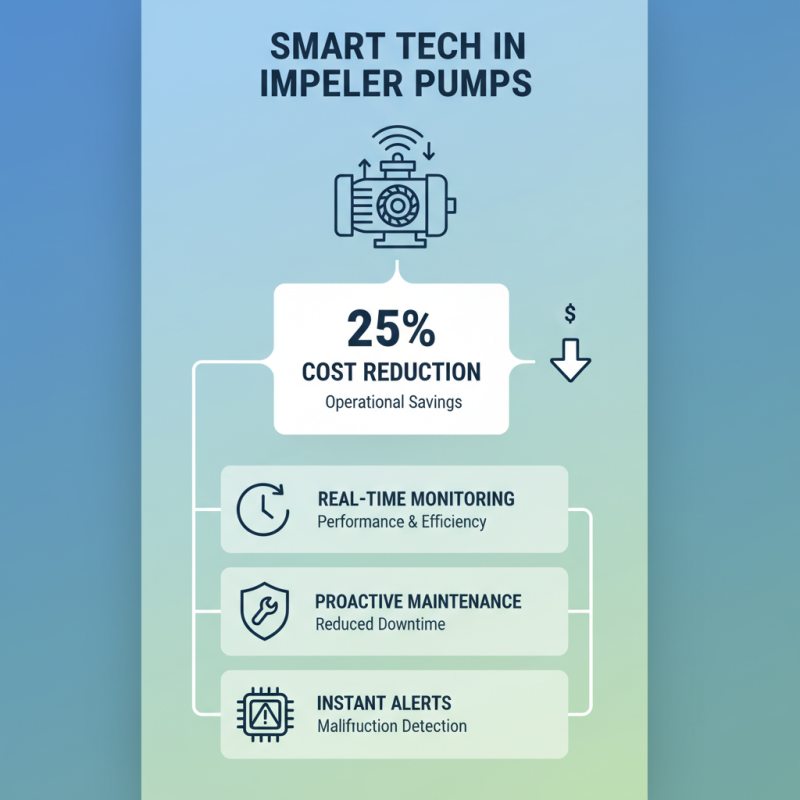

Integration of Smart Technology in Impeller Pump Operations

The integration of smart technology in impeller pump operations is transforming the industry. Data from recent reports indicate that adopting smart technologies can lead to a reduction in operational costs by up to 25%. This technology enables real-time monitoring of pump performance, which helps in proactive maintenance. With sensors installed, operators receive immediate alerts on potential malfunctions.

Moreover, the ability to collect and analyze data enhances efficiency. Advanced analytics can predict failure points, reducing downtime. However, companies must consider the challenges of data overload. Not all data is valuable. A focused approach is needed to extract actionable insights from the vast amounts of information collected.

While smart technology offers significant benefits, it is not a cure-all. The initial investment can be high. Training staff to navigate these new systems also presents a hurdle. The learning curve may slow down immediate productivity gains. Still, the long-term advantages suggest that embracing this shift is essential for growth and sustainability in the impeller pump sector.

Sustainability Practices Shaping the Future of Pump Manufacturing

The global pump manufacturing industry is undergoing significant transformation, driven by sustainability practices. In 2022, approximately 60% of pump manufacturers reported prioritizing eco-friendly materials. This shift is a response to growing environmental regulations and market demand for sustainable products. Companies are investigating biodegradable and recyclable materials for their pump components.

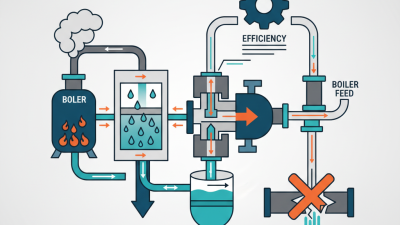

Innovation in energy efficiency is another key trend. Reports show that energy-efficient pumps can reduce operational costs by up to 20%. Many manufacturers are adopting advanced designs that minimize energy consumption. For instance, variable frequency drives (VFDs) are increasingly integrated into pumping systems. They provide precise control, enhancing overall system performance.

However, transitioning to sustainable practices does not come without challenges. One concern is the initial investment in new technologies. Some companies hesitate, fearing the financial implications. Moreover, sourcing sustainable materials can complicate supply chains. Thus, the path to sustainability is not straightforward. Ongoing education and collaboration within the industry will be crucial in overcoming these barriers.

Next-Generation Efficiency Improvements in Impeller Pump Performance

The impeller pump industry is experiencing significant innovation, especially in terms of efficiency. Next-generation designs focus on maximizing flow while minimizing energy consumption. Advanced materials contribute to lighter and more durable impellers. These changes lead to better performance in various applications.

A common challenge faced is balancing efficiency with cost. Many manufacturers strive to cut expenses, which can sometimes compromise quality. For instance, cheaper materials may not withstand harsh environments as well as premium options. Therefore, careful consideration is vital when selecting materials and designs to ensure long-lasting performance.

Moreover, the implementation of smart technology is reshaping the landscape. Monitoring systems track performance metrics in real-time. This data collection allows for immediate adjustments, optimizing efficiency. However, integrating such technology can be complicated. Training staff and managing data require resources that many small operators may struggle to provide. Ultimately, there’s a continuous quest for improvement in pump efficiency, with many paths to explore.

Related Posts

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

2025 How to Choose the Right Boiler Feed Tank for Your Needs

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications

-

The 5 Best Centrifugal Pumps for Efficient Fluid Transfer?

-

Top 10 Effective Ways to Optimize Boiler Water Quality for Better Performance

-

What is a Steam Condensate Pump and How Does It Work?