Contact Us

2026 Top Turbine Pump Innovations and Their Impact on Industries?

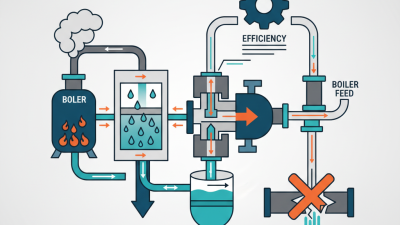

The 2026 innovations in turbine pump technology are set to reshape multiple industries. Recently, the global turbine pump market was valued at over $5 billion, with expectations to grow at a CAGR of 6.9% through 2028. This growth reflects rising demands in water management, oil, and gas sectors. Industry expert Dr. Emily Tran states, "Embracing new turbine pump designs significantly enhances efficiency and reduces operational costs."

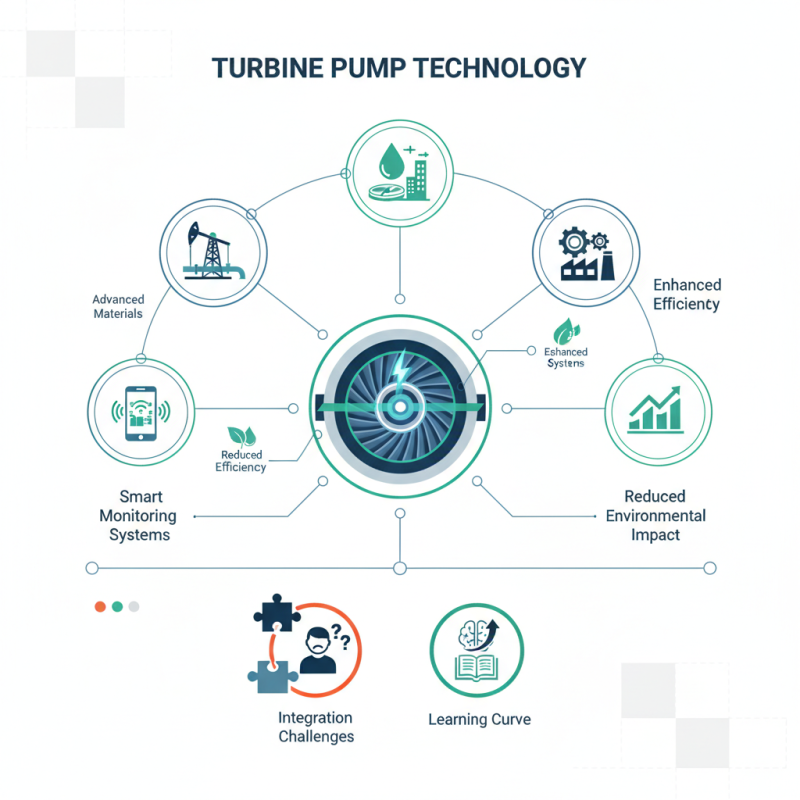

These innovations range from advanced materials to smart monitoring systems, which promise not only to improve performance but also to reduce environmental impact. Yet, challenges remain. Many companies struggle to integrate these new systems effectively. Additionally, the learning curve associated with modern turbine pump technologies can deter implementation. As innovation continues, companies must rethink their strategies to fully leverage these advancements in turbine pump technology.

Advancements in Turbine Pump Design for 2026

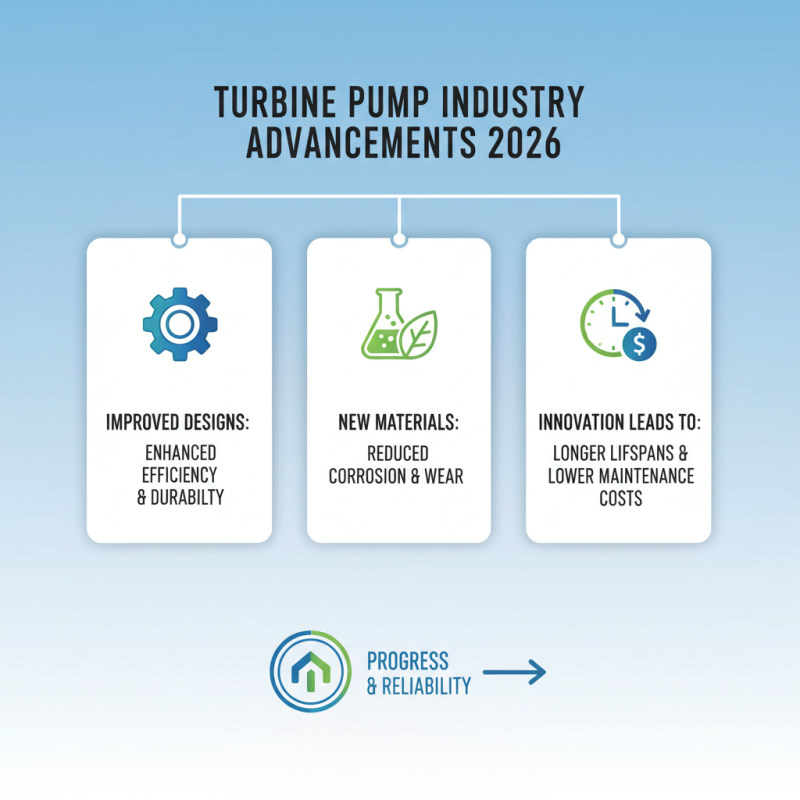

The turbine pump industry is witnessing remarkable advancements in 2026. Improved designs are aimed at enhancing efficiency and durability. New materials are being used to reduce corrosion and wear. This innovation leads to longer lifespans and lower maintenance costs.

Enhanced automation is also a key focus. Smart sensors are being integrated into pump systems. These sensors monitor performance in real-time. Operators receive alerts about issues before they escalate. However, this reliance on technology raises concerns. What if the system fails? Human oversight is still essential.

While innovations promise significant benefits, they also pose challenges. Not all designs will suit every application. Factors like environment and fluid types affect performance. The industry must adapt solutions for diverse needs. Balancing efficiency with practicality remains critical in this evolving landscape.

Key Technologies Driving Turbine Pump Efficiency

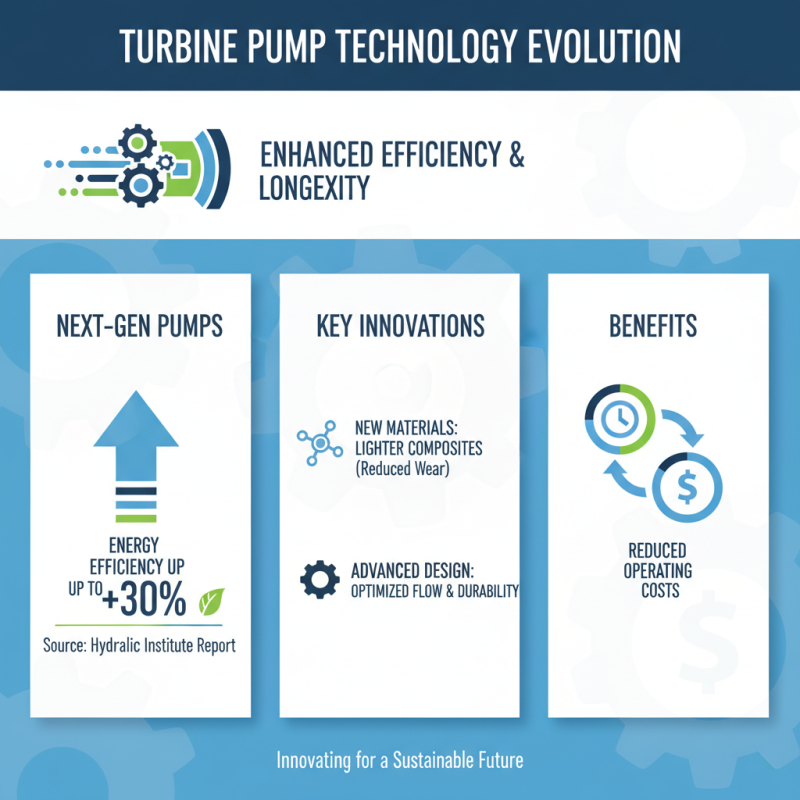

The landscape of turbine pump technology is rapidly evolving. Key innovations promise to enhance efficiency. According to a recent report by the Hydraulic Institute, next-generation turbine pumps are projected to improve energy efficiency by up to 30%. These advancements stem from new materials and design approaches. For instance, adopting lighter composite materials can reduce wear and tear, resulting in longer life spans for these pumps.

Integration of smart technologies is another driving force. Many pumps now include IoT sensors, enabling real-time monitoring. This data helps optimize performance but raises concerns about data security. Industry experts note that while remote diagnostics can improve maintenance, they also create potential vulnerabilities.

Moreover, improvements in pump hydraulics now allow for variable speed operation. Such features can lead to significant operational cost savings. A study indicated that variable speed drives could save up to 40% in energy costs for specific applications. As industries adopt these cutting-edge technologies, challenges will arise. Stakeholders must balance efficiency gains with the risks associated with new technologies.

Impact of Turbine Pump Innovations on Water Management

Turbine pump innovations are reshaping water management strategies across various industries. According to recent industry reports, advanced turbine pumps can improve efficiency by up to 30%. This efficiency translates to reduced energy consumption and lower operational costs. Enhanced designs allow for better handling of varying flow rates, which is crucial in managing water resources effectively.

However, the impact is not universally positive. While some regions see improved system resilience, others struggle with initial implementation costs. Access to these innovations may be limited in underserved areas. A study found that 40% of operators report challenges in adapting new technologies due to financial constraints. This reflects a significant gap between innovation availability and practical application.

Additionally, the environmental implications require careful consideration. Increased pump efficiency can lead to over-extraction of water in certain ecosystems. Balancing technological advancements with sustainable practices remains a complex challenge. The industry must address these disparities to ensure that turbine pump innovations benefit all sectors uniformly.

Applications of New Turbine Pumps in Energy Industries

In the energy sector, turbine pumps are crucial for efficiency and performance. Recent innovations have transformed their applications. New designs allow for handling various fluids at higher pressures. This development improves the pumping process in geothermal energy systems.

Next-generation turbine pumps feature enhanced materials. They resist erosion and corrosion better than previous models. This durability is essential for operations involving abrasive fluids. Many companies are exploring these pumps for offshore oil extraction. However, challenges remain with maintenance and operational costs.

The versatility of modern turbine pumps also supports renewable energy. They play a key role in biomass and hydropower systems. Innovative designs allow them to adapt to different energy sources. It's essential to evaluate both performance gains and potential drawbacks. Companies must carefully consider lifecycle impacts. The future of turbine pumps holds promise, but careful implementation is necessary.

2026 Top Turbine Pump Innovations and Their Impact on Industries

| Innovation | Key Features | Applications | Impact on Energy Industries |

|---|---|---|---|

| Smart Turbine Pumps | IoT Connectivity, Remote Monitoring | Oil & Gas, Renewable Energy | Enhances efficiency, reduces downtime |

| High-Efficiency Turbine Pumps | Optimized Blade Design, Improved Hydraulics | Power Generation, Water Supply | Significantly lowers energy consumption |

| Corrosion-Resistant Materials | Advanced Alloys, Composite Materials | Desalination, Chemical Processing | Increases lifespan, reduces maintenance costs |

| Variable Speed Turbine Pumps | Adjustable Speed Drives, Enhanced Control | Heating & Cooling Systems, Power Plants | Optimizes performance for changing demands |

| Green Turbine Pump Solutions | Eco-Friendly Materials, Energy Recovery | Geothermal, Solar Energy | Promotes sustainability, aligns with regulations |

Future Trends in Turbine Pump Development and Sustainability

As industries evolve, turbine pump technology must also adapt to new sustainability demands. Innovations in design and materials are leading the charge. For example, lightweight composites are replacing heavier metals. This change can reduce energy consumption. Furthermore, these materials often come from renewable sources, minimizing environmental impact.

Another significant trend is the integration of smart technology. Sensors in turbine pumps provide real-time data. This data allows operators to monitor performance and efficiency closely. However, implementing these technologies can be challenging. Training staff to adapt to new systems is essential for success.

Despite advancements, some challenges remain. Issues like maintenance and reliability persist. Users may still face high operational costs if not managed properly. There's a need for ongoing reflection on best practices in operations. Continuous learning will be crucial as the industry moves toward a more sustainable future.

2026 Innovations in Turbine Pump Technologies

This chart represents the anticipated percentage of adoption for key innovations in turbine pump technologies by 2026. Notable trends include a significant focus on efficiency improvements and sustainability features, reflecting the growing importance of environmental considerations and operational effectiveness in industrial applications.

Related Posts

-

Top 10 Turbine Pump Types for Efficient Water Management Systems

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

Understanding Canned Pumps: Types, Applications, and Benefits Explained

-

What is a Steam Condensate Pump and How Does It Work?