Contact Us

The 5 Best Centrifugal Pumps for Efficient Fluid Transfer?

Centrifugal pumps are essential in fluid transfer across various industries. They efficiently move liquids in applications ranging from manufacturing to wastewater management. According to a recent report by Grand View Research, the global centrifugal pump market was valued at USD 30.2 billion in 2022 and is expected to expand at a compound annual growth rate (CAGR) of 4.8% from 2023 to 2030.

Industry experts like Dr. Susan Harrington, a well-respected figure in the pump engineering sector, state, "The efficiency and reliability of centrifugal pumps make them the backbone of fluid handling systems." However, efficiency can sometimes be compromised. Factors such as pump design, sizing, and maintenance play critical roles in performance. Many users overlook these aspects, which can lead to underwhelming operational results.

Selecting the right centrifugal pump requires careful consideration. It’s not just about efficiency; it’s about matching the pump to specific needs. This may involve a trade-off between cost and performance. A well-informed choice can mean the difference between a reliable fluid transfer system and constant headaches. As technology advances, staying updated with the best options ensures optimal operation and cost-effectiveness.

Understanding Centrifugal Pumps: Basics and Applications

Centrifugal pumps are essential for fluid transfer in various industries. They use rotational energy to move fluids, creating a pressure difference. This design allows for efficient movement, making them popular in irrigation, water supply, and chemical processing applications. Understanding how these pumps work can help you choose the right one for your needs.

Tips for selecting a centrifugal pump include assessing your fluid's viscosity and density. High-viscosity fluids require pumps with specialized designs. Also, consider the pump's flow rate and head. A mismatch can lead to inefficiencies. Remember, sizing matters. An oversized pump may waste energy, while an undersized pump can lead to inadequate flow.

Maintenance is crucial for performance. Regularly check seals and bearings for wear. Neglecting these components can cause leaks and reduce efficiency. It's easy to overlook routine checks, but they are vital for long-term operation. If a pump is not working as expected, don't hesitate to reevaluate its setup. Sometimes, the simplest changes can enhance performance significantly.

The 5 Best Centrifugal Pumps for Efficient Fluid Transfer

This chart displays the flow rate (in gallons per minute) of five different types of centrifugal pumps to illustrate their efficiency in fluid transfer applications.

Key Features to Consider When Selecting a Centrifugal Pump

Choosing the right centrifugal pump is critical for efficient fluid transfer. Consider flow rate as a primary factor. Most industrial applications require pumps that can handle a specific volume efficiently. Typically, a pump should provide a flow rate between 10 to 1,000 GPM depending on the task. Keep an eye on the pump's efficiency rating. A more efficient pump can save significant energy and reduce operating costs.

Next, look at the pump's material components. Centrifugal pumps can be made from various materials such as stainless steel or ductile iron. The choice of material impacts durability and corrosion resistance. For example, pumps made of stainless steel can last longer in harsh environments. In fact, reports suggest that corrosion-resistant materials can increase pump life by up to 30%.

Don’t forget to consider the total dynamic head (TDH). It's a measure of the energy required to transport fluid. Many operators overlook this, leading to underperformance. It’s essential to match the pump's capabilities with your application’s needs. Performance curves provide valuable insights into how different pumps will behave under specific conditions. Using these curves helps avoid costly mistakes. Clarity in pump selection leads to better efficiency and reliability in operations.

Top 5 Centrifugal Pumps for Optimal Fluid Transfer Efficiency

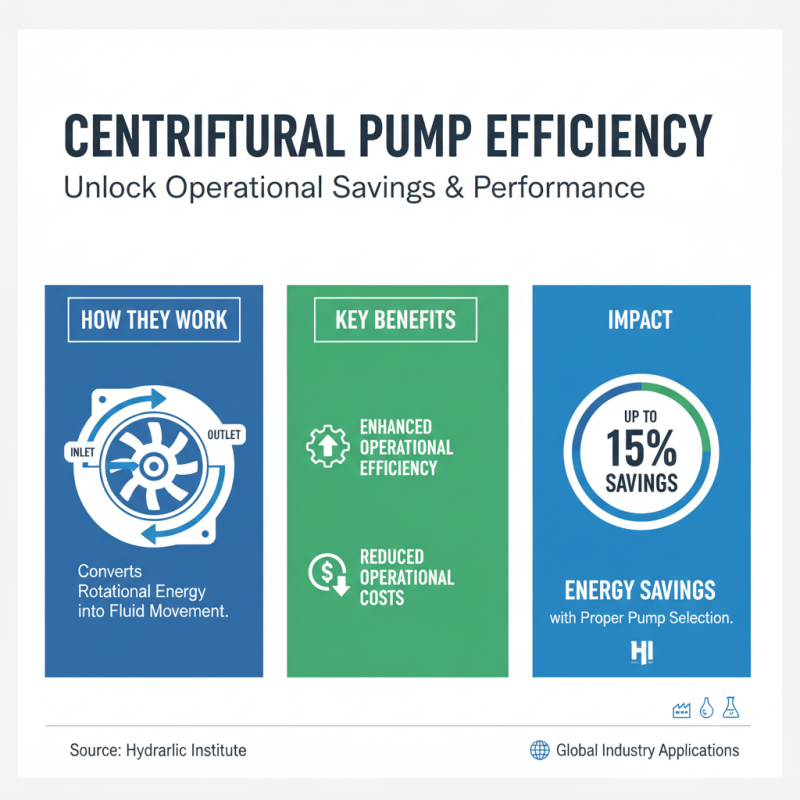

Centrifugal pumps excel at transferring fluids effectively across various industries. Their design focuses on converting rotational energy into fluid movement, which can enhance operational efficiency. According to the Hydraulic Institute, proper selection of centrifugal pumps can improve energy efficiency by around 15%. This reduction directly impacts operational costs.

Performance metrics often highlight that the best centrifugal pumps can operate within a broad range of flow rates. Systems with good pump design can reach efficiencies over 80%. However, suboptimal choices can lead to energy losses. For example, if a pump operates outside its best efficiency point, wear and tear can increase significantly. This necessitates careful analysis of application requirements and environmental conditions.

Long-term reliability is crucial, yet overlooked in some selections. Regular maintenance is key to sustaining operational efficiency. Reports suggest that up to 30% of centrifugal pumps underperform due to lack of upkeep. This highlights the importance of ongoing evaluation and adjusting to changes in fluid properties or system dynamics. Investing in a high-quality pump is essential, but recognizing the need for diligence post-installation remains a challenge for many.

Comparison of Performance Metrics for Leading Centrifugal Pumps

When evaluating centrifugal pumps, it's crucial to compare their performance metrics. Efficiency ratings are a significant factor for fluid transfer applications. According to a market analysis report, the best centrifugal pumps achieve efficiency levels above 80%. However, many pumps in use fall short of this benchmark. Understanding how to improve this efficiency is vital for users seeking cost-effective solutions.

Flow rate and head are two critical performance indicators. Ideal pumps must balance these metrics effectively. Reports indicate that the optimal flow rate for most industrial applications ranges from 100 to 500 gallons per minute. Yet, many users struggle to find pumps that maintain high performance across varying flow conditions. This inconsistency can lead to increased operational costs and downtime.

Another essential aspect is the specific speed, which impacts pump design and suitability. A study highlights that pumps with a specific speed between 5,000 and 11,000 RPM often perform best in medium to high head applications. However, selecting a pump based solely on these metrics may overlook important factors like maintenance requirements. Therefore, users should carefully consider how various performance metrics align with their unique operational needs.

Maintenance Best Practices for Enhanced Pump Longevity

Proper maintenance is crucial for ensuring the longevity of centrifugal pumps. Regular inspection is essential. Check for leaks and unusual noises. These signs might indicate underlying issues. A small leak can quickly escalate into a significant problem. Paying attention to these details is crucial for smooth operation.

Operating under the correct conditions is vital. Ensure the pump is suitable for the specific fluid being transferred. Using the wrong pump can lead to inefficiencies. Sometimes, it’s easy to overlook compatibility. This oversight can cause wear and tear on the pump components. Regular cleaning of the pump and its components helps prevent debris buildup.

Lubrication is often neglected but is critical for pump performance. Insufficient lubrication can lead to pump failure. Schedule routine checks of lubrication levels. Documenting maintenance practices is a good habit. It allows for better tracking of pump health over time. It’s not just about fixing issues; it’s about preventing them. Taking the time to reflect on maintenance strategies can lead to more efficient operations.

The 5 Best Centrifugal Pumps for Efficient Fluid Transfer

| Pump Model | Flow Rate (GPM) | Max Pressure (PSI) | Horsepower (HP) | Efficiency (%) |

|---|---|---|---|---|

| Model A | 100 | 150 | 5 | 85 |

| Model B | 150 | 120 | 7.5 | 90 |

| Model C | 200 | 100 | 10 | 88 |

| Model D | 120 | 180 | 5.5 | 82 |

| Model E | 80 | 220 | 4 | 78 |

Related Posts

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

Top 10 Small Centrifugal Pumps for Efficient Water Management in 2023

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

Top 10 High Temperature Pump Tips You Need to Know for Efficient Operation