Contact Us

What Are the Benefits of Magnetic Drive Pumps in 2026 Top Applications?

In 2026, the benefits of magnetic drive pumps become increasingly evident across various industries. These pumps are renowned for their ability to handle corrosive and hazardous fluids without leakage. According to a recent report by the Fluid Handling Association, the magnetic drive pump market is expected to grow by 15% annually, reflecting rising environmental concerns.

Dr. Emma Lawson, a noted expert in fluid dynamics, states, "Magnetic drive pumps are a game-changer for safety and sustainability in fluid transfer." This highlights the growing recognition of their role in promoting safer industrial practices. Many companies are adopting these pumps to comply with stringent regulations, ensuring product integrity while protecting the environment.

However, magnetic drive pumps are not without challenges. High initial costs can be a barrier for some businesses. Additionally, repair and maintenance can be complicated. Despite these issues, the long-term benefits outweigh the drawbacks, making magnetic drive pumps a vital component in modern applications.

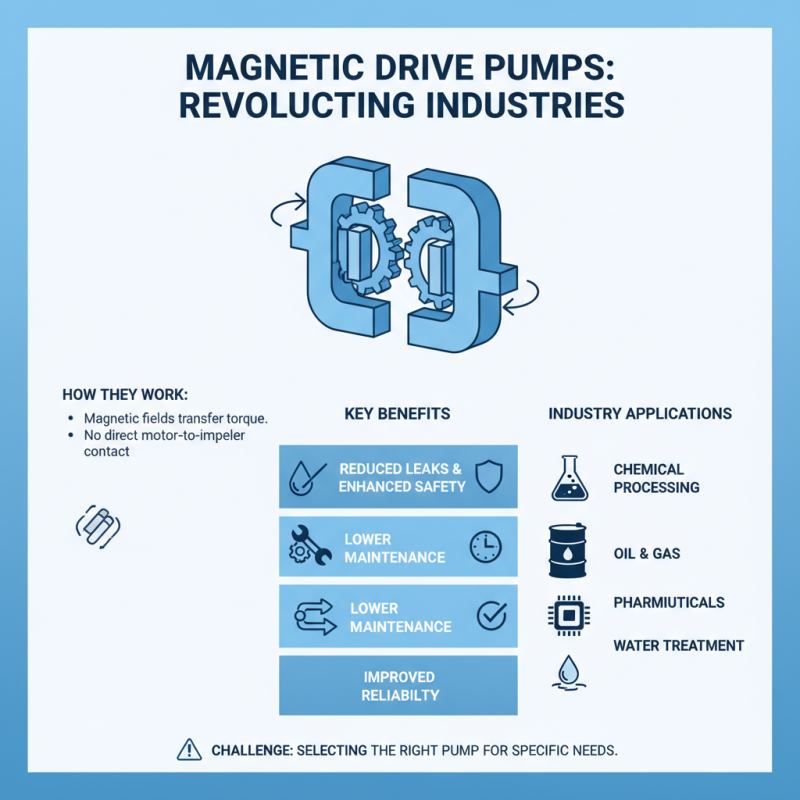

Overview of Magnetic Drive Pumps and Their Functionality

Magnetic drive pumps are revolutionizing various industries. They use magnetic fields to transfer torque from the motor to the impeller, eliminating direct contact. This design reduces the risk of leaks and enhances safety. Without traditional seals, the maintenance needs decrease significantly. However, there can be challenges in selecting the right pump for specific applications.

These pumps are highly effective in handling corrosive and volatile liquids. Their sealed design means less risk of contamination. Industries like chemicals, pharmaceuticals, and food processing greatly benefit from these features. Yet, they may not be ideal for all fluids. Understanding fluid characteristics is crucial to prevent inefficiencies. There are still complexities involved in installation and operation that should not be overlooked.

As technology advances, the potential for magnetic drive pumps continues to grow. They may lead to more sustainable practices in many fields. However, users must remain aware of the limitations and ensure proper application. Not every scenario may allow for optimal performance. Balancing benefits with potential drawbacks will require continuous assessment and adjustment.

Key Advantages of Magnetic Drive Pumps in Various Industries

Magnetic drive pumps are gaining traction in various industries, especially in 2026. Their ability to handle hazardous and corrosive fluids makes them valuable. According to a recent industry report, the use of magnetic drive pumps is expected to grow by 15% annually in the chemical processing sector.

These pumps feature a hermetic design, eliminating the risk of leaks. This is a significant benefit in environments where fluid spillage can lead to safety hazards. For instance, less than 2% of operations report leak issues when using these pumps. However, some users struggle with maintenance due to complex components, leading to operational downtime.

In pharmaceuticals, magnetic drive pumps are critical for maintaining purity standards. The pumps help avoid contamination. A study demonstrated that 70% of facilities using these pumps reported enhanced product integrity. Yet, their high initial costs can deter some companies. Investing in magnetic drive pumps might seem challenging for businesses with tight budgets, though the long-term savings are notable.

Top Applications for Magnetic Drive Pumps in 2026

Magnetic drive pumps have gained traction in various industries as we approach 2026. Their unique design eliminates the need for mechanical seals, reducing maintenance needs significantly. This attribute is particularly beneficial in chemical processing plants where leakage can lead to hazards. The ability to transport corrosive and volatile liquids safely makes them a preferred choice.

In addition, magnetic drive pumps are becoming vital in the pharmaceutical industry. Precise fluid control is crucial here. These pumps provide reliable performance while minimizing contamination risks. They're also being used increasingly in water treatment facilities. Their efficiency in transferring water without leaks can improve overall operational sustainability.

While these pumps have advantages, challenges exist. Not all liquids may be compatible with magnetic drive technology. Furthermore, initial costs can be higher than traditional pumps. Users should assess their specific needs closely. Balancing the benefits with potential drawbacks is key for optimal application.

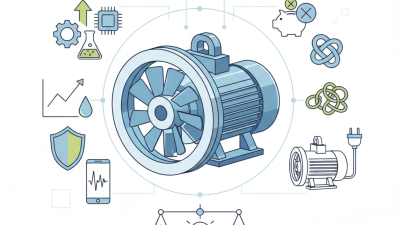

Technological Advancements Enhancing Magnetic Drive Pump Efficiency

In 2026, magnetic drive pumps are becoming increasingly efficient due to technological advancements. Enhanced designs allow for better fluid handling capabilities. These pumps minimize the risk of leaks by using a magnetic coupling. As a result, they are gaining traction in various industries, including chemicals and pharmaceuticals.

A noteworthy advancement is the use of advanced materials. These materials can withstand higher temperatures and corrosive substances. This makes pumps more durable over time. However, the cost of these materials can be high. Companies must weigh the benefits against their budgets.

Tips: Regular maintenance checks can prevent unexpected issues. Monitor performance metrics closely to detect changes early. Additionally, training staff on these pumps is crucial. Understanding how to operate them effectively can enhance their lifespan. It's necessary to reflect on any drawbacks of newer technologies. Sometimes, the latest innovations may not be the most suitable for every application.

What Are the Benefits of Magnetic Drive Pumps in 2026 Top Applications? - Technological Advancements Enhancing Magnetic Drive Pump Efficiency

| Application Area | Efficiency Improvement (%) | Key Benefits | Technological Advancements |

|---|---|---|---|

| Chemical Processing | 20 | Leak-free operation, Reduced maintenance | Advanced motor design, Enhanced seal technology |

| Water Treatment | 15 | Environmentally friendly, Consistent flow rates | Smart control systems, Energy-efficient designs |

| Food & Beverage | 18 | Hygienic handling, Increased safety | Sanitary design standards, Improved corrosion resistance |

| Pharmaceuticals | 22 | Precision dosing, Enhanced compliance | Automated monitoring, High-purity materials |

| Oil & Gas | 15 | Reduced risk of spills, Operational reliability | Improved heat resistance, Advanced magnetic coupling technology |

Environmental and Economic Impacts of Using Magnetic Drive Pumps

In recent years, magnetic drive pumps have gained attention for their environmental and economic benefits. By eliminating seals, these pumps reduce the risk of leaks. A study from the Fluid Handling Industry estimated that 34% of pump failures are due to seal issues. Fewer failures mean less downtime and maintenance, saving companies both time and resources. As industries push for sustainable practices, magnetic drive pumps align well with these goals.

Their efficiency also translates to lower energy consumption. According to the Energy Efficiency Council, using magnetic drive pumps can reduce energy use by up to 15%. This reduction is significant in settings where pumps run continuously. The upfront costs may be higher, but long-term savings can be substantial. Moreover, reduced energy usage leads to lower carbon footprints, benefiting the environment in the long run.

However, the transition to magnetic drive pumps is not without challenges. Initial installation can be complex, requiring careful planning and training. Additionally, not all applications are suitable for magnetic drive technology. Organizations might face resistance from employees used to traditional systems. Therefore, while the advantages are clear, some reflection is necessary on how to effectively implement these pumps for maximum benefit.

Benefits of Magnetic Drive Pumps in 2026 Top Applications

This chart illustrates the estimated reduction in environmental impact for key applications utilizing magnetic drive pumps in 2026. As shown, the food and beverage and pharmaceutical industries are projected to benefit the most, highlighting the importance of this technology in promoting sustainability across various sectors.

Related Posts

-

Top 10 Turbine Pump Types for Efficient Water Management Systems

-

What is a High Pressure Water Pump and How Does It Work

-

2026 Top Impeller Pump Innovations and Technologies Insights?

-

Top 10 Effective Ways to Optimize Boiler Water Quality for Better Performance

-

How to Choose the Right Liquid Propane Pump for Your Needs

-

The 5 Best Centrifugal Pumps for Efficient Fluid Transfer?