Contact Us

How to Choose the Best Ball Screw for Sale in 2026?

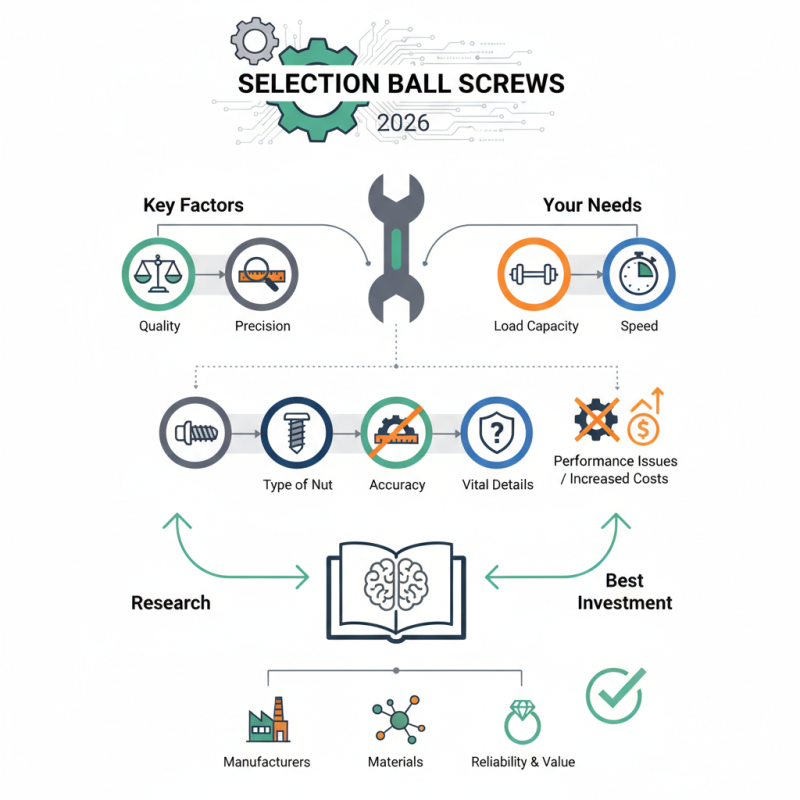

Choosing the right ball screw for sale in 2026 is crucial for your applications. John Smith, a renowned expert in the field, states, “Quality and precision are key factors when selecting ball screws.” With numerous options available, finding the best choice can feel overwhelming.

Consider your specific needs. What load capacity do you require? How fast must it operate? Each project has its unique demands, and the right ball screw can make a significant difference. Yet, many overlook vital details, such as the type of nut or the screw's accuracy. This oversight could lead to performance issues or increased costs.

As technology evolves, so do the designs of ball screws. Many options appear promising, but not every product meets high standards. Experts emphasize the importance of research. Customers must take time to compare different manufacturers and materials. The pursuit of the ideal ball screw for sale is not just about specs; it’s about finding reliability and value. Buyers should remain vigilant and question whether they are making the best investment.

Factors Influencing Ball Screw Selection in 2026: A Comprehensive Guide

Choosing the right ball screw for your application in 2026 involves several important factors. First, consider the load capacity. The International Standard ISO 3408 gives insights into load ratings. A higher load capacity often translates to better durability. However, that's not the only consideration.

Another crucial factor is the screw's accuracy. Precision is vital in fields like robotics and CNC machining. Data from the Machinery's Handbook indicates that positioning accuracy can vary significantly among available options. Users might overlook tolerance specifications. It’s essential to match them with your project requirements.

Tip: When selecting a ball screw, factor in environmental conditions. Dust, moisture, and temperature can affect performance. Not all ball screws handle these variations well.

Lastly, the ball screw's assembly and maintenance are often underestimated. A complicated setup may lead to installation errors. Studies show that improper alignment can reduce lifespan by 30%. Regular maintenance checks are key for longevity but are often neglected.

Tip: Always consult with a professional about specific application needs. A quick call can save time and resources.

How to Choose the Best Ball Screw for Sale in 2026?

| Dimension | Material | Load Capacity (N) | Lead (mm) | Accuracy Grade | Price ($) |

|---|---|---|---|---|---|

| 16 mm | Steel | 6000 | 5 | C5 | 150 |

| 20 mm | Carbon Steel | 8000 | 10 | C7 | 200 |

| 25 mm | Alloy Steel | 10000 | 12 | C3 | 250 |

| 30 mm | Stainless Steel | 12000 | 15 | C0 | 350 |

Understanding Load Capacity and Performance Ratings for Ball Screws

When selecting a ball screw, understanding load capacity is crucial. Load capacity indicates how much weight the screw can handle in various applications. It’s not just about strength; it’s about efficiency too. Misjudging load capacity can lead to failure. It’s essential to analyze the requirements carefully. If you underestimate the load, it could cause premature wear. You might observe signs of fatigue that indicate a problem.

Performance ratings also play a significant role. They provide insights into the ball screw's operational speed and precision. Higher performance ratings often signal better reliability and lifespan. However, many users overlook these ratings. They chase the cheapest option without looking at the specs. This could lead to inefficiencies in your machinery. An inappropriate choice might result in a costly downgrade later.

Consider the application environment as well. Some settings demand specific materials or coatings for durability. A basic screw might fail quickly in a demanding environment. You need to evaluate all aspects carefully. When in doubt, consult with experts or additional resources. Taking the time for this reflection can prevent future headaches.

The Role of Precision and Tolerance in Choosing Ball Screws

When choosing a ball screw, precision and tolerance play pivotal roles. Precision refers to how accurately the screw can convert rotational movement into linear motion. A higher precision level leads to smoother operation and better performance in machines. Consider how this impacts your work. If your project demands tight tolerances, then the right ball screw will significantly influence your results.

Tolerance, on the other hand, defines the acceptable range of deviation in dimensions. If the tolerance is too loose, the mechanism may not function well. Your machinery might experience backlash, leading to inaccuracies. It’s essential to balance the tolerance against the application’s requirements. In some cases, you may compromise on precision for cost-effectiveness, but this could lead to poorer performance.

Choosing the best ball screw requires reflecting on these factors. Are you prioritizing cost over precision? This could affect operational efficiency. A mismatch in precision and tolerance can result in a frustrating experience. Always assess your needs critically. The selection process isn’t merely about finding affordable options; it’s about what works best for your project.

Evaluating Material Types: Steel vs. Stainless Steel Ball Screws

When choosing ball screws, material types play a crucial role. Steel and stainless steel are common options. Steel ball screws are known for their strength. They are often less expensive than their stainless counterparts. However, they may rust in high moisture environments. This can be a significant drawback for some applications.

Stainless steel offers better corrosion resistance. It performs well in humid conditions and is ideal for food processing or medical devices. However, the cost of stainless steel ball screws can be higher. It's essential to balance performance and budget when selecting.

Tips:

Consider your working environment. If moisture is present, stainless steel is likely the better choice. Evaluate how often you will need to replace your ball screws. Sometimes, investing a bit more upfront can save costs on maintenance later. Always consult with a specialist if you’re unsure. A mismatch in materials can lead to unexpected complications.

Comparison of Steel and Stainless Steel Ball Screws

Industry Trends in Ball Screw Innovation and Technology Advancements

The landscape of ball screw technology is evolving rapidly. Industry reports predict a 5% growth in the market by 2026, driven by automation and precision demands. Innovations focus on materials that enhance durability while reducing friction. For instance, the use of composite materials is gaining traction. These materials are lighter and stronger, which can improve overall efficiency in systems.

Tips: Consider your application's requirements carefully. A higher load capacity may lead to increased wear if not matched with proper lubrication solutions.

Recent advancements also include the integration of IoT technology. Smart ball screws equipped with sensors provide real-time data on performance. This technology allows for proactive maintenance, minimizing downtime. However, as we embrace these innovations, we must ensure that data security measures are in place.

Tips: When selecting a ball screw, think about compatibility with your existing systems. Not all smart features will mesh well with every setup.

As the industry progresses, balancing innovation and practicality will be key. It’s essential to weigh the benefits of high-tech solutions against the increased complexity they may introduce.