Contact Us

10 Best Canned Pumps for Efficient Fluid Transfer in 2026?

In the dynamic world of fluid transfer, canned pumps are gaining prominence for their efficiency and reliability. According to Dr. Emily Chen, a leading expert in the pumping industry, “Canned pumps offer unique advantages, especially in maintaining system integrity.” Her insights highlight a growing trend in choosing these pumps for sensitive applications.

Canned pumps are designed to minimize leakage, a crucial benefit in various sectors. Industries like pharmaceuticals and food processing require stringent safety standards. The design of a canned pump protects against contamination, thus ensuring product integrity. However, not all canned pumps meet industry expectations. There are models that leave room for improvement, especially in durability.

Efficiency is essential. Yet, some users find certain canned pumps complex to install and maintain. Organizations must weigh initial costs against long-term benefits. Despite challenges, the future looks promising. As technology advances, we can expect even more innovations in the canned pump sector. Each advancement will continue to enhance performance and reliability in fluid transfer systems.

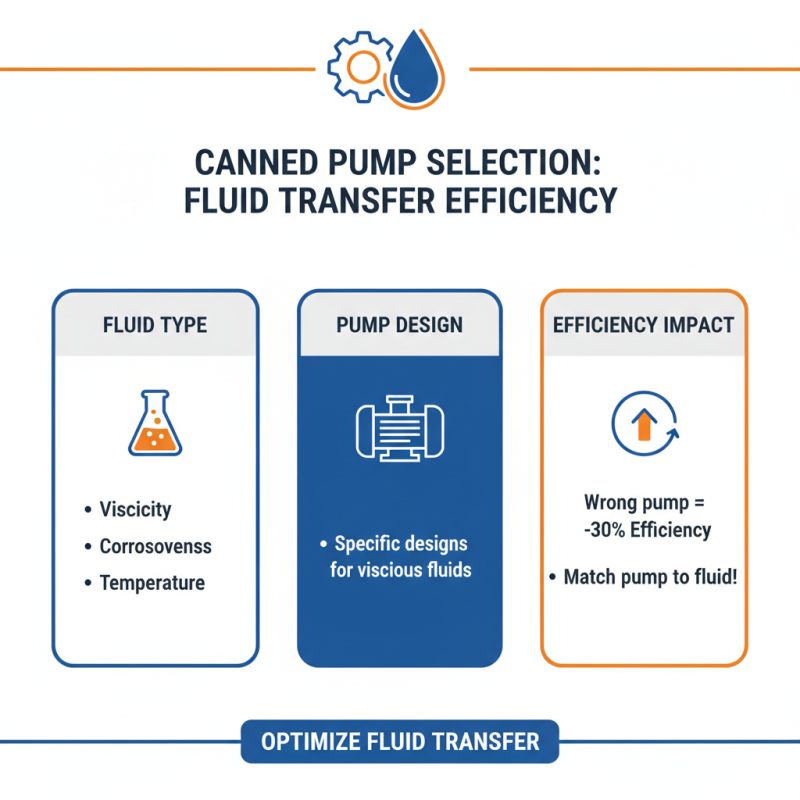

Top Factors to Consider When Choosing a Canned Pump for Fluid Transfer

When selecting a canned pump for efficient fluid transfer, several critical factors deserve attention. The type of fluid being transferred significantly impacts pump performance. Highly viscous liquids require pumps with specific designs. Reports indicate that operating with the wrong pump can decrease efficiency by up to 30%. Understanding the viscosity, corrosiveness, and temperature of the fluid is essential.

Another important factor is the pump's construction material. Materials need to withstand the operating environment. For example, using a plastic pump for harsh chemicals can lead to premature failure. Data shows that corrosion-related failures account for 15% of pump malfunctions. It's vital to consider compatibility and longevity during the selection process. Yet many overlook this, leading to costly downtime and repairs.

Additionally, the pump's flow rate impact is crucial. Employers should assess the required volume per minute. A pump that isn’t adequately sized can result in underperformance. Research suggests that oversized pumps can waste energy and overheat. Paying close attention to these details can help avoid inefficiencies. A thorough understanding of these factors can lead to better choices in pump selection.

Overview of Canned Pump Technology and Its Applications in 2026

Canned pump technology has gained popularity in fluid transfer. In 2026, this technology is expected to play a crucial role in various industries. Canned pumps provide a sealed environment, reducing leakage risks and ensuring safety during operations. According to recent industry reports, the demand for canned pumps is projected to grow by

15% annually. This growth is fueled by increasing safety regulations and a push for reliable fluid handling solutions.

Applications range from chemical processing to food and beverage production. Canned pumps can handle corrosive and viscous fluids, making them versatile. However, the technology is not without challenges. Maintenance can be complex, and users often report difficulties in troubleshooting issues. Despite these challenges, the benefits of reduced contamination and improved safety are compelling.

Many industries are investing in this technology as they adapt to evolving market demands.

In terms of efficiency, canned pumps deliver consistent performance. They typically operate at higher speeds, resulting in better fluid transfer rates. Data shows that systems using canned pumps can achieve efficiencies of up to 90%. However, installation costs can be high, leading to hesitations in adoption across smaller enterprises. The discussion around to what extent these pumps provide return on investment continues, suggesting a need for more case studies demonstrating long-term benefits.

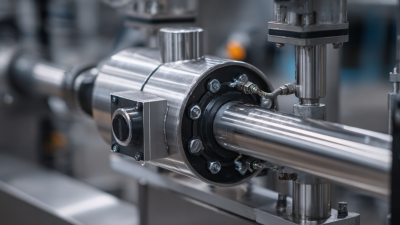

Comparison of the 10 Best Canned Pumps for Efficiency and Performance

Canned pumps have become essential tools for fluid transfer across various industries. Choosing the right pump can be challenging. Various factors impact efficiency and performance. The design of each pump significantly influences its ability to handle different fluids.

When comparing the top canned pumps, attention must be paid to flow rates and pressure capacities. Some pumps excel in lower viscosity fluids, while others are better suited for thicker substances. The materials used in construction also matter. Certain materials resist corrosion, which prolongs the pump's lifespan. When evaluating, consider how each pump performs under different temperature conditions. This can affect its efficiency.

Yet, not all options are perfect. Some pumps might struggle with specific fluid types. Additionally, installation can pose challenges for certain models. Maintenance is crucial and often overlooked. Regular checks can prevent unexpected downtime. Make note of these factors as they contribute to overall performance. As the demand for efficient fluid transfer grows, understanding these nuances will help users make informed decisions.

User Reviews and Ratings: Insights on the Leading Canned Pumps

Canned pumps are essential tools for fluid transfer in various applications. As we look toward 2026, user reviews reveal key insights into the best options available. Many users emphasize efficiency and reliability. One user noted that a particular pump managed to transfer fluids without significant loss, a crucial factor for effective operations.

However, not all pumps receive high praise. Some users noted maintenance challenges. One reviewer mentioned a model’s parts worn out quicker than expected. Feedback often highlights the importance of durability. Solid construction is vital, but not every design meets user expectations.

Rating systems show a mix of opinions. Some pumps achieve high ratings due to performance. Others lag behind due to noise or inefficiency. Many reviews stress the importance of thorough research before purchasing. Choosing the right canned pump can feel daunting. Users frequently recommend looking for models that match specific needs while ensuring reliability and longevity.

Maintenance Tips for Maximizing the Lifespan of Canned Pumps

Canned pumps are vital for fluid transfer tasks in various industries. Proper maintenance is key to maximizing their lifespan. Regular inspection of the pump's condition helps identify potential issues early. Look for signs of wear on seals and bearings. Replacing worn parts in time can prevent bigger problems down the line.

Cleaning is another important aspect of maintenance. Debris buildup can lead to inefficiency. Schedule routine cleaning of the pump's housing and intake areas. Use compatible solvents to avoid damage. Don't forget to check the fluid viscosity regularly. If it seems off, it may affect pump performance.

Documentation of maintenance activities is often overlooked. Keeping a log helps track the pump’s history. Dates and actions taken can pinpoint recurring issues. Reflecting on this history aids in better understanding. Maintenance can feel mundane, but it greatly impacts pump reliability. Emphasizing attention to detail ensures smooth operations over the long term.

10 Best Canned Pumps for Efficient Fluid Transfer in 2026

This chart represents the efficiency ratings of the top 10 canned pumps based on various factors such as flow rate, durability, and energy consumption. Higher ratings indicate better performance in fluid transfer applications.

Related Posts

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries

-

Understanding Canned Pumps: Types, Applications, and Benefits Explained

-

2026 Best Condensate Tank Options for Efficient Water Management?

-

2025 Top 10 Boiler Feed Tanks for Efficient Water Management

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Top 10 High Temperature Pump Tips You Need to Know for Efficient Operation