Contact Us

Top 5 Best High Temperature Pumps for Industrial Applications?

High temperature pumps are essential in many industrial applications. These pumps are designed to handle fluids at elevated temperatures, often exceeding 200 degrees Celsius. They are crucial in industries like chemical processing, oil and gas, and power generation. According to a recent report by MarketsandMarkets, the high temperature pump market is projected to grow substantially, highlighting their increasing importance.

Choosing the right high temperature pump is vital for operational efficiency. The wrong pump can lead to equipment failures or costly downtime. Factors such as material compatibility, maximum temperature ratings, and flow rates must be considered carefully. Many industries still struggle with these challenges. A significant number of facilities report issues with pump reliability due to improper selection.

While advancements in pump technology offer promising solutions, not all options are viable. Some high temperature pumps can be expensive, which may deter companies from upgrading. Additionally, maintenance and installation can be complex. The right approach involves weighing the costs against the benefits, ensuring a balance between performance and budget constraints.

Overview of High Temperature Pumps Used in Industries

High temperature pumps play a critical role in various industrial applications. These pumps handle fluids that reach elevated temperatures. Industries such as oil and gas, chemical manufacturing, and power generation frequently rely on them. The right pump can manage these extreme conditions effectively.

Choosing a pump involves key considerations. Materials used in pump construction must withstand high temperatures without degrading. Temperature extremes can lead to unexpected wear and tear. Regular inspection is essential to ensure reliability. Sometimes, businesses overlook the need for specific seals and gaskets. This oversight could lead to leaks or failures, causing costly downtime.

Performance is another vital aspect. High temperature pumps should maintain flow rates under challenging conditions. Variations in temperature can impact fluid viscosity. It’s crucial to understand these dynamics to avoid underperformance. Professionals must balance efficiency with durability. Many return to the drawing board after realizing their initial choices were ineffective. Therefore, thorough research and testing are indispensable in selecting the right pump.

Key Features to Consider for Industrial High Temperature Pumps

When selecting high-temperature pumps for industrial applications, certain key features are critical. The pump's temperature range is paramount. Most high-temperature pumps operate effectively between 100°C and 400°C. Beyond 400°C, materials may degrade, posing risks. Efficiency is another major factor. Pumps with higher efficiency reduce energy costs and minimize thermal stress.

Materials used in pump construction cannot be overlooked. Steel, bronze, and specialized alloys withstand high heat. A study shows that nearly 25% of pump failures result from material fatigue in high-temperature settings. Regular maintenance is vital to prevent these issues. Additionally, flow rate capabilities must match system requirements. Inadequate flow can lead to overheating and potential system failures.

Tip: Evaluate the thermal conductivity of materials. This reduces heat transfer losses. A well-designed cooling system can enhance pump longevity. Another tip is to schedule routine checks. Early detection of wear can save on costly repairs. While it’s tempting to choose the cheapest option, quality and reliability often yield better long-term value. Each choice should reflect careful consideration of the specific application needs and potential challenges.

Top 5 High Temperature Pumps: Performance and Applications

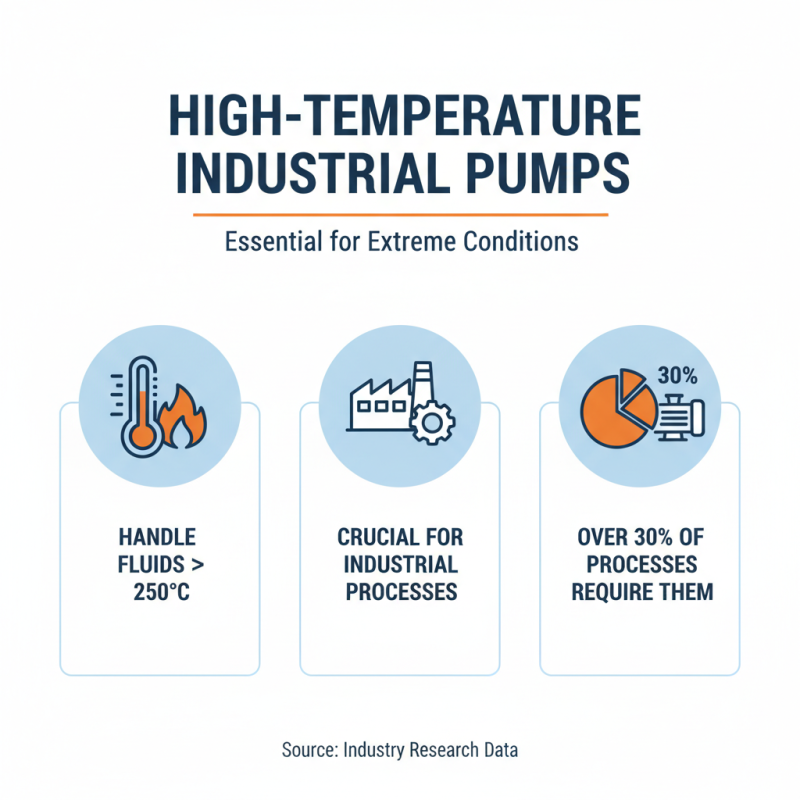

In industrial settings, high temperature pumps are essential for various applications. These pumps handle fluids at elevated temperatures, often exceeding 250°C. Research indicates that over 30% of industrial processes require pumps capable of high performance under such conditions.

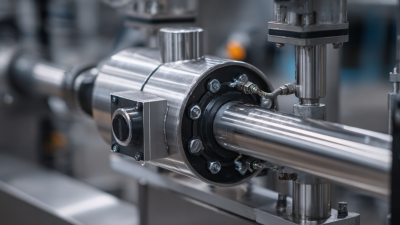

Materials matter. Many high temperature pumps use specialized alloys or ceramics. These materials withstand heat and corrosion. Pumps designed for these conditions often have mechanical seals that can manage pressure and temperature extremes. Recent reports show that improper sealing can lead to failures, costing industries thousands in repairs and downtime.

Efficiency is paramount. Studies demonstrate that high temperature pumps can lose up to 20% efficiency if not selected correctly. Employing wrong pump types can lead to overheating or inadequate fluid transfer. It’s critical to evaluate the specific application needs: flow rate, pressure, and temperature. This understanding can prevent costly manufacturing interruptions.

Comparison of Leading High Temperature Pumps in the Market

High temperature pumps play a crucial role in industrial applications. They are designed to handle fluids at elevated temperatures, often exceeding 200°C. The efficiency of these pumps can significantly impact production processes. According to a recent industry report, the demand for high temperature pumps is projected to grow by 5% annually over the next five years.

Comparing leading models reveals differences in materials and design. Some pumps use ceramic coatings to enhance thermal resistance, while others rely on specialized seals to prevent leaks. A study indicated that pumps with advanced sealing mechanisms can reduce operational failures by up to 30%. However, many manufacturers still overlook the importance of regular maintenance. Neglect can lead to reduced efficiency and increased costs.

The choice of pump also depends on the specific application. Applications in chemical industries often require pumps that can handle corrosive substances at high temperatures. Many pumps lack the versatility needed for diverse industrial settings. This limitation poses a challenge for industries seeking reliable solutions. Continuous innovation is necessary, but many companies remain hesitant to invest in newer technologies, risking inefficiencies in the long run.

Comparison of Top 5 High Temperature Pumps for Industrial Applications

Maintenance Tips for Optimal Performance of High Temperature Pumps

High-temperature pumps play a crucial role in various industrial processes. They are essential for transporting fluids at elevated temperatures. Proper maintenance ensures these pumps operate efficiently and have a longer lifespan. Regularly checking seals and gaskets is vital. A damaged seal can lead to leaks, which can drastically affect performance.

According to industry reports, nearly 30% of pump failures are attributed to improper maintenance. It’s important to monitor the pump’s temperature regularly. Overheating can cause significant wear and reduce the pump’s efficiency. Lubrication is key. Utilizing the right type of lubricant reduces friction and heat generation. Ensure that all bearings are well-lubricated to prevent breakdowns.

Vibration analysis can help detect early signs of trouble. High vibration levels often signal underlying issues. Implementing a routine inspection schedule will help identify potential problems before they escalate. Adhering to maintenance tips can avoid unexpected downtimes. High-temperature pumps can be efficient, but they demand attention and care. Small oversights can lead to costly repairs or replacements. Keep a close eye on performance metrics to ensure optimal operation.

Related Posts

-

2026 How to Choose the Right Commercial Condensate Pump for Your Needs?

-

Top 10 Small Centrifugal Pumps for Efficient Water Management in 2023

-

Top 10 Steam Condensate Pumps for Efficient Energy Management?

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance