Contact Us

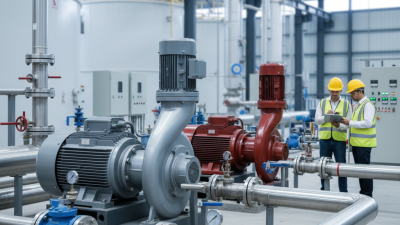

Best Types of Centrifugal Pump for Various Applications?

Centrifugal pumps are essential in various industries due to their efficiency and reliability. Various types of centrifugal pump cater to specific applications, each designed for unique requirements. According to a recent industry report, the global centrifugal pump market is expected to grow significantly, reaching over $45 billion by 2025. This growth reflects an increasing need for efficient fluid handling in sectors like water treatment, oil and gas, and chemical processing.

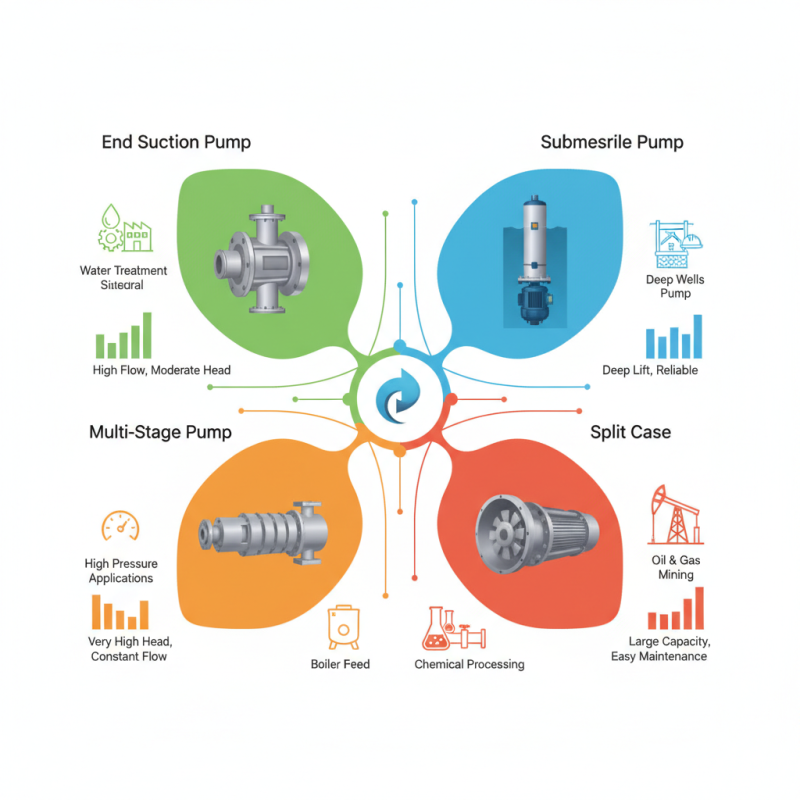

Understanding the best types of centrifugal pump is crucial for maximizing performance. Each type comes with its own advantages and limitations. For example, end suction pumps are widely used for their simple design and cost-effectiveness. However, they may not perform well in extremely high-pressure situations. Submersible pumps, while excellent for deep well applications, can pose challenges with maintenance and operational efficiency.

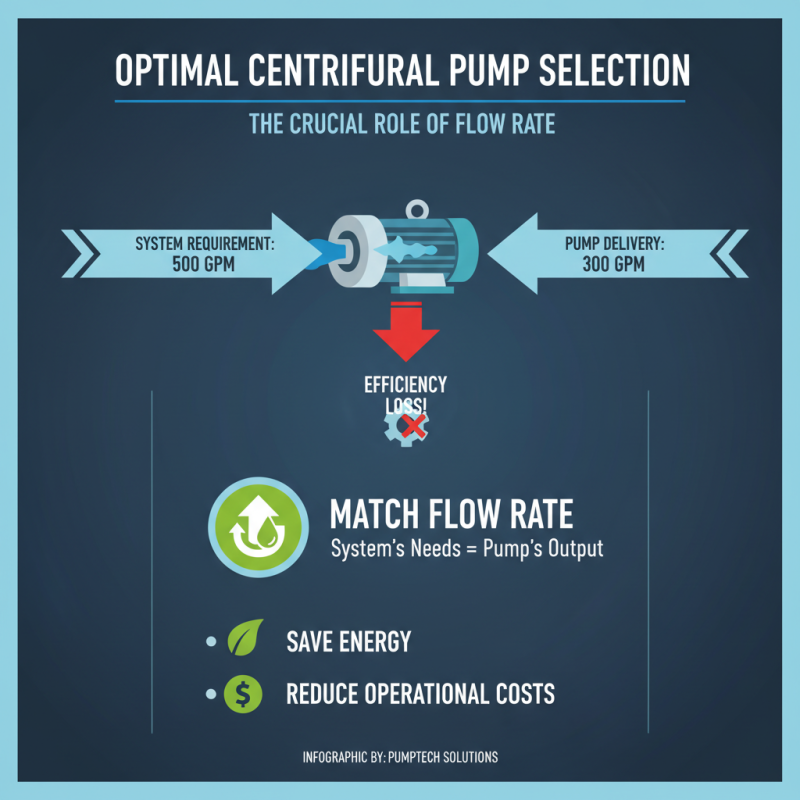

Selecting the right pump type can often feel overwhelming. Many factors influence the choice, including flow rate, fluid properties, and operational environment. It's essential to evaluate these aspects thoroughly. A well-informed decision can lead to optimal system performance and reliability. A misstep here may result in inefficiencies or increased operational costs. Therefore, recognizing the strengths and weaknesses of the various types of centrifugal pump is vital.

Understanding Centrifugal Pumps: Basic Principles and Functionality

Centrifugal pumps are crucial in many industries. They operate on simple principles. A rotating impeller spins, creating a low-pressure area. Fluid is drawn in from the inlet and pushed out through the outlet. This movement relies on centrifugal force. It’s effective for liquids of various viscosities.

In many applications, the design of the pump matters. For example, some pumps work well with clean water. Others handle slurries or corrosive chemicals. Selecting the right type can be challenging. Factors like flow rate and fluid properties must be considered. Sometimes, it’s easy to overlook these details.

Understanding your needs is vital. Size, efficiency, and head pressure play pivotal roles. A pump that fits one application might fail in another. Minor miscalculations can lead to inefficiencies. It’s important to reflect on requirements before making a choice. Each application has its unique demands, making this decision complex.

Common Applications for Centrifugal Pumps in Various Industries

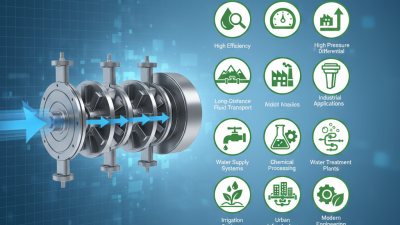

Centrifugal pumps are widely used across various industries. They are essential in moving liquids efficiently. In the water treatment sector, these pumps help in transferring clean water and wastewater. They ensure proper flow rates for filtration and distribution. Whether it's for urban supply or agricultural needs, the demands are ever-changing.

In the chemical industry, applications are diverse. Centrifugal pumps handle corrosive liquids effectively. They are crucial for processes like mixing, transferring, and even dosing chemicals. However, not all pumps are suitable for every chemical. Choosing the right material is vital. This can be a tough decision, as not all data is clear.

In food production, safety is paramount. Centrifugal pumps must adhere to strict hygiene standards. They are used to transfer liquids like juices or oils. The design often complicates cleaning processes. This sometimes leads to contamination risks. Regular maintenance and monitoring can help address these concerns, but the challenge remains a topic of discussion.

Types of Centrifugal Pumps and Their Specific Use Cases

Centrifugal pumps are crucial in many industries. Their design suits various applications. One common type is the single-stage centrifugal pump. These pumps are ideal for clean water. They excel in agricultural irrigation systems. According to industry reports, they provide flow rates up to 5000 gallons per minute.

Multi-stage centrifugal pumps are versatile as well. These pumps increase pressure, making them suitable for high-rise buildings and boiler feed applications. They handle water and other fluids, but not all fluids. Some require special materials for safety. Maintenance can also be an issue, potentially leading to increased costs.

Another variant is the submersible centrifugal pump. These pumps work underwater and are commonly used in wastewater management. While effective, they require regular inspection. Failure to maintain them can lead to serious environmental issues. Users must weigh the benefits and drawbacks carefully. Each type has unique characteristics, affecting its usability in specific scenarios.

Factors to Consider When Selecting a Centrifugal Pump

Choosing the right centrifugal pump involves several key factors. Flow rate is crucial. It must match your system's requirements. For example, a facility may need 500 GPM, but if the pump only delivers 300 GPM, efficiency drops. Selecting a pump that can handle the specific flow rate of your application can save energy and reduce operational costs.

Next, consider the fluid characteristics. Temperature, viscosity, and corrosiveness can greatly affect performance. A high-viscosity fluid may require a more robust pump design. According to industry studies, 30% of pump failures relate to cavitation caused by incorrect fluid handling. This highlights the importance of analyzing the fluid before selection.

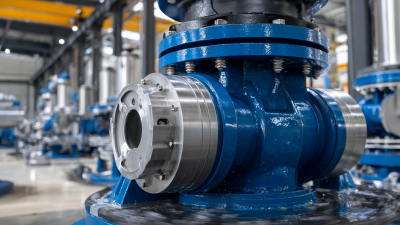

Finally, maintenance and reliability are vital. Pumps can operate in harsh conditions. Regular maintenance can lead to prolonged lifespan. Reports show that unplanned downtime can cost organizations up to $1 million, significantly impacting overall productivity. Selecting a centrifugal pump with a design that minimizes wear and regular maintenance is essential for avoiding costly failures.

Maintenance Practices for Ensuring Optimal Performance of Pumps

Routine maintenance is critical for ensuring the optimal performance of centrifugal pumps. According to a report by the Hydraulic Institute, regular inspection can reduce operational failures by up to 30%. This emphasizes the need for a systematic approach to pump care. Proper lubrication of moving parts is essential. Without adequate lubrication, wear increases significantly. This can lead to costly downtime and repairs.

Monitoring vibration levels and temperature can provide early warning signs of issues. Sudden changes in these metrics often indicate problems with bearings or alignment. A study revealed that 40% of pump failures stem from misalignment issues. Environmental factors also play a role. For instance, dirt and debris can clog filters, decreasing efficiency. Periodic cleaning can prevent this.

An overlooked aspect is documentation. Keeping records of maintenance activities is crucial. This creates a reference for future troubleshooting. It also helps identify recurring issues that might need more attention. Consistent maintenance practices help prolong pump life, enhancing reliability. Ignoring these can result in more frequent failures and unexpected costs.

Best Types of Centrifugal Pump for Various Applications

| Application | Best Type of Centrifugal Pump | Key Features | Maintenance Practices |

|---|---|---|---|

| Water Supply | End Suction Pump | Simple design, high efficiency | Regularly check seals and bearings |

| Chemical Handling | Magnetic Drive Pump | Leak-free operation, corrosion resistant | Inspect impellers and casing for wear |

| HVAC Systems | Vertical Inline Pump | Space-saving design, efficient flow | Clean strainers and check motor alignment |

| Irrigation | Self-Priming Pump | High suction lift capability, durable construction | Check for cavitation and clogged filters |

| Fire Protection | Split Case Pump | High flow capacity, low maintenance | Test pump operation regularly |

Related Posts

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

7 Essential Tips for Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Top 10 Multistage Centrifugal Pump Benefits and Applications You Should Know

-

2026 How to Choose the Right Industrial Centrifugal Pumps for Your Needs?

-

The 5 Best Centrifugal Pumps for Efficient Fluid Transfer?