Contact Us

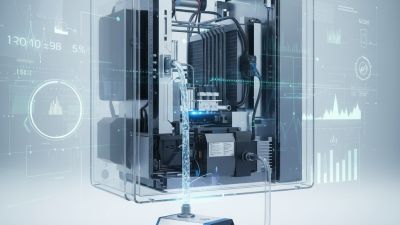

Why Is a Boiler Feed Water Pump Essential for Efficient Steam Generation?

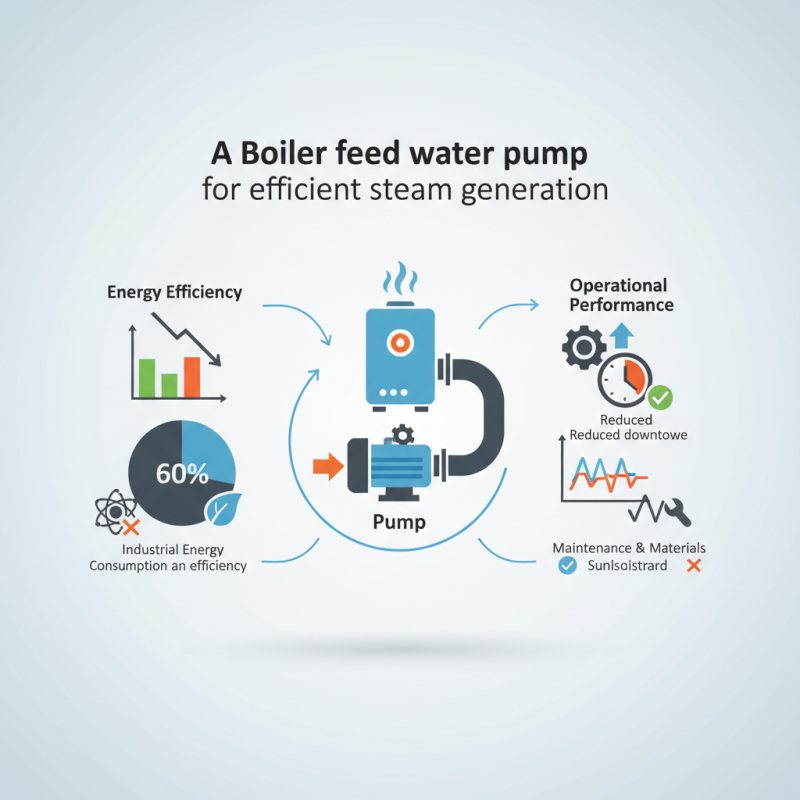

In industrial settings, a boiler feed water pump plays a critical role in steam generation efficiency. According to a report from the International Energy Agency, steam generation accounts for nearly 60% of industrial energy consumption. The performance of the boiler feed water pump directly impacts the overall energy efficiency of a boiler system. Inefficient pumps can lead to increased energy costs and carbon emissions.

Moreover, outdated pump technologies often result in operational challenges. A survey from the Pump Manufacturers Association indicated that about 30% of industrial pumps are less efficient than they could be. This inefficiency negatively affects steam production rates and system reliability.

Inadequate maintenance or the use of substandard materials further complicates the issue. These factors can compromise the steady supply of water to the boiler, leading to fluctuating steam pressure. Such inconsistencies hinder production processes and increase downtime. Awareness of these issues is essential for optimizing energy use and operational performance in steam generation.

The Role of Boiler Feed Water Pumps in Steam Generation Efficiency

Boiler feed water pumps play a crucial role in steam generation efficiency. These pumps deliver water to the boiler, ensuring it is filled properly. Without them, steam generation would face significant obstacles, leading to inefficiencies.

When the pump works optimally, steam can be produced reliably. If the pump fails or operates erratically, it can cause pressure drops. This disruption leads to uneven steam production. Fluctuating steam pressure can impact overall system performance. Inconsistent steam can result in poor heating and operational delays.

Regular maintenance of these pumps is necessary. Small leaks or wear can lead to failures. Neglecting these issues can cause inefficient steam cycles. Attention to detail is vital here. Small gains can optimize the entire system. In the realm of steam generation, every drop counts.

Boiler Feed Water Pump Contribution to Steam Generation Efficiency

This chart illustrates the impact of various factors related to boiler feed water pumps on steam generation efficiency. The pump size and flow rate have the highest impact, demonstrating the crucial role these pumps play in optimizing steam production.

How Boiler Feed Water Pumps Operate in Power Plants

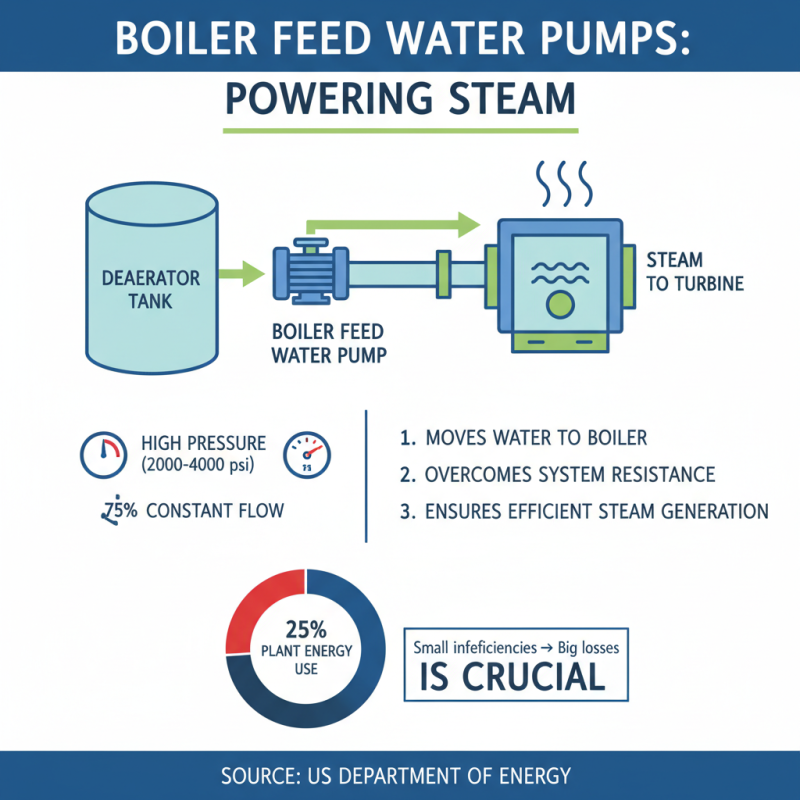

Boiler feed water pumps are vital in power plants, ensuring efficient steam generation. These pumps move water from storage tanks to boilers under high pressure. The pressure is crucial for overcoming resistance in the system and maintaining a constant flow. According to a report by the U.S. Department of Energy, energy consumption in water pumping can account for 25% of a plant's total energy use. A small inefficiency here can lead to significant losses.

Understanding their operation reveals complexities. The pumps use various configurations, including centrifugal and positive displacement types. Efficiency decreases if the pump operates outside its optimal range. For example, a pump running at less than 70% of its capacity can waste energy. In many cases, operators overlook maintenance schedules, leading to performance drops. In fact, a study indicated that nearly 30% of pump failures are attributed to improper maintenance.

Effective monitoring systems can enhance pump performance. Sensors and smart technologies help detect issues early. Yet, many plants still rely on outdated practices. Regularly updating equipment is often neglected. This reluctance can be costly. A proactive approach is essential for maintaining efficiency. The reliability of these pumps directly impacts steam production and overall plant efficiency.

Key Benefits of Using High-Quality Boiler Feed Water Pumps

Boiler feed water pumps play a crucial role in steam generation efficiency. High-quality pumps ensure precise water delivery, which is vital for maintaining optimal boiler performance.

According to industry reports, an efficient boiler feed pump can reduce energy consumption by up to 15%. This not only lowers operational costs but also minimizes environmental impact.

Using reliable pumps enhances system reliability. Inconsistent water flow can lead to boiler failures, causing downtime and costly repairs. A study from the American Society of Mechanical Engineers indicates that improper water feed can increase maintenance costs by 20%. Choosing durable materials and engineering designs is essential.

Moreover, high-quality pumps help maintain water quality. Impurities can corrode boiler components, reducing lifespan. A report from the National Association of Corrosion Engineers highlights that effective feed water treatment can extend component life by as much as 30%. Ultimately, investing in a robust boiler feed water pump is not just about compliance; it's about fostering long-term efficiency and sustainability in steam generation.

Common Challenges Faced by Boiler Feed Water Pumps

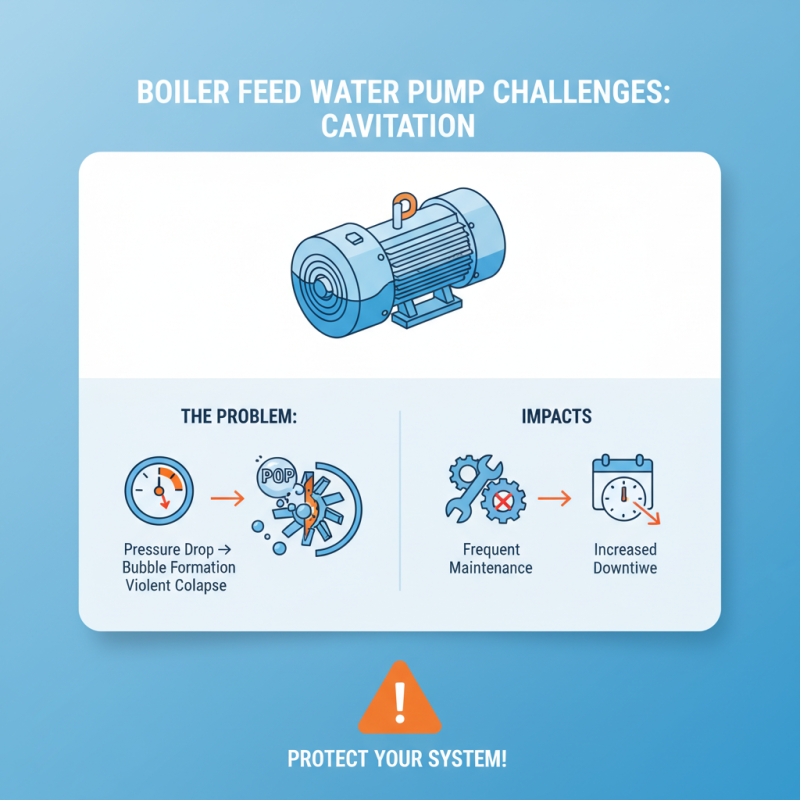

Boiler feed water pumps play a crucial role in steam generation. However, they face various challenges that can hinder performance. One significant issue is cavitation. This occurs when the pressure drops, causing bubbles to form. These bubbles collapse violently, damaging the pump components. This problem can lead to frequent maintenance, increasing downtime.

Another challenge is dealing with varying water quality. Impurities in the feed water can cause corrosion and scaling in the pump. This reduces efficiency and shortens the pump's lifespan. Monitoring water quality is essential, but not always straightforward. Many facilities struggle with this aspect, leading to unanticipated failures.

Pressure fluctuations are also a common concern. Sudden changes can strain the pump, affecting the flow rate. If not managed properly, this can disrupt the entire steam generation process. Many operators overlook these fluctuations, which can result in inefficient operations. Awareness and proactive measures are critical for maintaining pump performance.

Maintenance Practices for Optimal Boiler Feed Water Pump Performance

Boiler feed water pumps play a crucial role in steam generation. Proper maintenance is essential for their efficiency. Routine checks help identify any wear and tear. Regular inspections should focus on seals, bearings, and impellers. Addressing minor issues can prevent major failures later.

Monitoring the pump’s performance is vital. Keep track of flow rates and pressure levels. Sudden changes may indicate underlying problems. Regular cleaning of the pump and its components is also necessary. Dirt buildup can hinder performance.

Operators should be aware of common pitfalls. Neglecting scheduled maintenance might lead to costly outages. It’s essential to train staff on best practices. Having a detailed maintenance log can aid in identifying trends over time. Ultimately, optimal performance hinges on vigilance and consistent care.

Why Is a Boiler Feed Water Pump Essential for Efficient Steam Generation?

| Dimension | Measurement | Importance |

|---|---|---|

| Flow Rate | 1000-2000 GPM | Ensures adequate water supply to the boiler for steam generation. |

| Operating Pressure | 50-150 psi | Maintains proper water circulation and prevents cavitation. |

| Temperature | 150-212°F | Prevents thermal shock and ensures optimal operation. |

| Power Consumption | 5-10 kW | Minimizes energy costs and enhances efficiency. |

| Maintenance Frequency | Quarterly | Ensures reliability and extends pump life. |

Related Posts

-

What Are the Key Tips for Effective Condensate Return Tank Management?

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know

-

What is a High Pressure Water Pump and How Does It Work

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023