Contact Us

Understanding Canned Pumps: Types, Applications, and Benefits Explained

Canned pumps have emerged as a crucial innovation in various industrial applications, offering a unique combination of reliability and safety in handling fluids. According to a recent market analysis by Research and Markets, the global canned pump market is expected to grow significantly, with a projected CAGR of over 5% from 2023 to 2030. This growth is driven by the increasing demand for high-efficiency pumping solutions in sectors such as oil and gas, chemical processing, and water management.

Industry expert Dr. Jane Smith, a prominent consultant in pump technology, notes, "Canned pumps provide unparalleled benefits in terms of reducing maintenance costs and enhancing operational safety, especially in volatile environments." With their hermetically sealed design, canned pumps effectively eliminate the risk of leaks and contamination, addressing critical concerns in various industries. This article delves into the different types of canned pumps, their applications, and the myriad benefits they offer, providing a comprehensive understanding of why these pumps are becoming a preferred choice for many industrial processes.

Types of Canned Pumps: A Comprehensive Overview for Industry Professionals

Canned pumps are specialized devices designed to handle various fluids, commonly utilized in industrial applications due to their efficient and reliable performance. The primary types of canned pumps include magnetic drive pumps, sealless pumps, and centrifugal pumps, each tailored for specific operational needs. Magnetic drive pumps are known for eliminating the need for mechanical seals, reducing maintenance requirements and the risk of leaks. Sealless pumps, on the other hand, are engineered to contain the fluid within a closed system, making them ideal for handling hazardous or corrosive materials. Centrifugal canned pumps leverage centrifugal force to move fluids, providing a steady and continuous flow, suitable for various pressure applications.

In terms of applications, canned pumps are widely employed in sectors such as chemical processing, oil and gas, pharmaceuticals, and water treatment. Their ability to operate in challenging environments and their inherent safety features make them a preferred choice for transferring hazardous or sensitive liquids. Additionally, the compact design of canned pumps facilitates easy installation in constrained spaces, allowing for flexibility in system design. As industries continue to prioritize sustainability, the energy-efficient nature of canned pumps contributes significantly to reducing operational costs while minimizing environmental impact.

Understanding Canned Pumps: Types and Applications

Key Applications of Canned Pumps in Various Industries and Processes

Canned pumps are gaining prominence across various industries due to their unique design and functionality. Their hermetically sealed construction makes them ideal for applications involving hazardous or corrosive fluids, such as in the chemical and pharmaceutical sectors. In these industries, canned pumps reduce the risk of leaks, ensuring both safety and environmental protection. Additionally, they are well-suited for transferring viscous substances, providing reliable performance in various processing conditions.

In the food and beverage industry, canned pumps are particularly valuable. They are used for sanitary fluid transfer, helping to maintain product integrity and quality. Their ability to handle delicate processes without compromising on hygiene standards is crucial for minimizing contamination risks. Similarly, in wastewater treatment, canned pumps effectively manage the movement of both clear and dirty water, contributing to efficient and safe processing.

Tips: When selecting a canned pump for your application, consider factors such as fluid properties, temperature, and pressure requirements to ensure optimal performance. Regular maintenance is also essential to prolong your pump’s life and efficiency. Additionally, engage with industry experts to gain insights tailored to your specific needs, ensuring you make an informed decision that enhances operational efficiency.

Benefits of Canned Pumps: Efficiency, Safety, and Environmental Impact

Canned pumps have gained significant traction in various industries due to their unique advantages related to efficiency, safety, and environmental impact. One of the primary benefits of these pumps is their ability to operate under challenging conditions without the risk of leaks. The design encapsulates the rotating elements, effectively isolating the working fluid from the environment. This containment minimizes the risk of contamination and enhances the overall efficiency, as there is no loss of fluid or pressure during operation. These pumps also tend to have lower maintenance requirements, resulting in less downtime and increased productivity.

Safety is another crucial aspect of canned pumps. By eliminating the need for external seals and reducing the potential for leaks, they significantly lower the chances of hazardous material spills. This feature is particularly important in industries that handle toxic or corrosive substances. Furthermore, the compact design of canned pumps can help to reduce the risk of accidents in the workplace, contributing to a safer operational environment.

Environmental impact is a growing concern for many industries today. Canned pumps are designed to be more environmentally friendly, as they can reduce waste and energy consumption. Their efficiency leads to less energy being required for operation, lowering carbon footprints. Additionally, the containment of fluids minimizes the likelihood of pollution, making them a more sustainable choice in sectors aiming to meet strict environmental regulations. Overall, the benefits of canned pumps extend beyond mere functionality, aligning with modern demands for safety and environmental stewardship.

Understanding Canned Pumps: Types, Applications, and Benefits Explained

| Type | Applications | Benefits |

|---|---|---|

| Canned Motor Pumps | Chemical Processing, Water Treatment | High Efficiency, Low Leakage Risk |

| Submersible Canned Pumps | Wastewater Management, Irrigation Systems | Compact Design, Reduced Noise |

| Vertical Canned Pumps | Hydraulic Systems, HVAC Applications | Space-Saving, Easy Maintenance |

| Magnetic Drive Canned Pumps | Pharmaceuticals, Food Processing | Enhanced Safety, Zero Emissions |

| Cantilever Canned Pumps | Mining, Heavy Industry | Robust Design, Reduced Downtime |

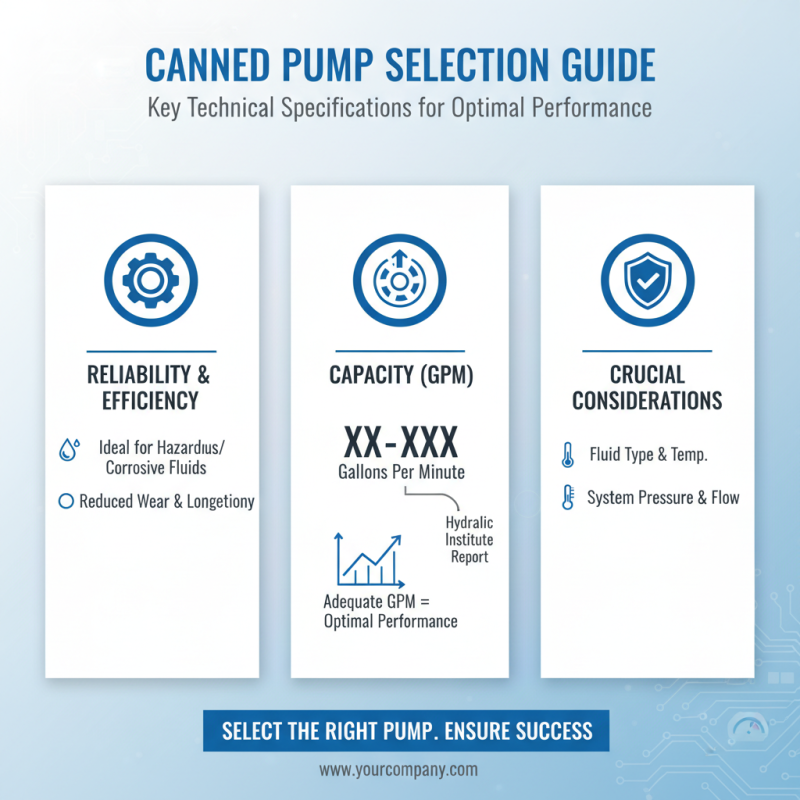

Technical Specifications: How to Choose the Right Canned Pump for Your Needs

When selecting the right canned pump for your applications, understanding the technical specifications is crucial. Canned pumps are renowned for their reliability and efficiency, particularly in industries requiring the transport of hazardous or corrosive fluids. A key factor to consider is the pump’s capacity, typically measured in gallons per minute (GPM). For example, a report from the Hydraulic Institute indicates that selecting a pump with an adequate GPM is essential for optimal performance and longevity, as undersized pumps can lead to increased wear and inefficiencies.

Another important specification is the operating pressure and temperature range. Canned pumps are designed to withstand varying levels of pressure, and elevating temperature thresholds can significantly affect pump performance. According to the American Society of Mechanical Engineers, the right selection ensures not only the pump’s operational stability but also its safety during peak conditions. Additionally, understanding the materials used in construction—such as stainless steel or reinforced plastics—can help in choosing a pump with the right corrosion resistance properties for your specific application.

Finally, consider the installation requirements and maintenance needs of the canned pump. Opting for a design that integrates easily into existing systems while minimizing maintenance downtime can bring significant operational advantages. Data from industry surveys show that organizations that prioritize these specifications experience a decrease in lifecycle costs by up to 25%, thereby improving both efficiency and profitability in operations.

Trends and Innovations in Canned Pump Technology: What to Expect in 2024

As we move into 2024, the canned pump technology landscape is evolving rapidly, reflecting advancements in materials, design, and energy efficiency. One notable trend is the increased use of advanced composite materials that enhance resistance to both corrosion and heat, allowing for a wider range of fluid applications. These materials not only prolong the lifespan of the pumps but also reduce maintenance costs. Furthermore, manufacturers are focusing on creating modular designs that facilitate easy maintenance and customization, enabling users to adapt their systems to specific operational needs with minimal downtime.

Innovations in sensor technology and smart monitoring systems are also making waves in the canned pump sector. By integrating real-time monitoring capabilities, operators can gain valuable insights into performance metrics, detect potential issues before they escalate, and optimize energy consumption. This shift towards automation and predictive maintenance is expected to enhance overall operational efficiency and reliability, making canned pumps an even more attractive solution for industries ranging from chemical processing to oil and gas. As these technologies continue to develop, the future holds significant promise for improving the performance and adaptability of canned pumps across various applications.

Related Posts

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

Best High Pressure Pumps for Water in 2023 Top Options Reviewed

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance