Contact Us

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

In the realm of industrial heating systems, the boiler condensate pump plays a crucial role in ensuring optimal performance and operational efficiency. As emphasized by John Smith, a leading expert in boiler systems, “A well-maintained boiler condensate pump is essential for preventing system failures and maximizing energy efficiency.” Understanding how to choose and maintain these pumps is key to their longevity and effective functioning.

When selecting a boiler condensate pump, various factors come into play, including capacity, material compatibility, and maintenance requirements. An effective choice not only enhances performance but also reduces overall costs and downtime. Proper maintenance practices, such as regular inspections and timely repairs, are equally vital to sustain the pump's efficiency over time, preventing issues that could escalate into significant operational disruptions.

Investing time and resources into understanding the intricacies of the boiler condensate pump ensures that facility managers can make informed decisions. By adhering to expert recommendations and best practices, users can optimize their heating systems, ensuring a seamless operation that supports their broader energy management goals.

Choosing the Right Boiler Condensate Pump for Your Needs

When choosing a boiler condensate pump, it is essential to consider the specific requirements of your heating system. First, assess the volume of condensate the pump needs to handle, which is influenced by the size and efficiency of your boiler. A pump with an appropriate capacity will ensure that it can effectively manage the water generated during the condensation process, preventing any overflow or system strain. Additionally, consider the height the pump must lift the condensate, as this will affect your choice of model. Higher lift capabilities usually indicate a more powerful, and sometimes larger, pump.

Another important factor is the material and design of the pump. Ensure that the pump is built with corrosion-resistant materials to withstand the acidic nature of condensate. Selecting a model designed for efficient operation helps minimize energy consumption and boosts overall system performance. Furthermore, review the maintenance requirements of the pump; some models offer easier access for servicing, which can save time and cost in the long run. Reflecting on these considerations will lead to an informed decision that aligns with your operational needs and promotes the longevity of your heating system.

Boiler Condensate Pump Selection and Maintenance Data

Key Features to Consider When Selecting a Condensate Pump

When selecting a condensate pump, several key features should be taken into account to ensure optimal performance and longevity. One of the most important factors is the pump's capacity, which should match the requirements of the boiler system. According to the American Society of Mechanical Engineers (ASME), a condensate pump typically operates best within a specified flow range that corresponds to the boiler's heating output. For instance, a pump with a higher flow rate can efficiently manage larger volumes of condensate, reducing the risk of overflow and system failures.

Another critical aspect to consider is the material construction of the pump, which should be durable and corrosion-resistant. Many condensate pumps are subject to high temperatures and corrosive environments, and selecting a model made from stainless steel or other resilient materials can significantly extend its service life. In a survey by the National Association of Boiler Operators, nearly 30% of pump failures were attributed to corrosion, emphasizing the need for robust materials in pump selection.

Tips:

1. Always refer to the manufacturer's specifications for compatibility with existing systems to avoid costly mismatches.

2. Regular maintenance, including cleaning filters and checking for wear, can prevent many common issues and improve operational efficiency over time.

3. Consider energy efficiency ratings of the condensate pump, as more efficient models can help reduce operational costs significantly, contributing to long-term savings.

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

| Feature | Description | Importance |

|---|---|---|

| Pump Capacity | The amount of condensate the pump can handle per hour. | Ensures the pump can efficiently manage the condensate produced. |

| Material | The casing material that affects durability and corrosion resistance. | Affects longevity and performance in harsh environments. |

| Float Switch Type | Type of float switch used for operational control (mechanical, electronic). | Influences reliability and accuracy of operation. |

| Power Supply | Voltage and type (single-phase or three-phase) required for the pump. | Essential for compatibility with existing systems. |

| Size and Weight | Dimensions and weight of the pump for installation considerations. | Affects installation space and structural support requirements. |

| Maintenance Requirements | Frequency and complexity of maintenance tasks. | Influences ongoing costs and operational reliability. |

| Noise Level | Sound level produced during operation. | Important for installation in noise-sensitive environments. |

| Cost | Initial purchase price and expected operational costs. | Affects budget and overall economic efficiency. |

Installation Guidelines for Optimal Performance of Condensate Pumps

When installing a boiler condensate pump, it is essential to follow specific guidelines to ensure optimal performance and longevity. First, select an appropriate location for the pump that is close to the boiler and complies with the manufacturer's specifications. Ensure that the area is clean, dry, and well-ventilated to prevent any overheating or accumulation of moisture that could affect the pump’s operation. The pump should be installed on a solid, level surface to minimize vibration and noise during operation.

Next, proper plumbing connections are crucial for the efficient functioning of the condensate pump. Use high-quality piping materials that are resistant to corrosion and can handle the temperature of the condensate. Ensure that the discharge line is appropriately sized and routed to avoid any unnecessary bends or obstructions, which could impede the flow of condensate. Additionally, it’s important to install check valves to prevent backflow and maintain the efficiency of the system. Regular inspection and maintenance of these connections can prevent leaks and ensure smooth operation.

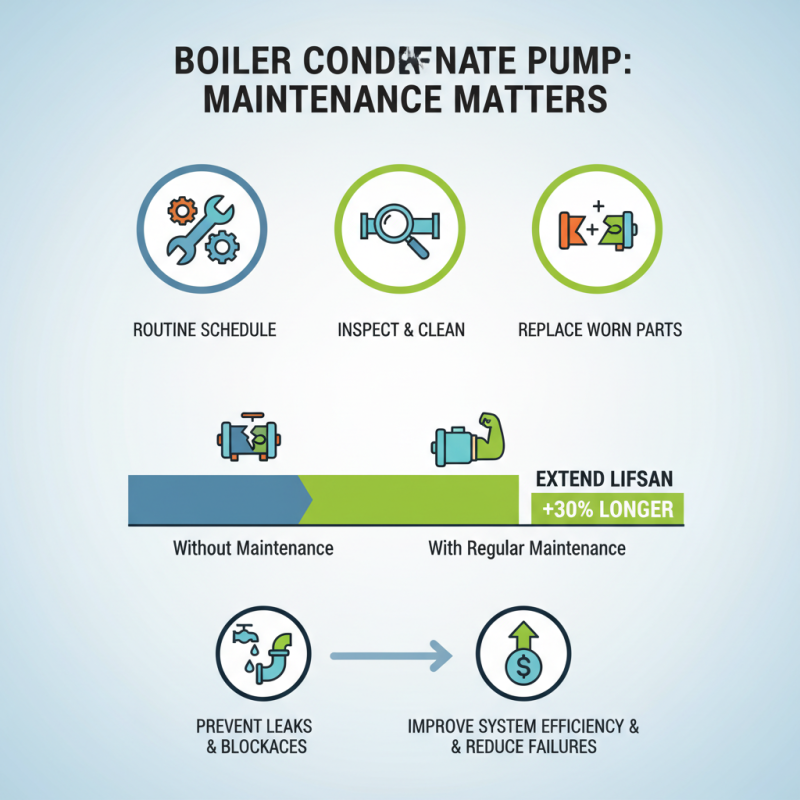

Routine Maintenance Tips to Ensure Long-lasting Pump Efficiency

Maintaining a boiler condensate pump is crucial for ensuring optimal performance and longevity. According to industry reports, regular maintenance can extend the lifespan of these pumps significantly, reducing unexpected failures by up to 30%. To achieve this, operators should establish a routine maintenance schedule that includes regular inspections, cleaning, and replacement of worn-out parts. Checking for leaks or blockages in the pump and piping can prevent major operational disruptions and improve overall system efficiency.

Tips: One effective maintenance tip is to inspect the float switch regularly. A malfunctioning float switch can lead to improper water levels within the condensate return system, potentially damaging the pump. Additionally, cleaning the pump strainer and verifying the functionality of the check valve ensures smooth operation by preventing debris accumulation, which is a common cause of pump inefficiency.

Another important aspect of maintenance is monitoring the pump's performance metrics. Keeping track of parameters such as flow rate and pressure can help identify any deviations from norm, allowing for timely interventions. Research indicates that consistent performance monitoring can increase energy efficiency by 15%, further emphasizing the necessity of rigorous maintenance practices.

Common Issues and Troubleshooting for Boiler Condensate Pumps

Boiler condensate pumps play an essential role in maintaining the efficiency of boiler systems by effectively removing condensate. However, like any equipment, these pumps can run into issues that need troubleshooting. Common problems include pump failure, clogs, and improper functioning due to issues with the check valve or float switch. Regular maintenance and timely identification of these problems are crucial to ensure optimal performance.

Tips for troubleshooting include regularly inspecting the pump for signs of wear and tear, such as leaks or unusual noises. Additionally, ensure the check valve is functioning properly to prevent backflow, and that the float switch is free from obstructions. If the pump is not activating, check the power supply, as electrical issues often lead to pump failure. Keeping a clean and clutter-free environment around the pump can also help minimize potential problems.

Implementing a routine maintenance schedule can greatly reduce the likelihood of issues arising. This includes flushing the pump periodically to remove accumulated debris and checking all seals and connections for signs of wear. By staying vigilant and proactive about maintenance, you can extend the life of your boiler condensate pump and enhance overall system efficiency.

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

7 Essential Tips for Choosing the Right Vertical Centrifugal Pump for Your Needs