Contact Us

How to Choose the Right Steam Condensate Return Pump for Your System?

Choosing the right steam condensate return pump is crucial for any steam system. According to industry expert John Adams, "The effectiveness of your steam system relies heavily on a well-selected condensate return pump." This insight emphasizes the importance of understanding your system's specific demands.

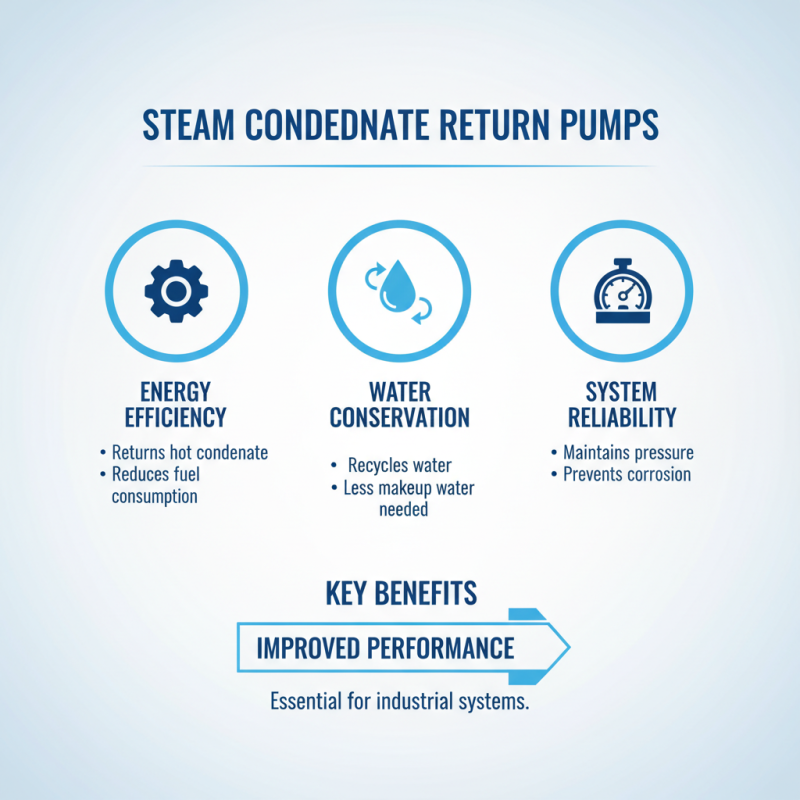

Steam condensate return pumps play a vital role in maintaining efficiency. They help recycle condensed steam back into the boiler, reducing energy waste and improving overall performance. Yet, many facilities overlook the details when selecting a pump. It's not just about horsepower or capacity. Factors like temperature and pressure ratings can make or break your system's efficiency.

Selecting the perfect steam condensate return pump requires careful consideration. Many engineers often rush this decision. They focus on brochures and specifications but fail to account for real-world conditions. This can lead to premature pump failures or inefficiencies. A hands-on approach and consulting with professionals can mitigate such risks. Rethinking your pump choice can save energy and costs in the long run.

Understanding the Role of Steam Condensate Return Pumps in Systems

Steam condensate return pumps play a crucial role in industrial systems. They efficiently return condensate to the boiler for reuse. This process improves energy efficiency and reduces water consumption. The return of condensate is vital for maintaining system pressure. A well-functioning pump helps in achieving these goals.

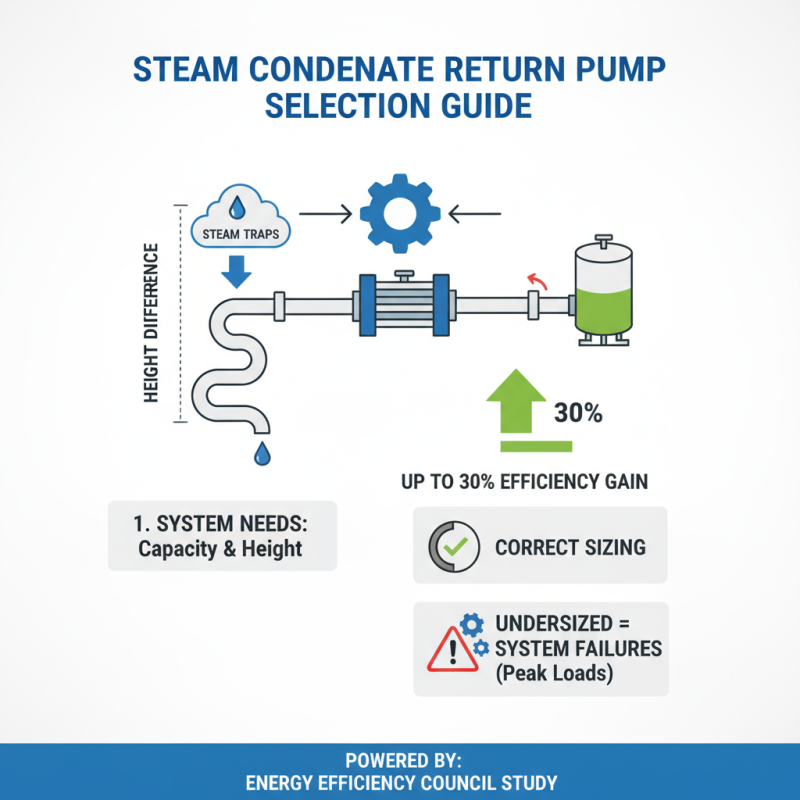

Choosing the right pump requires understanding your system's needs. Factors include flow rate, temperature, and pressure. Each system is unique. What works for one may not suit another. Miscalculating these parameters can lead to problems. An undersized pump won't handle the workload. Conversely, an oversized pump can lead to energy waste and increased maintenance costs.

The material of the pump is also important. Materials must resist corrosion and withstand high temperatures. Regular maintenance is necessary to ensure longevity. You might overlook this. Sometimes, pumps fail due to neglect. It's a reminder that every detail matters for optimal performance.

Key Considerations for Selecting a Steam Condensate Return Pump

When selecting a steam condensate return pump, understanding your system's needs is crucial. Consider factors like the pump's capacity and the height difference between the steam traps and the pump. A study by the Energy Efficiency Council reveals that correct pump sizing increases efficiency by up to 30%. If pumps are underestimated, they may not handle peak loads, leading to system failures.

Tip: Evaluate the heat load during peak operation. This evaluation helps determine the correct pump size. Additionally, assess the temperature and pressure of the steam condensate to prevent equipment failure.

Another critical aspect is the materials used in the pump's construction. Corrosion resistance plays a significant role, especially in high-temperature conditions. According to industry reports, 40% of pump failures are due to material degradation. Regularly inspect materials to ensure they perform as expected.

Tip: Implement a routine maintenance schedule. This can extend the life of the pump and maintain operational efficiency. Remember, a neglected system results in costly downtimes and repairs. Understanding your unique requirements ensures better investment in a steam condensate return pump.

Types of Steam Condensate Return Pumps and Their Applications

Choosing the right steam condensate return pump is crucial. Various pump types cater to different applications. Each type has unique features impacting efficiency and reliability.

Positive displacement pumps are common. They provide consistent flow rates across varying pressures. These pumps excel in low-capacity systems, maximizing energy recovery. According to industry reports, they can achieve up to 90% efficiency. However, they might struggle with high temperature fluctuations, causing operational challenges.

On the other hand, centrifugal pumps handle larger volumes effectively. They are ideal for high-capacity systems. These pumps can manage varying loads reliably. Yet, they may require more maintenance to prevent issues. A study shows that improper installation can reduce their efficiency significantly. This needs attention when integrating them into existing systems.

In summary, understanding each pump's applications is vital. Selecting the wrong type can lead to unnecessary costs and inefficiencies. Balancing performance with the system's needs is essential for optimal operation.

Assessing System Requirements and Pump Specifications

Choosing the right steam condensate return pump involves understanding your system's needs. Several factors play a role in this decision. Start by assessing the temperature and pressure of your steam. Know the flow rate required for effective operation. Measure the distance from the pump to the condensate return point. This distance affects pump performance.

Consider the material compatibility as well. Ensure the pump's materials can handle the various condensate properties. Stainless steel may be essential for some systems. Pay attention to the pump design, too. A simple design may mean easier maintenance, but it might not handle all situations well. Complex systems can lead to unforeseen challenges, which can be frustrating.

Evaluate the energy efficiency of potential pumps. Higher efficiency saves costs long-term. Yet, this may sometimes lead you to overestimate the pump's capacity. Not all high-efficiency pumps are suitable for every application. Test different options before finalizing your choice. Consider seeking expert advice if unsure. It’s easy to overlook critical details when making a selection, leading to potential issues later on.

Steam Condensate Return Pump Capacity Comparison

This chart compares the capacities of different steam condensate return pumps based on their specifications.

Maintenance and Operating Considerations for Efficient Performance

When selecting a steam condensate return pump, maintenance is often overlooked. An effective maintenance plan can significantly enhance performance. Regular inspections are essential. Check for leaks, unusual noises, and vibrations. These can indicate potential issues. Electrical connections should also be reviewed frequently, ensuring everything functions smoothly.

Operating considerations play a crucial role as well. The pump must match the system’s requirements. Mismatched pumps can lead to inefficiencies. Monitor the temperature and pressure regularly. Adjustments may be necessary to maintain optimal performance. Remember, ignoring these details may result in greater problems down the line.

Streamlining these processes can boost efficiency, but it’s a constant challenge. Strive for a balance between operation and maintenance. A well-maintained pump allows for reliable service and longer lifespan. Yet, even the best setups can face unexpected hurdles. Reflect on your system’s performance and be ready to adapt as needed.

How to Choose the Right Steam Condensate Return Pump for Your System? - Maintenance and Operating Considerations for Efficient Performance

| Criteria | Description | Importance Level |

|---|---|---|

| Pump Capacity | Determine the volume of condensate to be returned. | High |

| Head Requirements | Evaluate the vertical and horizontal distance the water must be pumped. | Medium |

| Fluid Temperature | Consider the temperature of the condensate and ensure the pump materials can withstand it. | High |

| Maintenance Needs | Assess the ease of maintenance and availability of parts. | Medium |

| Operating Environment | Analyze environmental factors such as space, vibration, and noise regulations. | Medium |

| Power Supply | Review the availability of required power supply and electrical specifications. | High |

| Pump Type | Choose between electric, steam, or air-driven pumps based on application needs. | High |

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Understanding Canned Pumps: Types, Applications, and Benefits Explained