Contact Us

2026 How to Choose the Right Industrial Centrifugal Pumps for Your Needs?

Choosing the right industrial centrifugal pumps is crucial for various industries. These pumps play a vital role in processes involving liquids, from chemicals to wastewater. According to a recent market report, the global industrial pump market is expected to reach $66 billion by 2026. Industrial centrifugal pumps account for a significant portion of this growth.

Many organizations still overlook critical factors when selecting these pumps. Efficiency and reliability are paramount. A pump that fails can lead to costly downtime or even safety hazards. Industry experts suggest assessing the application's specific requirements, such as flow rate and fluid viscosity. However, some users may underestimate the importance of pump maintenance. Neglecting this aspect can diminish performance over time.

The choice of industrial centrifugal pumps influences productivity directly. Matching the pump specifications with operational needs is not easy. Many companies struggle with compatibility issues. Misalignment can create inefficiencies. Therefore, understanding the technical details and operational environment is essential. The wrong choice can lead to challenges that require time and resources to address.

Understanding the Basics of Industrial Centrifugal Pumps

Industrial centrifugal pumps are vital in various applications. Understanding their basics helps in making informed decisions. These pumps use rotational energy to move fluids. They are versatile, handling different viscosities and flow rates. However, not all pumps are created equal.

**Tips:** Always assess the fluid type. Some pumps perform poorly with abrasive or corrosive materials. Temperature is also important. Higher temperatures can affect pump efficiency.

Know the pump's performance curves. These graphs display how pumps respond to changes in flow and pressure. Many users overlook them, leading to inefficiencies.

**Tips:** Consider the system's layout. A poorly designed setup can strain any pump. Space constraints may limit your choices, too. Impact on maintenance must be evaluated as well. Think about future needs; flexibility in design could save costs later.

Industrial Centrifugal Pumps Efficiency Comparison

This chart illustrates the efficiency of various types of industrial centrifugal pumps based on flow rate. The data reflects the performance characteristics commonly observed in typical industrial scenarios.

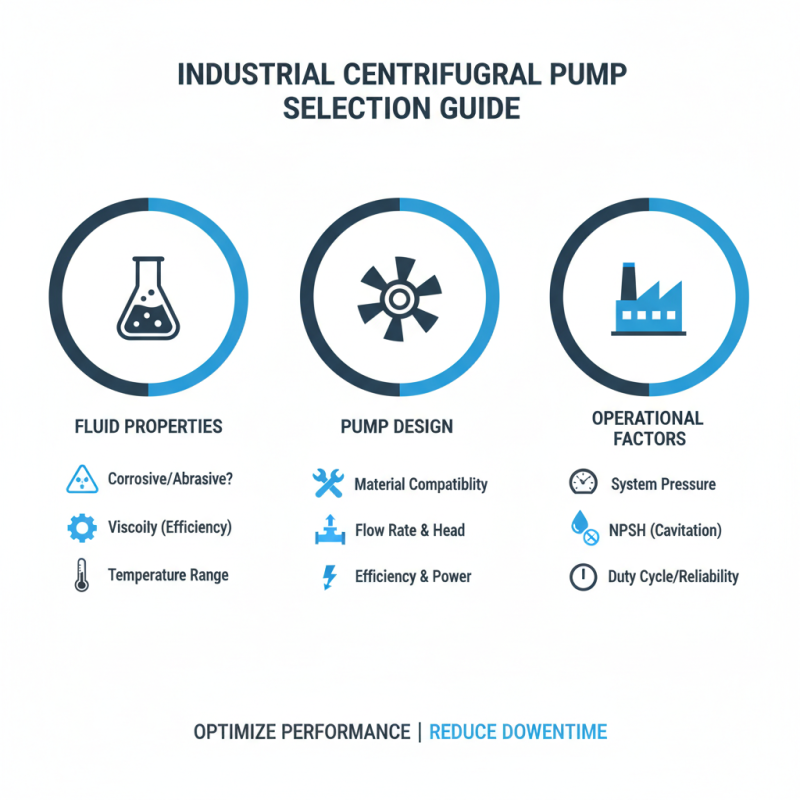

Key Factors to Consider When Selecting Centrifugal Pumps

Choosing the right industrial centrifugal pumps requires careful consideration of several key factors. Start by assessing the fluid properties. Is it corrosive or abrasive? This will affect the materials you should choose. The viscosity impacts the pump's efficiency. Higher viscosity fluids require specific designs. Also, consider the temperature range. Pumps must operate safely within specified limits.

Next, evaluate your system's requirements. Look at the flow rate needed for your processes. It is crucial to choose a pump that meets this demand without excess vibration. Pump performance curves can help determine the right model. Pay attention to Net Positive Suction Head (NPSH) requirements. Insufficient NPSH can lead to cavitation and pump damage over time.

Don't overlook maintenance considerations. Some pumps require more upkeep than others. Extra maintenance can lead to increased costs. Think about the location of the pump in your plant. Accessibility for maintenance is vital. A hard-to-reach pump can cause delays and frustration. Each of these factors will help narrow your options and lead to a better decision for your specific needs.

Assessing Pump Applications and Fluid Properties

When selecting industrial centrifugal pumps, understanding fluid properties is crucial. Different fluids exhibit varying densities, viscosities, and corrosiveness. For instance, a thick sludge requires a pump that efficiently handles high viscosity. Conversely, delicate chemicals may need a pump designed to minimize turbulence. Evaluating the fluid characteristics helps in making informed decisions.

Assessing the application is equally important. Consider the intended use of the pump. Will it be moving water, chemicals, or slurry? Each application demands specific design features. A pulp and paper plant might need robust pumps to handle abrasive materials. An oil and gas facility often requires pumps resistant to corrosion. The environment, temperature, and pressure also play a role in pump selection.

Reflecting on common missteps can save significant time and resources. Many overlook the importance of compatibility between pump materials and the fluid. This oversight can lead to premature wear and costly downtime. Regularly reviewing pump performance against fluid properties is vital. It's essential to adapt as needs change, ensuring optimal efficiency remains a top priority.

2026 How to Choose the Right Industrial Centrifugal Pumps for Your Needs? - Assessing Pump Applications and Fluid Properties

| Application | Fluid Type | Flow Rate (GPM) | Head (Feet) | Viscosity (cP) | Temperature (°F) | Material |

|---|---|---|---|---|---|---|

| Water Treatment | Water | 150 | 50 | 1 | 70 | Stainless Steel |

| Chemical Processing | Acid | 80 | 45 | 5 | 120 | PP |

| Food and Beverage | Syrup | 60 | 30 | 100 | 70 | 316 Stainless Steel |

| Petroleum | Crude Oil | 200 | 60 | 50 | 100 | Cast Iron |

| Pharmaceutical | Chemical Solution | 50 | 40 | 10 | 80 | Hastelloy |

Evaluating Efficiency, Performance, and Reliability Standards

When selecting industrial centrifugal pumps, efficiency, performance, and reliability are key factors.

Efficiency determines operational costs.

A pump that consumes less energy can save significant money over time. Look for energy efficiency ratings during your research.

A pump’s efficiency can influence overall production costs.

Performance is equally critical. Consider factors like flow rate and head pressure for your specific applications.

Proper sizing ensures optimal performance. If not sized correctly, it could lead to problems, like decreased productivity and increased wear.

Tips to remember: Always assess your system requirements first. Know your fluid specifications,

including viscosity and temperature. These details impact pump performance significantly. Test multiple options with real-world applications, if possible.

Checking reliability standards is vital too. Pumps should meet industry standards to ensure durability over time.

Maintenance and Support Options for Your Chosen Pump

When selecting an industrial centrifugal pump, maintenance and support are crucial factors. According to industry reports, effective maintenance can increase pump lifespan by 20-50%. Regular inspections help identify potential issues early, reducing downtime. Thus, it's essential to consider service agreements when making your choice. Having a reliable partner for maintenance can ensure your pump operates efficiently.

Additionally, understanding the availability of spare parts is vital. Delayed repairs can lead to significant operational losses. A study revealed that 30% of companies faced production halts due to unavailability of replacement components. Checking the supply chain for parts is necessary, especially for older models.

Choosing a pump without considering support options can be a misstep. It's not just about the initial purchase. Inadequate support can translate to ongoing headaches. The right maintenance regime can save costs in the long run. Focus on the service life, downtime reduction, and responsive support. Making an informed decision means assessing all aspects of pump operation, including maintenance.

Related Posts

-

Top 10 Multistage Centrifugal Pump Benefits and Applications You Should Know

-

7 Essential Tips for Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

How to Choose the Right Turbine Pump for Your Needs: A Comprehensive Guide

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Why Are Industrial Condensate Pumps Essential for Efficient Water Management?