Contact Us

How to Choose the Right Boiler Condensate Pump for Your Needs?

Choosing the right boiler condensate pump can greatly impact your heating system's efficiency. A suitable pump helps manage excess water, ensuring that your boiler runs smoothly. An improper choice can lead to system failures and costly repairs.

When selecting a boiler condensate pump, consider various factors. The size and capacity of the pump are crucial to match the demands of your boiler. Look at the materials used too. Some pumps are built for harsher conditions than others. Reliability should never be overlooked. A poorly functioning pump can disrupt operations and cause damage.

Pay attention to the installation and maintenance needs as well. Complex systems may require more frequent checks. Don't forget to evaluate the noise level. A noisy pump can be bothersome. Overall, take your time to reflect on these choices. It’s essential for long-term performance and cost-effectiveness.

Understanding Boiler Condensate Pumps and Their Functionality

Boiler condensate pumps play a crucial role in heating systems. They are designed to remove condensate, the byproduct of steam heating. As steam cools, it turns back into water, which needs to be pumped away. If this condensate is not handled properly, it can lead to water damage and inefficiencies.

Understanding how these pumps work is essential. They typically operate automatically, responding to the water level in a condensate return tank. Some models have alarms for malfunction. Choosing the right size is important. A small pump may struggle with heavy flows. On the other hand, a large one might waste energy.

When selecting a pump, consider the system's capacity and the height it needs to pump water. Noise levels can also vary. Some users may find certain models too loud for their space. Reflecting on the pump's location is key. Proper installation can help avoid issues later on. Not every choice will be perfect, and that's okay. Regular maintenance is essential to keep everything running smoothly.

Key Factors to Consider When Selecting a Boiler Condensate Pump

When selecting a boiler condensate pump, several key factors come into play. The pump's capacity is crucial. It must handle the volume of condensate produced without issues. Typically, a higher capacity pump can efficiently deal with unexpected surges. However, oversizing can lead to inefficiencies. It's essential to match the pump size to your specific system needs.

Another critical consideration is the materials used in the pump. Different environments may require specific materials to prevent corrosion. If the condensate is acidic or contains harmful substances, a durable material is essential. Plastic or stainless steel may be preferable, depending on your context. Additionally, think about the pump's installation location. Accessibility can affect maintenance and operation.

Pay attention to the pump's sound level too. Some models can be quite noisy, disrupting your work environment. Noise reduction features can be beneficial in residential settings. It’s also wise to look at energy efficiency ratings. An efficient pump saves energy. But some models claim efficiency without evidence. Research is paramount before making a decision. Ultimately, careful evaluation of these factors ensures the right choice.

How to Choose the Right Boiler Condensate Pump for Your Needs?

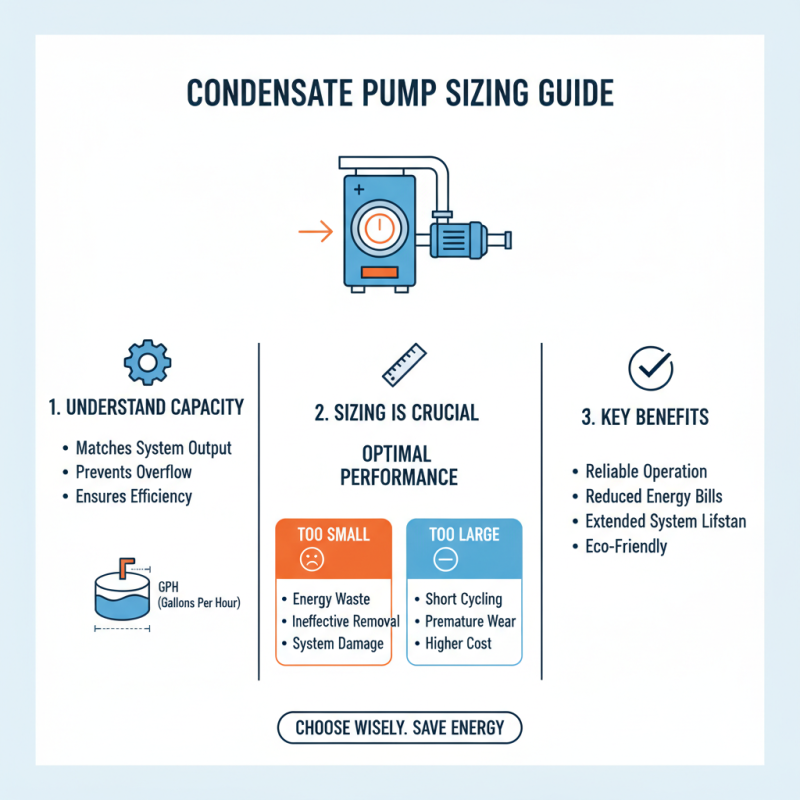

Evaluating Pump Capacity: Sizing Your Condensate Pump for Efficiency

Choosing the right condensate pump starts with understanding pump capacity. This ensures efficiency in your heating system. Sizing a pump is crucial for optimal performance. An incorrectly sized pump can lead to issues. It might waste energy or fail to remove condensate effectively.

To size your condensate pump, assess your system's requirements carefully. Calculate the expected condensate volume. This may vary based on steam usage and system design. A larger pump isn't always better. It can lead to energy inefficiencies. Conversely, a small pump may struggle, causing backups or flooding.

Consider your specific application. Are you dealing with a high-demand environment? Or is it a smaller system? Reflect on your past experiences. Have you faced issues with pump failures or inefficiencies? Addressing these concerns now can save you time and money in the long run. Always remember: the right fit enhances performance and longevity.

Material Compatibility and Durability in Boiler Condensate Pumps

When selecting a boiler condensate pump, material compatibility is crucial. Different systems require specific materials to endure high temperatures and acidic conditions. Common materials include stainless steel and thermoplastics. A report from the International Journal of Materials Science highlights that stainless steel is more resistant to corrosion compared to other materials.

Durability can be a challenge. Pumps experience constant pressure and must withstand thermal cycling. According to a study by the American Society of Mechanical Engineers, improperly selected materials can lead to pump failures within just a few months. It’s vital to assess the environment the pump will operate in.

In some cases, the wrong choice may lead to expensive repairs. For example, using a less durable plastic in high-heat environments accelerates wear. A preventive approach is to consult experts. They can help ensure that you choose materials that align with your operating conditions. It’s important to think through your unique needs and challenges. This can prevent future headaches and maximize the lifespan of your equipment.

How to Choose the Right Boiler Condensate Pump for Your Needs?

| Pump Feature | Description | Material Compatibility | Durability Rating | Typical Applications |

|---|---|---|---|---|

| Motor Type | Standard electric motor or energy-efficient options | Aluminum or stainless steel components | High (over 10,000 hours) | Residential Heating |

| Pump Capacity | Lift and flow rates suitable for various systems | Compatible with condensate and water | Medium (5,000 to 10,000 hours) | Industrial usage |

| Connection Type | Standard flanges or threaded connections | Plastic or PVC fittings | Low (under 5,000 hours) | Light Commercial |

| Impeller Design | Single stage or multi-stage options | Nylon or stainless steel | High (over 10,000 hours) | High-efficiency systems |

| Control Options | Manual or automatic controls available | Compatible with various control systems | Medium to High | Commercial buildings |

Energy Efficiency Ratings: Choosing a Cost-Effective Pump Solution

When selecting a boiler condensate pump, energy efficiency should be a top priority. A pump with high efficiency ratings can lead to significant cost savings. Look for models that display energy efficiency indicators such as the Energy Star label or similar certifications. These ratings often reflect how effectively a pump converts energy into useful work, which can save you money on utility bills in the long run.

However, not all pumps are created equal. Some may promote energy efficiency but may lack durability. Consider the pump’s materials and construction. A well-built pump resists wear and tear, even when working hard. Think about the long-term implications of your choice. A cheaper option might tempt you but could lead to higher costs over time due to repairs or replacements.

Pay attention to the specific needs of your system. The size and type of the boiler matter. An oversized pump may lead to energy wastage. On the flip side, an undersized pump might struggle to keep up, reducing overall efficiency. Make sure to match your pump to your system’s demands. Finding the right balance can be challenging but is essential for achieving optimal performance and efficiency.

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

2026 How to Choose the Right Commercial Condensate Pump for Your Needs?

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems