Contact Us

2026 How to Choose the Right Commercial Condensate Pump for Your Needs?

Choosing the right commercial condensate pump is crucial for efficiency. With numerous options on the market, it can be overwhelming. According to industry expert John Smith, “The right pump can save energy and reduce downtime.” This highlights the importance of making an informed choice.

Evaluating your specific needs is vital. Consider factors like capacity, height, and installation space. These details affect performance significantly. Many users overlook these aspects and regret their decisions. A poorly chosen commercial condensate pump can lead to inefficiencies.

Additionally, compatibility with existing systems matters. This requires research and potential consultations. Some pumps may not fit well with your current setup. Don't rush. Take time to assess your requirements. A thoughtful approach can lead to long-term savings and reliability.

Understanding Commercial Condensate Pumps: A Basic Overview

Commercial condensate pumps play a vital role in HVAC systems. They help remove excess water produced during cooling and heating processes. Understanding their function is essential for effective installation and maintenance.

These pumps are designed to handle condensate, which can be corrosive. Not all pumps are created equal, and selecting the right one can be challenging. Factors to consider include capacity, head height, and power source. A higher capacity pump may seem better, but it could lead to unnecessary energy consumption.

Choosing the wrong pump can result in leaks or failures. This can be costly in terms of repairs and downtime. It’s crucial to assess your specific needs thoroughly. Each application may require different specifications. Reflect on how much water will be produced and how far it must be lifted. Balancing your requirements with pump performance can seem daunting, but it's necessary for efficient operation.

Understanding Commercial Condensate Pumps: A Basic Overview

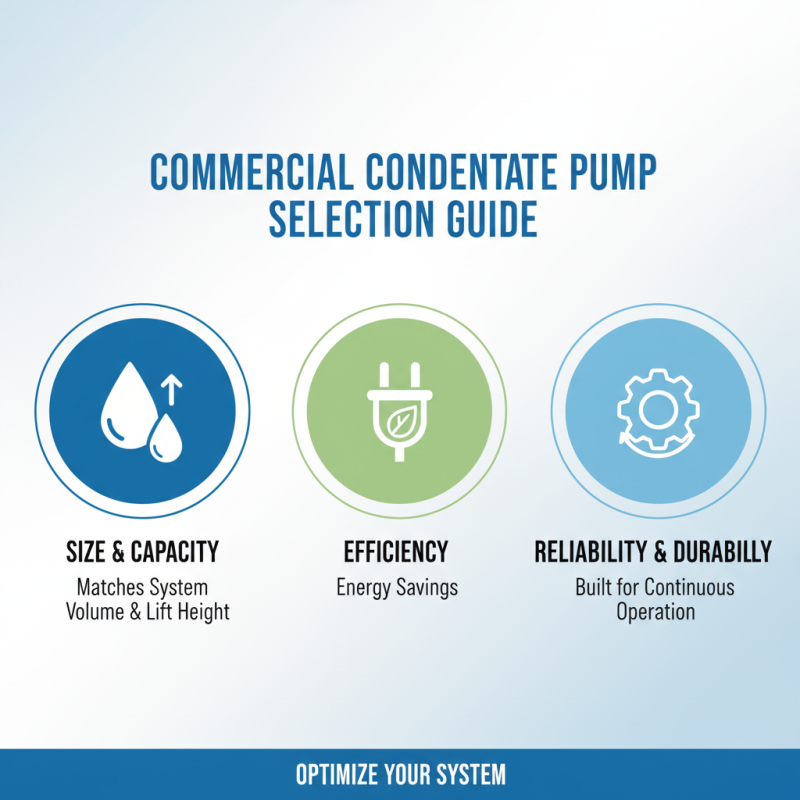

Key Features to Consider When Selecting a Commercial Condensate Pump

When selecting a commercial condensate pump, several key features should guide your decision. Size and capacity are vital. Choose a pump that can handle your system's volume. Consider the height the pump needs to lift condensate. Too small of a pump may create issues. Efficiency is another critical factor. Look for models that promise energy savings over time.

Durability also plays a significant role. Pumps operate in tough environments. Corrosion resistance is essential. Materials like stainless steel often last longer. Noise levels might not seem important, but they can impact your workspace. Some pumps are surprisingly loud.

Serviceability is often overlooked. Verify how easy it is to maintain the pump. Easy access can save time and reduce long-term costs. Researching reviews and feedback is beneficial. Checking common complaints can help avoid pitfalls. Each feature plays a part in overall performance. While one pump may excel in some areas, it may fall short in others.

Evaluating Pump Capacity and Size for Your Specific Applications

Choosing the right commercial condensate pump requires careful evaluation. Pump capacity is crucial for efficiency. You'll want to assess the specific needs of your application. Consider the volume of condensate produced. Too small a pump can lead to overflow. On the other hand, an oversized pump wastes energy.

Size matters, too. The pump should fit within your existing setup. Space constraints can limit your options. If the pump is too large, it may not only fit poorly but also create maintenance challenges. A properly sized pump operates quietly and efficiently.

It’s essential to reflect on the long-term implications of your choice. Will it handle peak demand? Is it easy to service? Sometimes, what seems perfect initially can reveal weaknesses over time. Gather feedback from end-users. Their insights can highlight potential shortcomings. A well-chosen pump boosts performance, but a rushed decision could lead to regrets.

Assessing Energy Efficiency and Environmental Impact of Pumps

Choosing the right commercial condensate pump involves understanding energy efficiency and environmental impact. Many pumps operate on electricity. Their energy consumption varies widely. When selecting a pump, look for models that consume less energy. They often have variable speed drives. Such technology adjusts the pump's performance to match the actual load.

Environmental impact is equally important. A pump that uses less energy reduces carbon emissions. Some pumps offer eco-friendly features, like low noise levels and reduced heat production. However, the materials used in pumps can also affect the environment. Check if the pump components are recyclable or made from sustainable resources. Sometimes, cheaper options harm the ecosystem.

It’s not always easy to measure a pump's efficiency. Manufacturers may provide ratings, but real-world performance can differ. Collecting data on actual energy use helps. Regular maintenance is crucial too. A poorly maintained pump uses more energy and may have more environmental consequences. Reflection on these aspects ensures better choices for both efficiency and sustainability.

Installation and Maintenance Tips for Optimal Pump Performance

When considering the installation of a commercial condensate pump, proper placement is crucial. Position the pump near the source for efficiency. Ensure it is level to avoid vibration and noise issues. Regularly check the surrounding environment for any obstructions. This will help in maintaining optimal performance.

Maintenance is key to extending the life of your pump. Inspect it regularly for any signs of wear or blockages. Clean the pump and its components frequently. A simple cleaning can prevent costly repairs later. Be cautious with debris accumulation. It can significantly impact functionality.

Don't overlook the importance of proper wiring and connections. Poor electrical connections can lead to pump failure. Always verify that the power supply matches the pump requirements. Consider a backup system for added security. This reflection can save you from unexpected downtime.

2026 How to Choose the Right Commercial Condensate Pump for Your Needs? - Installation and Maintenance Tips for Optimal Pump Performance

| Pump Type | Flow Rate (GPH) | Max Head (Feet) | Power Requirement (HP) | Recommended Application |

|---|---|---|---|---|

| Standard Condensate Pump | 1200 | 15 | 1/3 | HVAC Systems |

| High-Efficiency Pump | 2000 | 20 | 1/2 | Commercial Boilers |

| Submersible Condensate Pump | 1500 | 25 | 1/4 | Industrial Applications |

| Vacuum Pump | 800 | 10 | 1/3 | Pharmaceutical Industry |

| Automatic Condensate Pump | 1800 | 30 | 1/2 | Commercial Kitchens |

Related Posts

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

Why is a Steam Condensate Return Pump Essential for Energy Efficiency?

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

2025 Top 10 Boiler Feed Tanks for Efficient Water Management

-

2025 How to Choose the Right Propane Transfer Pump for Your Needs

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems