Contact Us

How to Choose the Right Turbine Pump for Your Needs: A Comprehensive Guide

Choosing the right turbine pump is essential for various industrial applications, from agriculture to municipal water supply, as these pumps are designed to efficiently move fluids through a system. According to a report by the Global Market Insights, the turbine pump market is expected to grow at a CAGR of over 4.5% through 2025, driven by advancements in technology and increasing demand for energy-efficient solutions. Turbine pumps are favored for their ability to handle high-pressure conditions while maintaining a compact design, making them suitable for both surface and deep-well pumping systems.

When selecting a turbine pump, it is crucial to consider the specific application requirements, such as flow rate, total dynamic head, and the type of fluid being pumped. Industry experts recommend conducting a thorough analysis of these factors to ensure optimal performance and longevity of the pump. Additionally, a consistent focus on maintenance and operating conditions can significantly impact the efficiency and reliability of turbine pumps. Understanding these variables will empower decision-makers to choose the right turbine pump that not only meets current operational needs but also adapts to future demands in an evolving industrial landscape.

Understanding Turbine Pumps: Types and Applications in Industry

Turbine pumps have become indispensable in various industrial applications due to their ability to handle large volumes of fluid efficiently. These pumps operate based on the principle of converting kinetic energy into hydraulic energy, making them a preferred choice for projects requiring high flow rates, such as irrigation, municipal water supply, and chemical processing. According to a report by the Global Market Insights, the turbine pump market is projected to reach $10 billion by 2026, driven by the growing demand for energy-efficient pumping solutions.

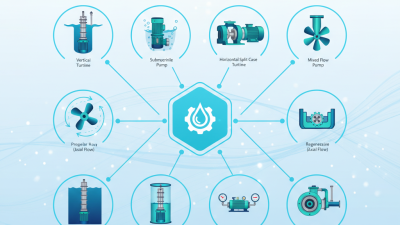

There are several types of turbine pumps, including vertical turbine pumps, submersible turbine pumps, and horizontal turbine pumps, each suited for specific applications. Vertical turbine pumps are typically used for deep well extraction, while submersible turbine pumps are ideal for underwater operations, such as borehole pumping applications. Horizontal turbine pumps, on the other hand, are often employed for surface water applications. Understanding the specific fluid characteristics and application requirements is crucial for selecting the most suitable turbine pump.

Tips: When choosing a turbine pump, consider factors such as the required flow rate, the total dynamic head, and the fluid's specific properties, including viscosity and temperature. Furthermore, it is advisable to consult with an expert to ensure that installation and maintenance practices align with industry standards for optimal performance and longevity of the pump.

Key Factors to Consider When Selecting a Turbine Pump

When selecting the right turbine pump for your specific needs, there are several key factors to consider that can significantly impact efficiency and performance. Firstly, understanding the application requirements is crucial. This encompasses factors such as flow rate, head height, and the type of fluid being pumped. According to the Hydraulic Institute, selecting a pump that matches the system’s hydraulic characteristics is essential. For instance, a mismatch can lead to energy losses ranging from 10-30%, affecting overall operational costs.

Another important consideration is material compatibility. Turbine pumps are commonly used in various industries, including agriculture, oil and gas, and municipal water services. The fluid's chemical composition can dictate the materials used in the pump construction. Data from the American Society of Mechanical Engineers (ASME) indicates that corrosion can lead to severe damage, accounting for about $276 billion annually in the U.S. alone. Therefore, choosing materials that can withstand specific chemical interactions is vital to prolonging the pump's life and minimizing maintenance costs.

Finally, the pump’s efficiency and energy consumption should not be overlooked. According to the U.S. Department of Energy, optimizing pump efficiency can reduce energy costs by up to 20%. Look for pumps designed with advanced hydraulic designs and variable speed capabilities to ensure they operate within the best efficiency point, thereby meeting not just performance benchmarks but also economic and environmental goals.

Performance Metrics: Flow Rate, Head, and Efficiency Ratings

When selecting the right turbine pump, understanding performance metrics is vital to make an informed choice. Flow rate, measured in gallons per minute (GPM) or liters per second (L/s), determines how quickly a pump can move water and significantly influences its suitability for specific applications.

A higher flow rate is essential for systems that require large volumes of water quickly, such as irrigation or industrial processes, while lower flow rates may suffice for residential or smaller operations.

Equally important is the head, which refers to the height to which the pump can raise the water, typically measured in feet or meters. This metric is crucial for applications where fluid needs to be transported over significant vertical distances. If the required head exceeds the pump’s capability, it may lead to inefficient operation or even pump failure.

Lastly, efficiency ratings provide insight into how effectively the pump converts mechanical power into hydraulic energy. A more efficient pump will not only reduce operational costs but also minimize energy consumption, leading to a more sustainable operation over time. Understanding these key performance metrics will enable users to select a turbine pump that aligns with their specific requirements, ensuring optimal performance and reliability.

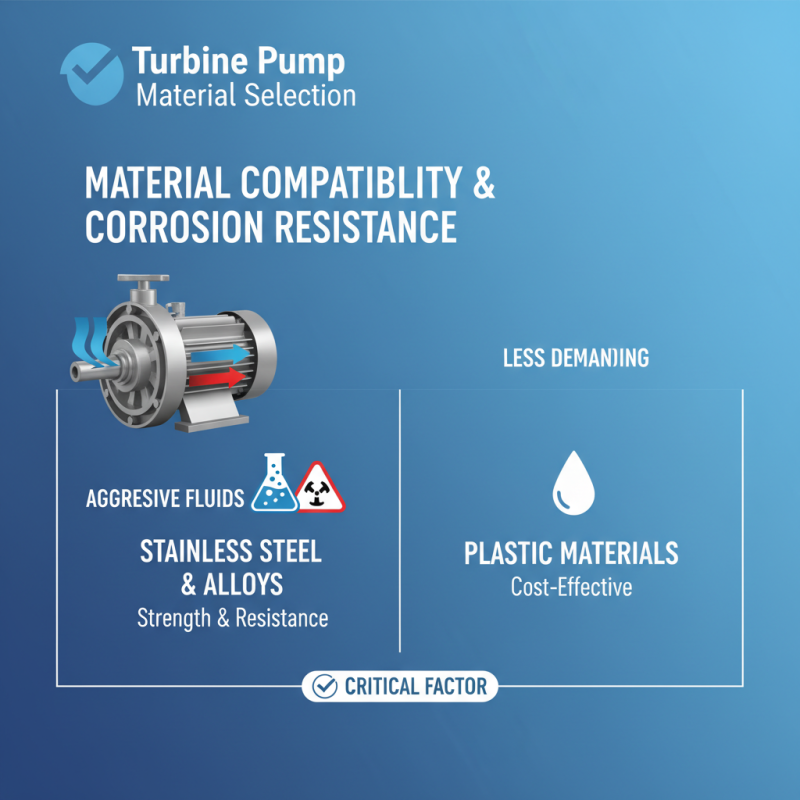

Material Compatibility and Corrosion Resistance in Turbine Pump Selection

When selecting a turbine pump, one of the most critical factors to consider is material compatibility and corrosion resistance. Different materials exhibit varying levels of resistance to specific chemicals and environmental conditions. For instance, if your application involves handling aggressive fluids or operates in a corrosive environment, it is essential to choose a pump constructed with materials that can withstand such challenges. Stainless steel and various alloys often provide a good balance between strength and resistance, while plastic materials may be suitable for less demanding applications.

Tips: Always review the compatibility of the pump materials with the fluids being pumped. Conducting a compatibility test with small samples can help identify potential issues before making a significant investment. Additionally, consider environmental factors such as temperature and pressure, which can also impact material integrity over time.

Moreover, it's advisable to consult with manufacturer specifications and guidelines regarding corrosion resistance. Some manufacturers provide detailed data on the performance of their pump materials under various conditions, which can greatly aid in your decision-making process. Ensuring that the selected turbine pump can withstand the corrosive elements present during its operation will not only enhance its efficiency but also prolong its lifespan, leading to reduced maintenance costs in the long run.

Maintenance and Longevity: Ensuring Optimal Performance of Turbine Pumps

Effective maintenance of turbine pumps is crucial for ensuring their longevity and optimal performance. According to the Department of Energy, properly maintained pumps can operate up to 90% more efficiently compared to those that are neglected. Regular inspections, including checking for signs of wear and tear, verifying alignment, and evaluating the lubrication system, are essential. This proactive approach can prevent costly breakdowns and extend the operational lifespan of the equipment.

Furthermore, the Hydraulic Institute notes that implementing a routine maintenance schedule can reduce the risk of unexpected failure by 50%. It is recommended to monitor performance indicators such as flow rate, pressure levels, and energy consumption, as deviations from normal operating parameters can signal underlying issues. Additionally, regular cleaning of components and replacement of worn parts not only ensures optimal functionality but also contributes to energy savings, further enhancing the cost-effectiveness of turbine pump operations over time. With a strategic focus on maintenance, operators can maximize the reliability and efficiency of their turbine pumps.

Performance Comparison of Turbine Pumps

This bar chart illustrates the performance comparison of five different turbine pumps based on their flow rate in gallons per minute (GPM) and efficiency percentage. Selecting the right turbine pump involves analyzing these metrics to ensure optimal performance and longevity.

Related Posts

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

10 Essential Tips for Choosing the Right Pressure Pumps for Your Needs

-

Top 10 Turbine Pump Types for Efficient Water Management Systems

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025