Contact Us

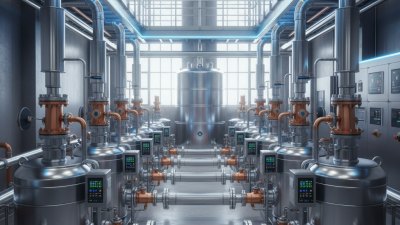

10 Essential Tips for Choosing the Right Pressure Pumps for Your Needs

When selecting the appropriate pressure pumps for your applications, understanding the specific requirements and functionalities is crucial. According to a recent market analysis by Grand View Research, the global pressure pump market is expected to reach USD 20.7 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.5%. This growth reflects the increasing demand for efficient water management systems across various industries, including agriculture, manufacturing, and municipal water supply.

Industry expert Dr. Emily Carter, a prominent figure in pump technology, emphasizes the importance of making informed choices in this field. She states, "Selecting the right pressure pump not only enhances operational efficiency but also significantly reduces energy consumption and operational costs." Therefore, understanding the diverse range of pressure pumps available in the market and their specific applications can guide you toward making the optimal selection for your needs. This article explores ten essential tips to help you navigate the complexities of choosing the right pressure pumps tailored to your requirements, ensuring that your investment delivers the best possible performance and durability.

Understanding Different Types of Pressure Pumps: A Comprehensive Overview

When it comes to selecting the right pressure pump, it's crucial to understand the various types available on the market. Pressure pumps generally fall into several categories, including centrifugal, diaphragm, and positive displacement pumps. Centrifugal pumps are primarily used for high-flow applications where the fluid is moved through an impeller. They are known for their efficiency and are ideal for continuous operation, making them a popular choice in agricultural and industrial settings.

On the other hand, diaphragm pumps excel in handling viscous fluids and offer a bit more versatility due to their ability to run dry without sustaining damage. These pumps utilize a flexible diaphragm to create a pumping action, which is particularly beneficial in chemical and wastewater applications. Lastly, positive displacement pumps, including gear and screw pumps, are appropriate when precise flow control is needed, as they ensure a uniform output regardless of pressure variations. Understanding these types can significantly influence your decision, ensuring you choose a pump that meets your specific needs effectively.

Evaluating Performance Metrics: How PSI and GPM Affect Your Pump Selection

When selecting a pressure pump, understanding the performance metrics—specifically PSI (pounds per square inch) and GPM (gallons per minute)—is crucial. PSI indicates the pump's ability to generate pressure, which determines how far and forcefully the liquid can be delivered. For instance, residential pressure washing typically requires a pump with a PSI rating between 1300 and 3000. According to the American Society of Plumbing Engineers, pumps within this range effectively handle most household tasks, while industrial applications may demand higher PSI values exceeding 5000 for optimal performance in cleaning or surface preparation.

GPM, on the other hand, measures the flow rate of the pump, dictating how quickly water is delivered. A balance between PSI and GPM is essential; for example, a pump with high PSI but low GPM may result in insufficient water delivery for extensive cleaning jobs. An industry report by the Hydraulic Institute suggests that the ideal pressure pump should boast a GPM of at least 2.5 for effective cleaning, particularly for applications like agricultural spraying or car washes. Hence, when assessing pumps for specific tasks, customers should carefully evaluate both PSI and GPM to ensure they choose a model that meets their performance demands.

Assessing Efficiency Ratings: The Importance of Energy Consumption in Pump Choices

When selecting pressure pumps, evaluating efficiency ratings is crucial, as energy consumption significantly impacts both operational costs and environmental sustainability. According to the U.S. Department of Energy, over 20% of industrial electricity consumption is attributed to motor-driven systems, which include pumps. Choosing pumps with high-efficiency designs can lead to energy savings of up to 30%, translating into substantial cost reductions over time. Investing in energy-efficient models not only benefits the bottom line but contributes to a lower carbon footprint, aligning with corporate sustainability goals.

Moreover, the performance of pressure pumps should be assessed through their efficiency ratings, often represented as the pump's Energy Efficiency Index (EEI). A 2021 study published by the Hydraulic Institute indicates that pumps with an EEI rating above 0.6 are considered energy-efficient, reducing unnecessary energy waste. By prioritizing pumps that meet or exceed these standards, businesses can enhance their operational efficiency while ensuring compliance with increasingly stringent environmental regulations. In a market where energy costs continue to rise, making informed choices about pressure pumps based on their efficiency ratings is indispensable for long-term financial and ecological health.

Energy Efficiency Ratings of Various Pressure Pumps

Key Features to Consider: Materials, Sizes, and Application Suitability

When selecting the right pressure pump, it’s crucial to consider key features such as materials, sizes, and application suitability. The materials of the pump not only determine its durability but also its compatibility with the fluids it will handle. For example, stainless steel pumps are ideal for corrosive liquids, while thermoplastic options may work well for less aggressive substances. Ensuring that the pump’s materials match the requirements of your specific application can significantly extend its lifespan and reduce maintenance costs.

Size is another vital factor in choosing a pressure pump. The pump must be appropriately sized to handle the required flow rate and pressure for your application. Under-sized pumps can lead to inefficiency and increased wear, while oversized pumps may waste energy and result in unnecessary operational expenses. Take into account the space constraints of your installation as well, ensuring that the pump fits comfortably within the designated area without compromising performance.

Finally, application suitability cannot be overlooked. Different pumps are designed for various tasks, from irrigation and industrial use to residential water supply. Assess the primary function of the pump and consider factors such as the required pressure range, continuous vs. intermittent use, and any specific regulations or environmental considerations that might impact your choice. By carefully evaluating these features, you can ensure that your pressure pump meets both your operational needs and your long-term goals.

Matching Pump Specifications with Industry Standards: Ensuring Compliance and Reliability

When selecting a pressure pump, ensuring compliance with industry standards is crucial for both reliability and performance. According to the Hydraulic Institute, about 80% of pump failures stem from incorrect installation or specification mismatches. Thus, understanding pump specifications and how they align with established standards, such as those set by the American National Standards Institute (ANSI), is essential. Pumps must meet requirements for efficiency, safety, and suitability for specific applications, including chemical resistance and environmental compatibility.

Moreover, industry reports emphasize the importance of adhering to standards like ISO 9001, which sets out the criteria for a quality management system. This can significantly reduce operational risks and enhance product life cycle. For instance, a study by the International Pump User's Symposium highlighted that companies using compliant pumps experienced up to 30% lower maintenance costs over five years. By focusing on matching pump specifications with these rigorous standards, businesses not only ensure operational efficiency but also gain trust and credibility in their markets.

Related Posts

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home