Contact Us

10 Essential Tips for Choosing the Right Propane Pump for Your Needs?

Choosing the right propane pump is crucial for efficiency and safety in various applications. According to the Propane Education & Research Council, propane is a widely used fuel source, and selecting the appropriate pump can impact both performance and cost. Industry expert Mark Thompson stated, "An ideal propane pump balances reliability with ease of use while meeting all regulatory standards."

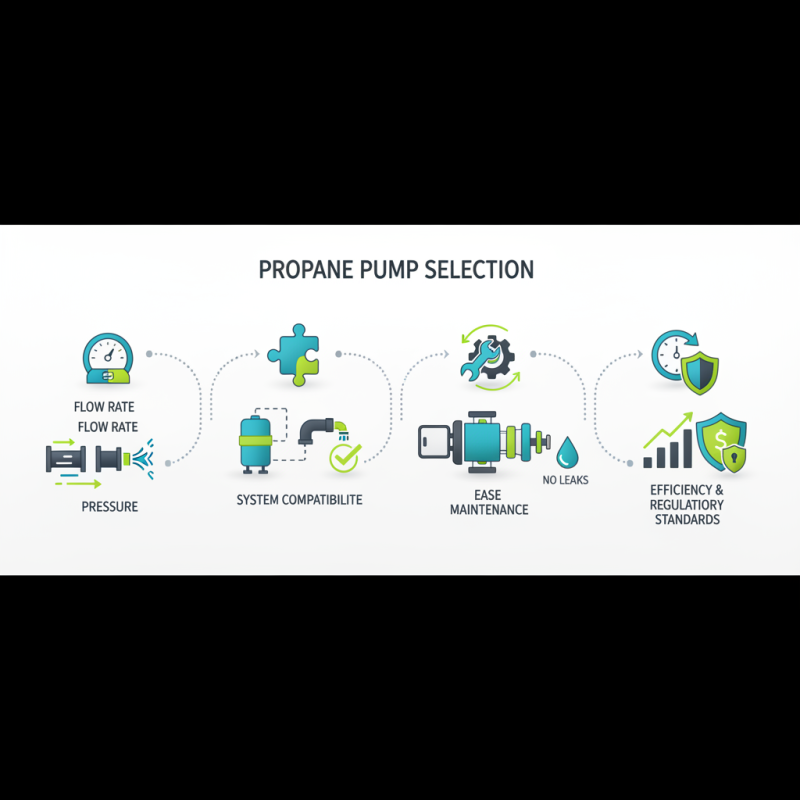

When looking for a propane pump, consider flow rate and pressure. These specifications affect how quickly and effectively the propane is moved. Ensure the pump fits your specific needs; otherwise, you may face operational delays or safety hazards. Many users overlook details like compatibility with existing systems. Every detail matters in this industry, and a small oversight can lead to inefficiencies.

Additionally, maintenance is key. Choosing a propane pump that’s easy to maintain can save time and money. Reports suggest that neglected pumps can lead to leaks, which pose safety risks. While many options exist, the right one should fit seamlessly into your workflow. In choosing a propane pump, take the time to evaluate every aspect to avoid regrets down the line.

Understanding Your Propane Pump Needs and Applications

When selecting a propane pump, understanding your specific needs is crucial. Propane pumps come in various sizes and capacities, essential for different applications. A recent industry report indicated that the most common pump capacity ranges from 5 to 30 GPM (gallons per minute). This range fits well for residential use and small commercial setups. However, larger operations might require pumps that can handle higher volume demands.

Consider where you will use the pump. Mobile applications, such as fueling tanks for vehicles or equipment, may need a hand pump or a portable model. Conversely, fixed installations often do better with stationary pumps. According to industry surveys, 45% of users prefer pumps with electronic metering systems for accuracy. Yet, it’s essential to note that automation can lead to complications if the equipment is not well maintained.

Don't overlook the environmental considerations. It's vital to choose pumps designed for efficiency to minimize emissions. An estimated 20% of propane waste can occur due to leaks in poorly designed systems. Regular checks and updates can mitigate this issue. Each choice you make affects efficiency and environmental impact. Balancing your needs with these factors is a challenge but crucial for the right propane pump selection.

Types of Propane Pumps: Choosing the Right Type for Your Use

When selecting a propane pump, understanding the types available is crucial. There are various designs suited for different tasks. For instance, diaphragm pumps work well for low-volume applications. This type is often quieter and more compact. However, they may not be efficient for high-pressure needs.

Centrifugal pumps, on the other hand, excel in transferring large volumes quickly. They are ideal for industrial uses. Yet, they can be bulkier and require more energy. Consider the power source too. Electric pumps are user-friendly but might limit mobility. Manual pumps offer portability but demand more physical effort.

Choosing the right type involves assessing your specific needs. Think about the environment where the pump will be used. Challenges like space and accessibility can affect your choice. Don't rush the decision; testing a few options might be beneficial. Take time to reflect on your long-term requirements. This can save you from regrets later on.

10 Essential Tips for Choosing the Right Propane Pump for Your Needs

Key Features to Look for in a Propane Pump

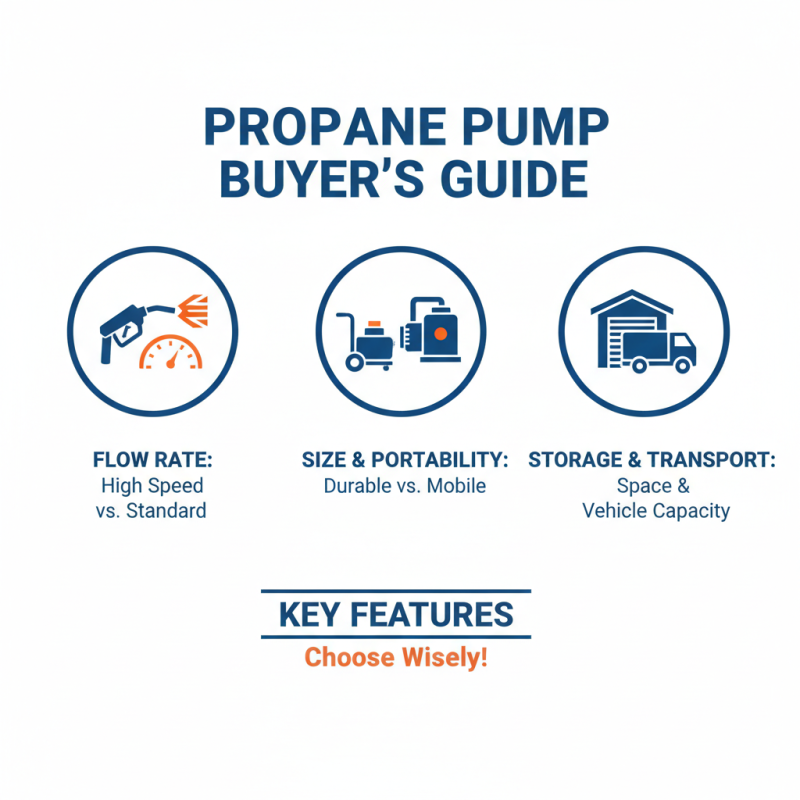

When choosing a propane pump, several key features should be prioritized. The flow rate is vital. It determines how quickly the pump transfers fuel. Consider whether you need high speed or if a standard rate suffices. Pump size and portability also matter. A heavier pump may be more durable but harder to move. Assess your storage space and vehicle capacity.

Another critical aspect is power source. Some pumps run on electricity, while others are gas-powered. Evaluate your available energy sources before making a decision. Durability is crucial, too. Look for a sturdy pump that can withstand outdoor conditions. A pump with a protective casing may last longer.

Don't overlook the safety features. Automatic shut-off valves can prevent accidents during operation. Examine the hose length. Longer hoses provide flexibility but may come with weight. Think about the maintenance requirements. Some pumps need frequent checks, while others are low-maintenance. Defining your specific needs can help guide you in this selection process.

Evaluating Pump Capacity and Flow Rate for Efficiency

When selecting a propane pump, evaluating pump capacity and flow rate is vital. The pump capacity determines how much propane can be delivered in a set timeframe. For instance, a pump rated at 10 gallons per minute can quickly fill larger tanks but may be overkill for smaller needs. Studies suggest that 60% of users fail to match pump capacity with their requirements, leading to inefficiencies.

Flow rate impacts efficiency directly. A higher flow rate reduces pumping time, saving both energy and costs. However, an excessive flow rate can create turbulence, causing vapor lock. The ideal flow rate often falls between 5 to 20 gallons per minute, depending on the application. Data shows that many users overlook these specifics. An operational miscalculation can complicate processes.

It's essential to consider your exact needs before diving into a purchase. Choose a pump that aligns with your capacity and flow requirements. Balancing these aspects helps streamline operations. Missing the mark can lead to wasted time and resources. Many have learned this the hard way, adjusting after experiencing the consequences of poor planning. Determining the right fit requires careful assessment and reflection.

10 Essential Tips for Choosing the Right Propane Pump for Your Needs

| Tip No. | Tip Description | Importance | Recommended Flow Rate (GPM) | Suggested Capacity (Gallons) |

|---|---|---|---|---|

| 1 | Determine your dispensing requirements | High | 5-10 | 100-500 |

| 2 | Assess the viscosity of propane | Medium | 10-15 | 200-800 |

| 3 | Consider pump durability | High | 7-12 | 150-700 |

| 4 | Analyze your budget | Medium | 8-14 | 120-600 |

| 5 | Check compatibility with existing systems | High | 6-11 | 200-300 |

| 6 | Evaluate maintenance and support options | Medium | 9-13 | 180-650 |

| 7 | Look for energy-efficient models | High | 5-10 | 100-500 |

| 8 | Research user reviews | Medium | 7-12 | 150-700 |

| 9 | Ask for professional advice | Medium | 8-15 | 190-800 |

| 10 | Plan for future needs | High | 10-20 | 250-1000 |

Budget Considerations: Finding Quality within Your Price Range

When choosing a propane pump, budget considerations play a critical role. Prices can vary widely, so knowing your limits helps. Start by determining how much you can comfortably spend. Look for pumps that fit within your budget without sacrificing quality. It’s tempting to go for the cheapest option, but this may lead to future expenses due to poor performance or durability.

Evaluate features that align with your needs. Some pumps offer advanced capabilities that may seem essential at first glance. However, ask yourself if you really need them. Simplicity often means reliability. A basic model may serve your purpose just as well. Read reviews and consider user experiences. They can provide insight into what’s worth your money.

Don’t hesitate to explore used options as well. Sometimes, you can find quality equipment at lower prices. But it’s essential to assess their condition thoroughly. Maintenance history can reveal a lot. Additionally, think about the long-term costs associated with each choice. A more expensive pump may save money on repairs down the line. Balancing initial costs with future reliability is key in making a smart investment.

Related Posts

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

How to Choose the Right Liquid Propane Pump for Your Needs

-

Top 10 High Temperature Pump Tips You Need to Know for Efficient Operation

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries