Contact Us

10 Essential Tips for Choosing the Right Impeller Pump?

Choosing the right impeller pump can significantly impact efficiency and performance. According to Dr. Michael Thompson, an industry expert, "Selecting the correct impeller pump is crucial for optimal fluid management." Understanding the nuances of impeller pumps is essential for a wide range of applications.

Impeller pumps are vital in both industrial and domestic setups. An effective selection process involves various factors like fluid type, viscosity, and flow rates. A common oversight is neglecting the pump's material compatibility with the intended liquid.

Engineers often rely on specifications but might miss practical considerations. For example, considering pump maintenance and the expected operational life is as significant as technical parameters. By reflecting on these aspects, one can avoid costly mistakes. Selecting the right impeller pump requires careful thought and industry knowledge to ensure the best outcomes.

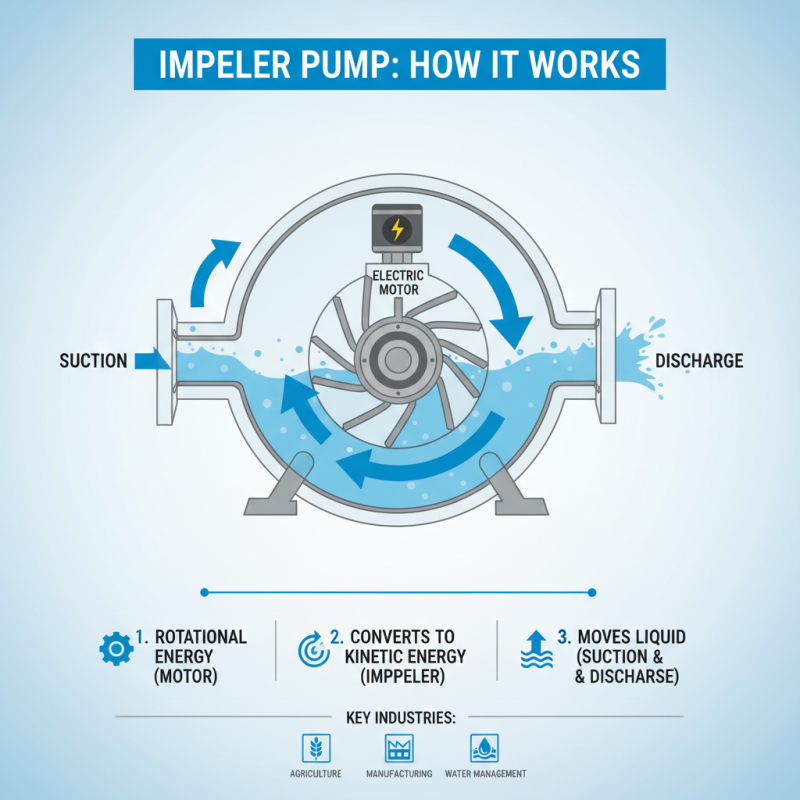

Understanding Impeller Pump Basics and Applications

Impeller pumps are vital in various industries, including agriculture, manufacturing, and water management. Understanding their basic function is crucial. These pumps move liquid by converting rotational energy, often from an electric motor, into kinetic energy. This rotating action creates a vacuum, drawing liquid into the pump and moving it through the discharge pipe.

When selecting the right impeller pump, consider these tips. The pump's capacity should match your flow requirements. If not, it may underperform. Efficiency is another factor; the wrong choice can lead to high operational costs. In a recent industry report, miscalculations in capacity may lead to a 30% increase in energy usage over time. Always assess the specific application. Each type of impeller, including open, semi-open, and closed, serves distinct purposes.

Additionally, think about maintenance needs. Some designs are easier to maintain than others. A report highlighted that neglecting regular maintenance could reduce pump lifespan by 50%. Finding a balance between performance and upkeep is essential. Reflect on these aspects before making your decision.

Key Factors to Consider When Selecting an Impeller Pump

When selecting an impeller pump, certain key factors demand attention. Performance curves are critical. They show how the pump operates across different conditions. Understanding flow rates and pressure requirements is vital. A report from the Hydraulic Institute highlights that more than 30% of pump failures stem from incorrect sizing. Proper matching prevents inefficiencies and prolongs service life.

Material selection also plays a significant role. Impeller pumps can be made of stainless steel, bronze, or plastic. Each material has its advantages and drawbacks. For instance, stainless steel offers corrosion resistance but can be heavier. Conversely, plastic is lightweight but may not handle high temperatures. A study by the American Society of Mechanical Engineers indicates that over 25% of impeller pumps suffer from material degradation due to inappropriate material choice.

Additionally, consider the pump's efficiency rating. Many pumps showcase efficiency levels around 70-85%. However, choosing a model with lower efficiency can lead to increased operational costs. Regular performance assessments are necessary. Monitoring energy usage and flow rates helps identify issues early. These factors are intertwined; even a small miscalculation can result in significant repercussions. Analyzing these aspects thoroughly ensures you choose the right impeller pump for your specific needs.

10 Essential Tips for Choosing the Right Impeller Pump

| Tip Number | Tip Title | Description |

|---|---|---|

| 1 | Understand Your Requirements | Assess the specific needs of your project including flow rate and pressure requirements. |

| 2 | Consider the Fluid Characteristics | Evaluate the type of fluid being pumped (viscosity, corrosiveness, temperature). |

| 3 | Evaluate Pump Materials | Select materials that will withstand the fluid's properties and operational environment. |

| 4 | Assess the Pump's Efficiency | Check the pump's efficiency ratings to ensure operational cost-effectiveness. |

| 5 | Check for Maintenance Requirements | Look at how easy it is to maintain the pump and the availability of service support. |

| 6 | Consider the Noise Level | Take into account noise levels, especially for installations in residential areas. |

| 7 | Review the Manufacturer's Reputation | Research the manufacturer's history and customer feedback on their pumps. |

| 8 | Check for certifications | Ensure the pump meets relevant industry standards and certifications for safety and performance. |

| 9 | Assess the Size and Weight | Consider the physical dimensions and weight for installation space and handling. |

| 10 | Evaluate Cost vs. Benefits | Weigh the initial cost against the long-term benefits and operational savings. |

Comparing Different Types of Impeller Pumps for Specific Needs

When selecting an impeller pump, understanding the types available is crucial. Different applications require different pump designs and performance metrics. For instance, centrifugal pumps are ideal for handling large volumes of fluids with low viscosity. They excel in agricultural irrigation and municipal water systems. According to industry data, centrifugal pumps account for over 80% of the global pump market.

On the other hand, positive displacement pumps are more efficient for high-viscosity fluids. They work well in oil and gas applications, where precision is vital. Consider the operational environment when choosing a pump. Factors like temperature and pressure can significantly impact performance.

Tip: Evaluate the specific needs of your application before deciding. Always check the pump's flow rate and pressure capacity. Ensure that it meets the required standards for your industry. Additionally, be aware of maintenance needs. Some pumps require more frequent servicing, which can lead to increased costs. Balancing efficiency and cost-effectiveness is a key aspect.

Remember, not every pump fits every scenario. Do thorough research. Consult professionals if needed. A wrong choice can lead to operational failures. It’s essential to reflect on the long-term implications of your selection.

Comparison of Different Types of Impeller Pumps

This chart compares the efficiency of various types of impeller pumps based on their maximum flow rate and power consumption. The data provides a guideline for selecting the right pump based on specific needs.

Evaluating Materials and Design Features of Impeller Pumps

When choosing the right impeller pump, evaluating materials and design features is crucial. The material impacts durability and efficiency. Options range from stainless steel to thermoplastics. Each has unique benefits and drawbacks. For example, stainless steel resists corrosion but may be heavy. In contrast, thermoplastics are lightweight but might not withstand high pressures.

Design features also play a key role in pump performance. The shape of the impeller can significantly affect flow rates. A well-designed impeller reduces turbulence and improves efficiency. However, complex designs might complicate maintenance. Look for pumps that balance simplicity with efficiency. Remember, the right choice depends on your specific needs and application.

Sometimes, even with the best intentions, the wrong choice can be made. A pump that seems perfect may not perform as expected. Consider feedback from existing users. They can offer insights that manufacturers often overlook. Always weigh design features against practical experience for a well-rounded decision.

Maintenance Practices for Optimal Performance of Impeller Pumps

Maintaining an impeller pump is crucial for its longevity and efficiency.

Regular inspections can catch small issues before they become significant problems. Check for leaks

and unusual noises during operation. These signs may indicate wear or improper alignment. Make sure to monitor the pump’s

vibration levels. Excessive vibration can result in severe damage over time.

Cleaning the pump regularly helps maintain optimal performance.

Debris can build up and obstruct flow. Remove any accumulated dirt or particles from the strainer and casing.

Ensure all seals and gaskets are intact. Worn seals can lead to leaks and reduced efficiency. Additionally,

lubricate moving parts to prevent friction. This practice enhances

performance and can extend the pump’s lifespan.

Educating staff about proper operational practices is important.

They should understand the correct startup and shutdown procedures. Neglecting these can cause unnecessary stress on the system.

Over time, neglect may lead to costly repairs or replacements. Regular training sessions can improve awareness of best practices.

This proactive approach can make a significant difference.

Related Posts

-

Best High Head Pump Options for Efficient Water Transfer?

-

2026 Top Impeller Pump Innovations and Technologies Insights?

-

How to Choose the Right Turbine Pump for Your Needs: A Comprehensive Guide

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

How to Choose the Right Liquid Propane Pump for Your Needs