Contact Us

Best High Head Pump Options for Efficient Water Transfer?

When it comes to efficient water transfer, selecting the right equipment is vital. A high head pump is essential for moving water easily over long distances or elevations. These pumps excel in applications where pressure is crucial. Whether for irrigation, drainage, or industrial uses, the right high head pump can make a significant difference.

Many options are available in the market today. Each offers unique features and capabilities. Understanding these differences is key to making an informed decision. Some pumps are more suited for specific tasks, while others provide versatility. It is not always clear which model will meet your needs best.

Choosing the right high head pump can be overwhelming. You may face challenges such as budget constraints or varying technical specifications. Sometimes, even the best options may not perform as expected. Careful consideration is necessary. Researching and comparing products will help guide your choice. This journey can be fraught with uncertainties, yet it leads to improved efficiency in water transfer.

Best High Head Pump Types and Their Applications in Water Transfer

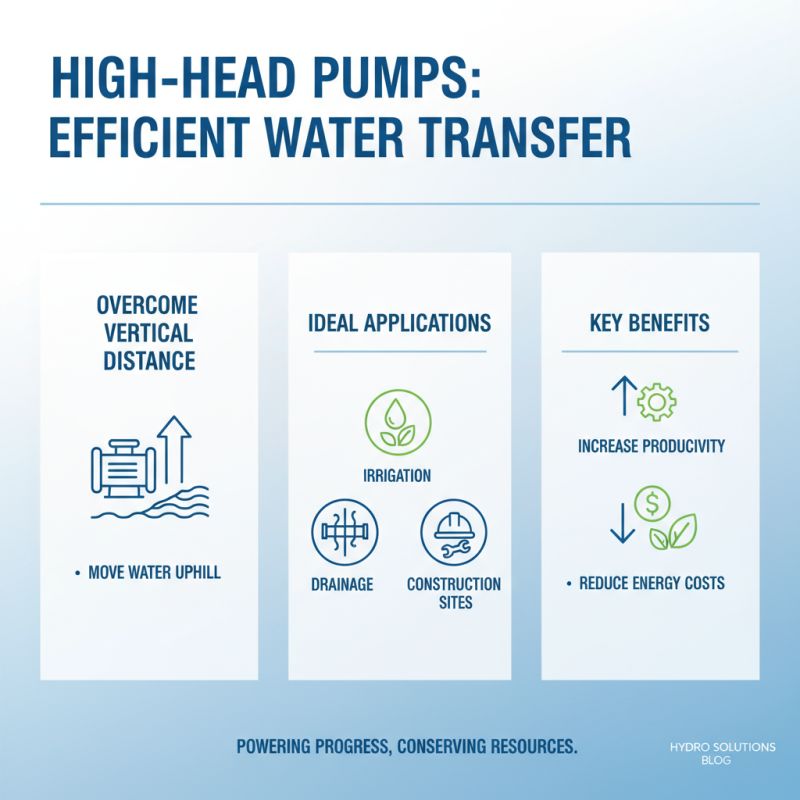

When it comes to high head pumps, they play a crucial role in efficient water transfer. These pumps can overcome significant vertical distances. This capability makes them ideal for applications such as irrigation, drainage, and construction sites. The right pump can increase productivity and reduce energy costs.

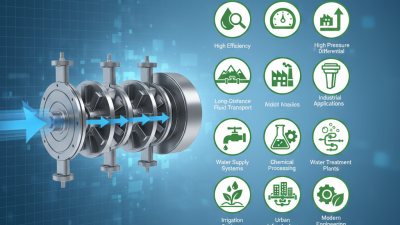

There are various types of high head pumps, each suited for different needs. Centrifugal pumps are commonly used for their efficiency and reliability. Submersible pumps excel in deep well applications, while vertical turbine pumps are beneficial for long-distance water movement. It's essential to choose a pump that fits the specific situation.

However, not all high head pumps are equally effective for every project. A pump that works well in one scenario might struggle in another. A careful assessment of the water source, distance, and elevation is necessary. Consideration of these factors can make a significant difference. A slight oversight might lead to less-than-ideal performance, highlighting the need for thorough planning.

Key Features of High Head Pumps for Efficient Performance

When considering high head pumps, several key features enhance their efficiency. One crucial aspect is the pump's design. Look for models that have a sturdy construction and high-grade materials. This helps minimize wear and tear. A well-designed impeller can boost the flow rate while maintaining pressure. Efficiency improves with the right shape and size, especially in specific applications.

Another essential feature is the motor horsepower. Selecting a pump with adequate power is vital for effective water transfer. An undersized motor may lead to overheating and reduce lifespan. In contrast, an oversized motor can waste energy. It's important to find the right balance based on your needs. Also, consider the pump's ability to handle different fluid types. Some pumps function well with water, while others can accommodate chemicals or slurries.

While high head pumps promise performance, maintenance cannot be overlooked. Regular checks for leaks and blockages prolong the equipment's life. User manuals provide crucial guidance but are often ignored. Ignoring this can lead to significant issues. A well-informed operation not only improves efficiency but also promotes safety. Optimal performance requires constant learning and adaptation to new challenges.

Best High Head Pump Options for Efficient Water Transfer

| Pump Type | Max Head (m) | Flow Rate (L/min) | Power (HP) | Weight (kg) | Material |

|---|---|---|---|---|---|

| Centrifugal Pump | 50 | 400 | 5 | 25 | Stainless Steel |

| Submersible Pump | 35 | 300 | 2 | 18 | Plastic |

| Diaphragm Pump | 20 | 150 | 1.5 | 10 | Aluminum |

| Gear Pump | 25 | 220 | 3 | 12 | Cast Iron |

Comparative Analysis of High Head Pumps Based on Lift Capacity

When selecting high head pumps, lift capacity is key. According to recent industry reports, pumps can achieve lift heights from 20 to 300 meters. Higher lift capacities often correlate with increased energy consumption. For example, a pump moving water from a lower to a much higher elevation may require significantly more power.

Efficiency varies based on design and materials. Some pumps have composite materials that reduce weight, but these may not always hold up under pressure. Data shows that pumps designed for higher lift applications can operate at about 70% efficiency. However, in real-world use, some units fail to meet those benchmarks, causing operational issues.

Consider the installation site carefully. Terrain can impact the performance of high head pumps. Misalignment or improper setup can lead to underperformance. A poorly installed pump may deliver only 50-60% of its stated capacity. Regular maintenance is essential, yet it's often neglected. Skipping maintenance can decrease efficiency over time and lead to early replacements. Hence, lift capacity must be balanced with reliability and efficiency to ensure optimal water transfer.

Energy Consumption and Efficiency Ratings of Leading Pump Models

When selecting high head pumps, energy consumption is crucial. Many models show varied efficiency ratings. According to a recent industry report, some pumps can have an efficiency rating as low as 50%. This means they waste substantial energy during operation. Understanding these ratings helps users make informed decisions.

Energy-efficient pumps often utilize advanced motor technology. For instance, variable frequency drives (VFDs) are common. These devices enable the pump to adjust its speed based on water demand. Results from various studies indicate that VFD-equipped pumps can reduce energy use by up to 30%. However, initial installation costs can be high.

It’s essential to analyze operational costs over time. Some high head pumps may require more maintenance, increasing their total lifetime expenses. The right choice balances upfront costs and long-term savings. Ignoring these factors can lead to excessive spending. Energy audits and performance assessments can reveal inefficiencies. They provide valuable insights into potential upgrades.

Best High Head Pump Options for Efficient Water Transfer

Selection Criteria for Optimal High Head Pumps in Varying Conditions

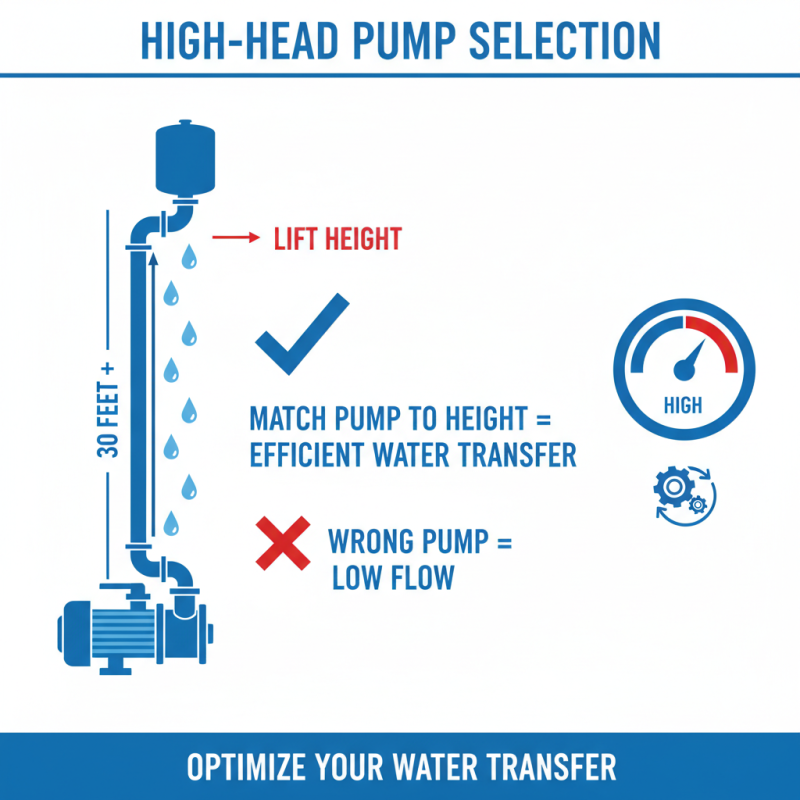

When selecting a high head pump, consider the lift height. This is crucial for water transfer efficiency. Most high head pumps operate effectively at elevations beyond 30 feet. Ensure your pump can handle the specific height required for your application. A pump not suited for the height may struggle, leading to insufficient flow rates.

Next, examine the flow rate. This determines how quickly water moves through the system. Different jobs require different rates. For example, agricultural applications might demand higher flow rates compared to residential uses. Pumping too slowly may hinder productivity. On the other hand, excessive flow can lead to waste and inefficiency.

Durability and maintenance requirements are also essential. Some pumps require frequent servicing, while others are built for longevity. Ideally, the right pump should balance efficiency with minimal upkeep. Observe that higher efficiency often correlates with greater initial costs. Thus, assess long-term benefits versus short-term expenses carefully.

Related Posts

-

What is a High Pressure Water Pump and How Does It Work

-

How to Maintain Boiler Water Quality for Optimal Efficiency?

-

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs

-

What is an Industrial Pump and How Does It Work?

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

Top 10 Multistage Centrifugal Pump Benefits and Applications You Should Know