Contact Us

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

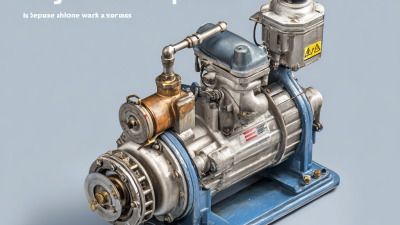

In modern industrial applications, steam systems play a crucial role in various processes, from power generation to food processing and chemical manufacturing. A key component that significantly impacts the performance and efficiency of these systems is the high temp condensate pump. According to the U.S. Department of Energy, properly managed steam systems can exhibit energy savings of up to 20% when equipped with advanced pumping solutions. This optimization is largely attributed to the effective removal and management of condensate, which is essential for maintaining system pressure and maximizing heat recovery.

The high temp condensate pump is specifically designed to operate efficiently at elevated temperatures, ensuring that condensate is effectively returned to the boiler system. Research from industry experts demonstrates that using high temp condensate pumps can reduce energy consumption and improve thermal efficiency, ultimately leading to a lower environmental footprint. As industries increasingly focus on sustainability and energy efficiency, investing in high temp condensate pump technology is becoming an imperative for organizations looking to enhance operational performance and reduce costs in their steam systems.

Importance of High Temp Condensate Pumps in Steam Systems

High temperature condensate pumps play a crucial role in the efficiency and effectiveness of steam systems. These pumps are designed to handle the challenges posed by high-pressure steam, ensuring that condensate—water produced when steam cools and condenses—can be effectively returned to the boiler. This is essential because returning condensate helps conserve energy, reduces water and chemical usage, and minimizes system losses, thereby enhancing overall operational efficiency.

Moreover, the importance of high temp condensate pumps extends to maintaining optimal system pressure and preventing the negative impacts of water hammer and other hydraulic issues. Efficient pumps help to swiftly remove condensate, reducing the risk of steam trapping, which can lead to energy loss and equipment malfunction. In industries that rely on steam for heating and power generation, investing in high-quality condensate pumps not only supports system reliability but also contributes to lower operating costs and extended equipment lifespan.

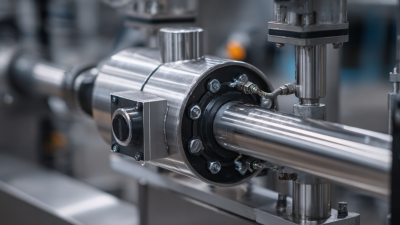

Key Features of High Temperature Condensate Pumps

High temperature condensate pumps are critical components in steam systems, influencing both efficiency and operational reliability. These pumps are designed to handle condensate at elevated temperatures, typically above 200°F, ensuring effective recovery and recycling of steam. According to the American Society of Mechanical Engineers (ASME), improper handling of high-temperature condensate can lead to significant energy losses—up to 30% in some cases—due to inefficient heat recovery processes. Therefore, selecting the right pump can dramatically impact a facility's energy consumption and overall productivity.

When evaluating high-temperature condensate pumps, several key features emerge as vital for optimal performance. Firstly, durable materials such as stainless steel or high-grade cast iron are essential for withstanding the corrosive properties of high-temperature condensate. Additionally, features such as automatic control systems enhance operational efficiency by adjusting pump performance based on real-time condensate flow rates. Industry studies indicate that such automated systems can improve pump efficiency by as much as 25%, reducing both energy usage and operating costs. Investing in high-quality, high-temperature condensate pumps not only optimizes steam system efficiency but also promotes sustainability in industrial operations.

Advantages of Efficient Condensate Management in Steam Operations

Efficient condensate management is crucial in steam operations, significantly impacting overall energy efficiency and cost savings. According to the U.S. Department of Energy, poorly managed condensate can waste as much as 10-20% of the energy generated by a steam system. Implementing a high-temp condensate pump ensures that condensate is quickly and effectively returned to the boiler, promoting optimal thermal efficiency. This mechanism not only prevents energy loss but also helps maintain the operational integrity of the system, reducing instances of water hammer and corrosion caused by stagnant water.

Moreover, effective condensate management fosters a more sustainable operation. The Steam Trap Alliance reported that effective condensate recovery can save facilities up to 2,000 gallons of water per day for every 1 million BTU/hour of steam generated. By investing in high-temp condensate pumps, organizations can improve their resource recovery rates and decrease their reliance on municipal water systems, aligning with modern sustainability goals while enhancing their bottom line. As industries strive for higher efficiency and lower environmental impact, the role of condensate management becomes increasingly relevant.

Advantages of Efficient Condensate Management in Steam Operations

Common Applications for High Temperature Condensate Pumps

High temperature condensate pumps play a vital role in various industrial applications, ensuring the efficient recycling of steam back into the system. One common use is in power plants, where steam turbines generate electricity. Here, condensate pumps remove excess condensation and maintain optimal pressure levels, enhancing the overall efficiency of the system. Similarly, in food processing facilities, these pumps help manage steam in pasteurization and cooking processes, ensuring product safety and quality by controlling temperature and pressure.

When considering high temperature condensate pumps for your operations, it's crucial to select models that are designed to handle specific temperatures and pressures. **Tip:** Always check the material compatibility of the pump with the fluid being handled to prevent corrosion and ensure longevity.

Additionally, chemical manufacturing facilities often rely on high temperature condensate pumps to facilitate the distillation process where heat exchange is critical. **Tip:** Regular maintenance and monitoring of the pump’s performance can prevent unexpected breakdowns and enhance system reliability. Choosing the right pump not only improves efficiency but also contributes to safety and product integrity across different industries.

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems - Common Applications for High Temperature Condensate Pumps

| Application | Temperature Range (°F) | Key Features | Benefits |

|---|---|---|---|

| Power Generation | 250 - 400 | High efficiency, durable materials | Increased energy efficiency, reduced emissions |

| Chemical Processing | 200 - 350 | Corrosion-resistant, high-pressure capability | Improved process reliability, enhanced safety |

| Food and Beverage Industry | 180 - 300 | Sanitary design, easy cleaning | Compliance with regulations, improved hygiene |

| Textile Manufacturing | 220 - 350 | High flow rates, reliable performance | Optimized production processes, less downtime |

| HVAC Systems | 200 - 300 | Variable speed control, energy-efficient | Lower operating costs, improved comfort levels |

Maintenance Best Practices for High Temp Condensate Pumps

Effective maintenance of high-temperature condensate pumps is crucial for the longevity and efficiency of steam systems. Regular checks on the pump components should be conducted to prevent operational failures. Ensure that seals and gaskets are intact, as these parts are essential for maintaining pressure and preventing leaks.

Tips: Schedule quarterly inspections to assess the performance of the pump. A proactive approach allows for early detection of wear and tear, which can minimize costly repairs down the line. Additionally, maintain a log of all maintenance activities to track performance trends over time.

Another vital aspect of maintenance is keeping the pump's motor and electrical connections clean and well-lubricated. Dust and debris can lead to overheating and operational inefficiencies.

Tips: Implement a regular cleaning schedule to remove dust and grease buildup. Utilize appropriate lubricants recommended by the manufacturer to ensure smooth operation and reduce friction within moving parts. By adhering to these maintenance best practices, you can optimize the performance and reliability of high-temperature condensate pumps, ensuring your steam system operates at peak efficiency.

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries

-

What is a High Pressure Water Pump and How Does It Work

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs