Contact Us

Top 10 High Temperature Pump Tips You Need to Know for Efficient Operation

In the world of industrial operations, the efficiency of a high temperature pump is critical to maintaining optimal performance and safety. According to Dr. John Smith, a renowned expert in pump technology, “Understanding the nuances of high temperature pumps can significantly enhance operational longevity and efficiency.” This insight emphasizes the importance of knowledge in this specialized field, where the ramifications of improper use can lead to significant downtime and financial loss.

High temperature pumps are designed to handle fluids at elevated temperatures, making them indispensable in industries such as oil and gas, chemical processing, and power generation. However, their operation requires careful consideration of factors like material selection, system design, and maintenance practices. By following expert recommendations and best practices, operators can ensure that these pumps perform at their peak, minimizing risks associated with high temperature applications.

As we explore the top 10 essential tips for high temperature pump operation, we aim to equip professionals with the knowledge necessary to optimize their systems. Adhering to these guidelines not only promotes efficiency but also extends the lifespan of the equipment, ultimately contributing to improved productivity across various sectors.

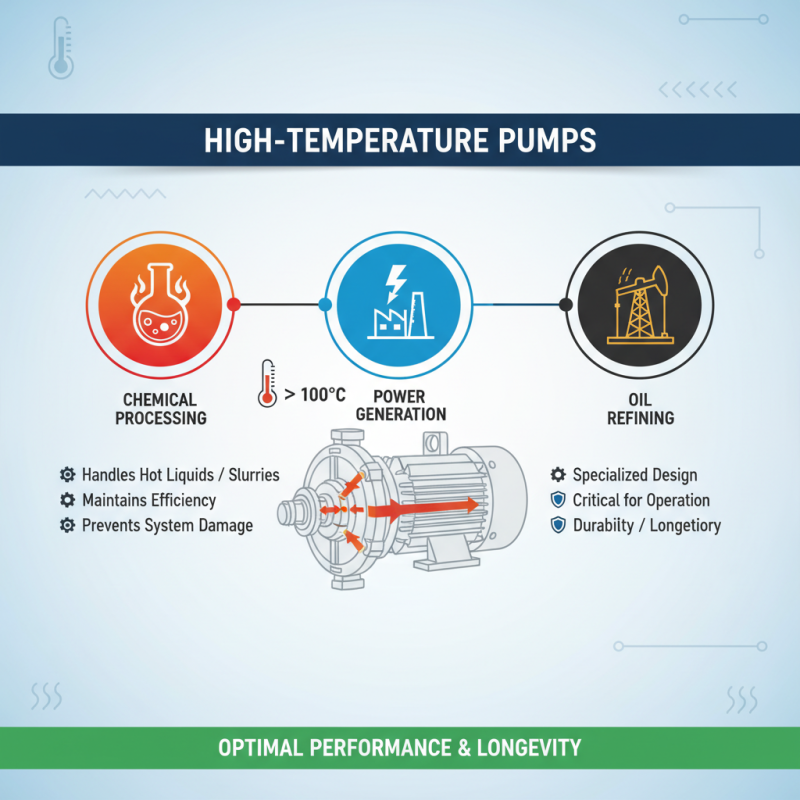

Understanding High Temperature Pumps: Definition and Applications

High temperature pumps are specialized devices designed to handle fluids at elevated temperatures, typically exceeding 100°C. These pumps serve critical roles across various industries, including chemical processing, power generation, and oil refining. Their primary function is to transport hot liquids or slurries while maintaining efficiency and preventing damage to both the pump and the system in which they operate. Understanding the design and operational requirements of high temperature pumps is essential for optimal performance and longevity.

Applications of high temperature pumps are diverse, ranging from transferring hot water in power plants to moving molten materials in manufacturing processes. Their construction often involves robust materials that can withstand thermal stress and corrosion, ensuring reliability under extreme conditions. Additionally, these pumps may integrate features such as thermal insulation and advanced sealing technologies to enhance efficiency and prevent leaks. As industries continue to evolve, the demand for high temperature pumps will likely increase, emphasizing the importance of selecting the right type for specific applications.

Key Operational Parameters for High Temperature Pump Efficiency

When operating high temperature pumps, understanding key operational parameters is crucial for ensuring efficiency and longevity. One of the most critical factors is the temperature range of the fluid being pumped. High temperatures can significantly affect the viscosity of fluids, leading to changes in flow rates. Operators should monitor the pump's design specifications closely to ensure that the materials used can withstand the operational temperatures without compromising integrity.

Another important parameter is the suction lift and discharge pressure. Maintaining optimal pressure levels can prevent cavitation, which not only minimizes wear on the pump but also enhances performance. Additionally, regular maintenance checks on seals and bearings are essential to mitigate issues caused by thermal stress. Ensuring that these components are in good condition can drastically improve the overall efficiency of the pump in high-temperature applications. Adequate cooling systems may also be necessary in some setups to maintain operational stability, further enhancing efficiency during prolonged periods of use. By focusing on these key operational parameters, efficient and reliable high temperature pump performance can be achieved.

Materials and Design Considerations for High Temperature Pumps

When selecting materials for high temperature pumps, the primary consideration is their ability to withstand elevated temperatures without compromising structural integrity or performance. Commonly used materials include high-grade stainless steels and special alloys that offer excellent strength and corrosion resistance at high temperatures. Additionally, the choice of elastomers and seals is crucial, as these components must retain their flexibility and sealing capabilities even under thermal stress. The compatibility of these materials with the pumped media is also vital; for instance, certain materials may degrade when exposed to aggressive chemicals at high temperatures.

Design considerations for high temperature pumps should focus on optimizing the pump configuration to minimize thermal expansion and ensure efficient fluid flow. The pump casing must be robust enough to handle the increased pressures that often accompany high temperature operations, while impellers need to be specifically designed to maintain performance without excessive wear. Attention to cooling methods is also essential, as overheating can lead to equipment failure. Incorporating features like thermal shields or integrating effective heat dissipation mechanisms can enhance reliability, ensuring the pump operates efficiently throughout its lifecycle.

Maintenance Practices to Extend High Temperature Pump Lifespan

High temperature pumps play a crucial role in various industrial applications, and proper maintenance practices are essential to ensure their longevity and efficient operation. Regular inspection of pump components, such as seals, bearings, and impellers, helps identify wear and tear that could lead to performance issues. It's advisable to establish a routine maintenance schedule that includes checking for leaks, vibration analysis, and temperature monitoring. These proactive measures not only prevent downtime but also enhance the overall efficiency of the system.

Another key practice is to ensure that the operating environment remains within the pump's designed temperature range. Extreme temperatures can compromise the integrity of materials used in pumps, leading to premature failure. Utilizing cooling systems or heat shields can mitigate excessive heat exposure. Furthermore, maintaining the correct lubrication levels is critical, as high temperatures can degrade lubricants faster. Regularly replacing lubricants and ensuring they are suitable for high temperature operations helps maintain smooth operation and reduces friction-related wear. By adhering to these maintenance practices, operators can extend the lifespan of high temperature pumps and optimize their performance.

Troubleshooting Common Issues in High Temperature Pump Operation

Troubleshooting common issues in high temperature pump operation requires a deep understanding of both the equipment and the materials being pumped. According to a recent industry report by the Pump Industry Experts, more than 25% of high temperature pump failures are attributed to inadequate thermal management. Elevated temperatures can cause premature wear and failures in seals, bearings, and even the pump casing itself. Therefore, regular monitoring of temperature thresholds and ensuring that thermal insulation is intact are crucial for maintaining operational efficiency.

Another common issue that arises during the operation of high temperature pumps is cavitation. This phenomenon occurs when vapor bubbles form in the pump due to low-pressure zones, which can lead to significant damage upon collapse. Studies show that cavitation can reduce pump efficiency by up to 30% and contribute to increased maintenance costs. Implementing appropriate measures—such as maintaining optimal suction conditions and verifying flow rates—can help alleviate this problem and enhance the longevity of the pump system. Regular inspections and adherence to operational guidelines are key to minimizing downtime and ensuring that pumps are functioning at their best.

Related Posts

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

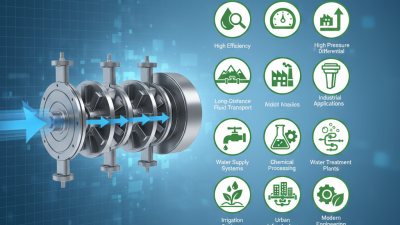

Top 10 Multistage Centrifugal Pump Benefits and Applications You Should Know

-

2025 Top 10 Boiler Feed Tanks for Efficient Water Management

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

7 Essential Tips for Choosing the Right Vertical Centrifugal Pump for Your Needs