Contact Us

2026 How to Choose a High Pressure Water Pump for Your Needs?

Choosing the right water pump high pressure for your specific needs can be daunting. Various factors come into play. Understanding these factors can help you make better decisions.

A high pressure water pump is essential for numerous applications. It serves both residential and industrial purposes. Think about the tasks you will perform. This will guide your choice effectively.

Not all pumps are created equal. Some may not meet your requirements. Reflect on their capacity, inlet size, and energy consumption. It’s crucial to assess your personal or professional needs carefully. The right choice can save you time and prevent frustration.

Understanding High Pressure Water Pumps: Key Features to Consider

Choosing a high pressure water pump requires careful consideration of several key features. First, look at the pump's flow rate. This is crucial for determining how much water it can deliver in a given time. A higher flow rate means the pump will satisfy your needs more efficiently. Next, pay attention to the pressure rating. This will indicate how much pressure the pump can generate, affecting its ability to perform tasks like cleaning or spraying.

Material quality is another vital aspect. Pumps made from durable materials can withstand harsh conditions. Corrosion-resistant options are often best for outdoor use. Portability also matters. Some jobs may require moving the pump frequently. A lightweight design with sturdy wheels can greatly enhance usability. Additionally, evaluate the pump's maintenance requirements. A model that is easy to maintain can save time and costs in the long run.

Considering energy efficiency is essential, too. A pump that consumes more power than necessary can lead to higher bills. However, models that save energy may come with a higher upfront cost. Reflect on the balance between cost and efficiency. Lastly, think about the application you have in mind. Different tasks may demand different specifications. It’s critical to match the pump's features with your specific needs.

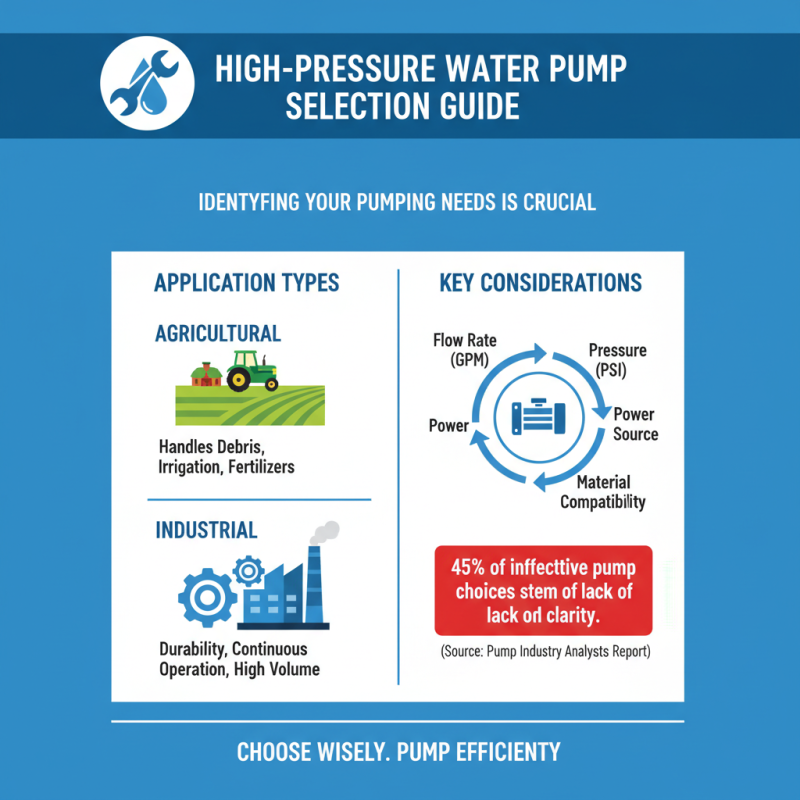

Identifying Your Specific Pumping Needs and Applications

When choosing a high-pressure water pump, identifying your specific pumping needs is crucial. Different applications require various features and specifications. For instance, agricultural uses might need a pump that can handle debris, while industrial applications often focus on durability and continuous operation. A report by the Pump Industry Analysts suggests that 45% of ineffective pump choices stem from a lack of clarity about applications.

Understanding the flow rate is vital. Many pumps operate efficiently at rates between 10 to 100 gallons per minute. However, some projects may require incredibly precise flow control. Inconsistent selection can lead to issues like cavitation, reducing the pump's lifespan and effectiveness. It’s essential to also consider the total dynamic head, as this determines the pump’s efficiency in delivering water to the desired location. A mismatch here can significantly impact performance.

Another element to reflect on is noise levels, especially for residential areas. High-pressure pumps can generate considerable sound, affecting daily life. While some might overlook this factor, ignoring it could lead to community complaints. Additionally, weight and size matter for mobile or confined space operations. Often, the dimensions can limit options, so take care in assessing the installation location. Balancing these needs allows for a more tailored choice.

Evaluating Pump Performance Metrics: Pressure, Flow Rate, and Power

When selecting a high-pressure water pump, evaluating pump performance metrics is crucial. Key metrics include pressure, flow rate, and power. For instance, a pump with high pressure typically exceeds 150 psi, making it ideal for tasks like power washing or lawn irrigation. Yet, not all high-pressure pumps deliver optimal flow rates. A balance between pressure and flow is essential.

According to industry reports, many users struggle to select pumps that match their needs. A pump rated for 3,000 psi may offer a low flow rate of just 1.5 GPM. This mismatch can lead to frustrated users. Understanding one's requirements is vital.

Power consumption also plays a significant role. A pump’s motor power determines efficiency and operational costs. Higher power often means better performance, but not always. Some advanced models may have lower wattage yet outperform conventional options. Exploring these nuances can improve purchasing decisions. A thoughtful approach can lead to a more satisfied user experience.

Exploring Different Types of High Pressure Water Pumps Available

When selecting a high-pressure water pump, it’s essential to explore the variety of types available. Centrifugal pumps are common choices. They are effective for transferring large volumes of water. Heavy-duty models can handle thick fluids. However, they may lack the pressure required for certain applications, like power washing.

Another type is the positive displacement pump. This type provides consistent pressure, making it ideal for tasks that require precision. They work by trapping a fixed amount of fluid and forcing it through the outlet. But, they can be more expensive and harder to maintain. Users should reflect on their specific needs before choosing.

Finally, diaphragm pumps are worth considering, especially for chemicals and slurries. They can handle abrasive materials well. While they offer versatility, they may not be suitable for high flow rates. Understanding these types helps in making the right choice for specific tasks. Each type has strengths and weaknesses that require careful consideration.

Maintenance Tips for Longevity and Efficiency of Your Pump

Maintaining a high-pressure water pump is crucial for its longevity and efficient performance. Regular maintenance can prevent unexpected breakdowns and costly repairs. Start by checking the filters and cleaning them as needed. Clogged filters can reduce the pump’s efficiency. This simple step ensures that debris does not hinder performance.

Another important tip is to regularly inspect the pump's seals and fittings. Look for any signs of wear or leaks. Over time, seals can degrade, leading to operational inefficiencies. Addressing these issues early can save you headaches later.

Don't forget to monitor the water levels and pressure settings. Operating the pump at incorrect pressure can lead to premature wear. Keep a journal of maintenance activities. Documenting each service can help identify patterns in performance. This practice sheds light on potential problems. Regular check-ups won’t eliminate all issues, but they improve reliability.

High Pressure Water Pump Comparison

This bar chart compares three different high-pressure water pumps based on important specifications: flow rate (GPM), pressure (PSI), power consumption (HP), weight (lbs), and noise level (dB). Each dataset represents a different pump, allowing users to easily visualize the strengths and weaknesses of each option.

Related Posts

-

What is a High Pressure Water Pump and How Does It Work

-

Best High Pressure Pumps for Water in 2023 Top Options Reviewed

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

2025 How to Choose the Right Boiler Feed Tank for Your Needs

-

Why is a Steam Condensate Return Pump Essential for Energy Efficiency?