Contact Us

2026 How to Choose Welded Wire Mesh for Your Projects?

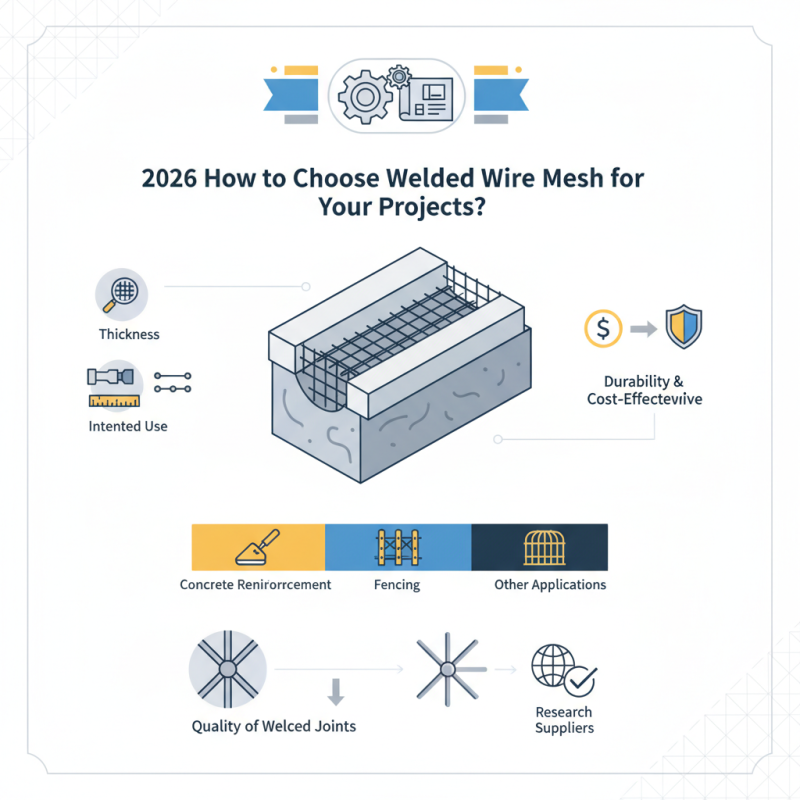

Choosing the right welded wire mesh for your projects can be challenging. Expert James Halston, a recognized authority in the welded wire mesh industry, states, “Quality mesh is the backbone of any sturdy construction.” When selecting welded wire mesh, consider the specific needs of your project. Thickness, spacing, and intended use are all crucial factors.

welded wire mesh serves diverse functions, from concrete reinforcement to fencing. The right choice can greatly influence your project's durability and cost-effectiveness. Improper selection might lead to structural issues. Reflect on the mesh’s applications—different projects require different specifications.

Moreover, don’t overlook the quality of the welded joints. Weak joints can compromise the overall strength. It's vital to analyze suppliers carefully. Not all products meet the same standards. Invest time in research to avoid regret. Your final choice in welded wire mesh will impact both performance and safety.

Understanding Welded Wire Mesh: Basic Concepts and Applications

Welded wire mesh is essential in construction and agriculture. It consists of durable wires that are welded together in a grid pattern. This structure provides strength and flexibility, making it suitable for various applications. According to a recent industry report, the global welded wire mesh market is expected to reach $3.5 billion by 2026, reflecting its growing importance.

In agriculture, welded wire mesh is commonly used for fencing and animal enclosures. It prevents livestock from escaping while keeping predators at bay. In construction, it serves as reinforcement in concrete structures. Research indicates that welded wire mesh can improve concrete durability by up to 30%. However, choosing the right mesh for projects isn't always straightforward. Factors like wire diameter and spacing impact both strength and cost.

Installation can be challenging. Misalignment during installation can compromise the mesh's effectiveness. It's crucial to ensure proper fittings and supports. Many overlook these details, leading to higher long-term costs. Whether for a small garden or a large construction site, understanding welded wire mesh is vital for successful project completion.

Key Factors to Consider When Choosing Welded Wire Mesh

When choosing welded wire mesh, several factors come into play. The gauge of the wire is critical. Thinner wires are more flexible but less durable. A typical gauge ranges from 8 to 14. According to industry reports, a gauge of 10 offers a balance between strength and workability. This makes it ideal for various applications, including fencing and concrete reinforcement.

Mesh size is another important consideration. Standard openings vary from 1 inch to 6 inches. Smaller openings may prevent debris intrusion but can be more challenging to work with. A study by the American Wire Mesh Association indicates that 2-inch openings are effective for agricultural uses, while 4-inch openings are better for general construction.

Evaluate the intended use. For high-stress situations, thicker wire and tighter mesh are necessary. The durability of the mesh material also affects longevity. Galvanized mesh resists rust, while vinyl-coated options add another layer of protection. Interestingly, some consumers overlook the environment's impact on mesh. Humidity can weaken unprotected wire over time, leading to premature failure. Understanding these factors helps ensure that your choice is not just effective but also cost-efficient.

2026 How to Choose Welded Wire Mesh for Your Projects? - Key Factors to Consider When Choosing Welded Wire Mesh

| Dimension | Wire Diameter (mm) | Opening Size (mm) | Sheet Size (m²) | Uses |

|---|---|---|---|---|

| 1.0 x 1.0 | 1.0 | 25 x 25 | 2 | Gardening, fencing |

| 1.0 x 1.5 | 1.2 | 50 x 50 | 3 | Animal enclosures, construction |

| 2.0 x 1.0 | 1.5 | 20 x 20 | 4 | Security screens, safety barriers |

| 2.5 x 1.2 | 2.0 | 30 x 30 | 5 | Frameworks, reinforcement |

| 3.0 x 1.5 | 2.5 | 40 x 40 | 6 | Industrial applications, shelters |

Comparing Different Materials and Coatings for Welded Wire Mesh

Choosing the right welded wire mesh requires understanding different materials and coatings. The mesh material can include steel, stainless steel, or galvanized options. Steel is strong but may rust without a proper coating. Stainless steel offers excellent corrosion resistance but can be more expensive. Galvanized wire mesh has a protective zinc coating, making it a popular choice for outdoor projects.

Consider the environment where the mesh will be used. In humid areas, stainless steel or galvanized mesh can prolong life. For temporary structures, lower-cost steel might be sufficient. Think carefully about the specific project needs. Using the wrong material can lead to issues down the line.

Tips: Always examine the coating thickness. A thicker layer can provide better protection. Check for any signs of wear or damage before purchasing. Sometimes, damaged mesh may still be usable but needs careful evaluation. Proper installation is crucial for longevity. Avoid compromising on quality, even for budget-friendly options.

Sizing and Gauge: How to Determine the Right Specifications

Choosing the right welded wire mesh can be daunting. Start with sizing and gauge. These factors greatly influence the performance of your projects. The mesh size refers to the number of openings per inch. Smaller openings offer better containment but limit airflow.

Gauge refers to the wire thickness. Thicker wires provide more strength but can add weight. For example, a 14-gauge wire is stronger than a 16-gauge wire. However, think about the project’s needs. Too thick can complicate handling. You might need more effort to cut or bend.

**Tip:** When selecting wire mesh, consider the environment. For outdoor projects, rust-resistant options may be necessary.

Consider the application carefully. For fencing, durability is key. For crafts, lighter gauges might suffice. Always balance strength and flexibility. Make revisions when working with different materials. It’s okay to change your mind. Use samples before committing.

**Tip:** Testing small sections can save you time. Adjust your choices based on real-life trials. Adaptability is crucial in selecting the best mesh for your needs.

2026 Welded Wire Mesh Specifications

Common Applications and Best Practices for Using Welded Wire Mesh

Welded wire mesh serves various applications, making it a versatile choice for projects. It's commonly used in construction, fencing, and even gardening. The galvanized finish adds durability, making it resistant to corrosion. However, choosing the right gauge is crucial. A thicker wire may provide more strength, but it can be harder to work with.

In gardening, welded wire mesh can support plants or protect them from pests. It’s useful for building trellises or fencing off garden areas. Small openings can deter rodents effectively. On the construction site, it’s vital for concrete reinforcement. While it helps provide structural integrity, care must be taken to ensure proper installation. A slight misalignment in the mesh can lead to weak points in the structure.

Best practices involve considering the environment where the mesh will be used. Factors like moisture and exposure to chemicals should influence your choice. It’s easy to overlook these, leading to premature failure of the mesh. Always double-check measurements before cutting, as mistakes can waste materials. Even minor errors can turn into costly problems down the line. Keeping these reflections in mind will guide you toward more successful projects using welded wire mesh.