Contact Us

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs

In today's industrial landscape, maximizing efficiency while minimizing operational costs is paramount for businesses looking to maintain a competitive edge. One critical component that directly influences these two aspects is the boiler feed tank. As highlighted in the 2022 Energy Efficiency Report by the American Society of Mechanical Engineers (ASME), properly designed and operated boiler feed tanks can significantly enhance a boiler system's overall performance, leading to energy savings of up to 20% over time. This staggering figure underscores the importance of integrating effective boiler feed tank systems in industrial operations.

Moreover, the Global Steam Boiler Systems Market Report reveals that inefficiencies in steam systems, often originating from suboptimal boiler feed tank management, can lead to excess fuel consumption and increased greenhouse gas emissions. By employing advanced technologies and best practices for boiler feed tanks, facilities can not only reduce their carbon footprint but also achieve a return on investment within a few short years. Emphasizing the role of boiler feed tanks in achieving operational excellence is essential for industries striving to lower costs and enhance sustainability in an increasingly eco-conscious market.

The Role of Boiler Feed Tanks in Energy Conservation Strategies

Boiler feed tanks play a crucial role in energy conservation strategies within industrial and commercial settings. By acting as a buffer for water before it enters the boiler system, these tanks ensure that thermal efficiency is maximized. They allow for the pre-heating of the feed water, which significantly reduces the energy required to reach the necessary temperature for steam generation. This pre-heating process not only conserves energy but also leads to a reduction in fuel costs, ultimately supporting a more sustainable operation.

Moreover, boiler feed tanks contribute to the overall efficiency of the boiler system by maintaining consistent water levels, which prevents the boiler from overheating or running dry. This helps in minimizing abrupt energy fluctuations, thereby optimizing fuel consumption. Additionally, by facilitating the recovery of condensate from the steam system, feed tanks enable the reuse of treated water, further enhancing water efficiency. Overall, the integration of boiler feed tanks within energy conservation strategies is essential for maximizing efficiency and minimizing operational costs in boiler systems.

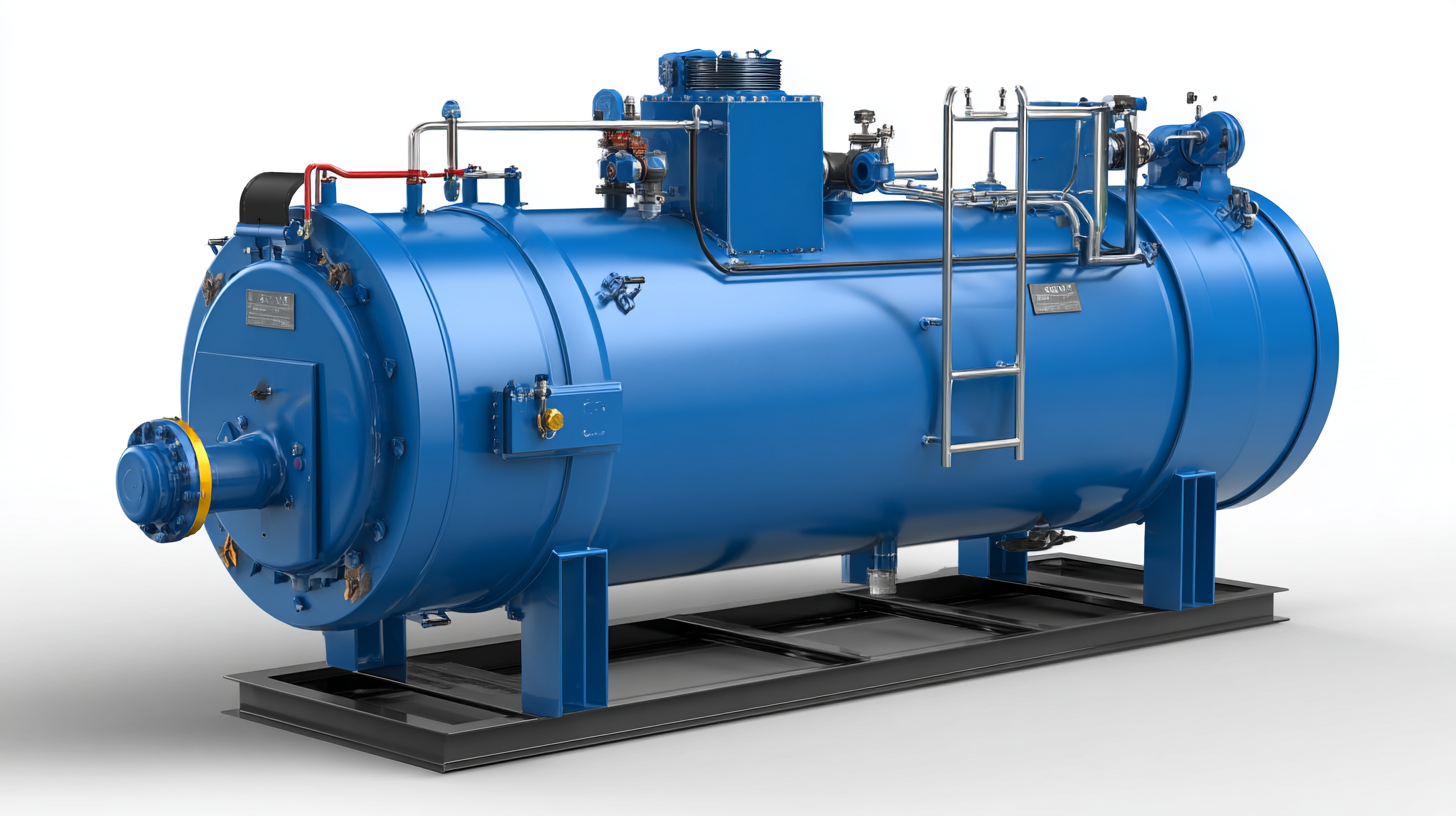

Key Components of Efficient Boiler Feed Tank Design

The design of an efficient boiler feed tank is crucial for optimizing the performance of boiler systems. Key components such as level sensors, pumps, and heating elements play significant roles in the operation of these tanks. For instance, advanced level sensors equipped with differential pressure technology can enhance accuracy, ensuring that the tank maintains optimal water levels. According to a report by the American Society of Mechanical Engineers (ASME), precise level control can improve system reliability, potentially extending the life of boiler components by 20%.

Moreover, integrating variable speed pumps into the feed tank system can result in energy savings of up to 30%. These pumps adjust flow rates based on real-time demand, reducing unnecessary energy consumption. A study by the Energy Efficiency Improvement Program indicates that implementing such technologies can lead to operational cost reductions of around 15%, significantly impacting overall efficiency and sustainability. Additionally, using insulation materials for heating elements can prevent heat loss, which not only conserves energy but also enhances water temperature stability, crucial for efficient boiler operation.

Cost-Benefit Analysis: Investing in Boiler Feed Tanks

Investing in boiler feed tanks is crucial for optimizing system efficiency and reducing operational costs. A thorough cost-benefit analysis reveals that the initial expenditure on these tanks is outweighed by long-term savings and operational advantages. Boiler feed tanks ensure a consistent water supply to the boiler, which helps to maintain optimal pressure and temperature levels. This reliability minimizes the wear and tear on boiler components, extending their lifespan and reducing maintenance expenses.

Furthermore, the presence of a boiler feed tank can facilitate the recovery of valuable energy resources. By allowing for pre-heating of feedwater, these tanks help decrease the amount of energy needed to achieve desired steam pressures, thus lowering fuel costs. The tank additionally acts as a buffer for sudden changes in steam demand, effectively smoothing out the operational load on the boiler. Ultimately, the combination of enhanced efficiency and reduced energy consumption presents a compelling case for the strategic investment in boiler feed tanks, leading to substantial cost savings over time.

Best Practices for Maintenance and Operation of Feed Tanks

To ensure the optimal performance of boiler feed tanks, adhering to best practices for

maintenance and operation is crucial. Regular inspections should be conducted, focusing on critical components

such as pumps, valves, and level indicators. This proactive approach helps identify potential issues before they escalate,

reducing downtime and maintenance costs. Additionally, maintaining clean and efficient feed water quality is essential;

impurities can lead to corrosion and scaling, ultimately harming boiler efficiency.

Moreover, implementing a routine cleaning schedule for the feed tank itself can greatly enhance its operational efficiency.

Sediment accumulation can hinder performance, so periodic removal of sludge and debris is necessary. Furthermore, monitoring the temperature

and pressure levels within the tank ensures that the system operates within safe limits, facilitating optimal energy usage.

Training staff on the correct procedures for operating and maintaining feed tanks contributes to a culture of safety and efficiency,

further reducing operational costs and improving overall system reliability.

Case Studies: Successful Implementation of Boiler Feed Tanks in Industry

In the industrial sector, boiler feed tanks play a crucial role in enhancing operational efficiency and reducing costs. A prominent example of successful implementation can be seen in the manufacturing industry, where a major automotive producer integrated a boiler feed tank system into its facility. This strategic move allowed the company to maintain a constant supply of pre-heated water to its boilers, significantly increasing thermal efficiency and minimizing energy consumption. As a result, the plant reported a 15% reduction in energy costs annually, demonstrating how effectively managing water feed systems can lead to substantial savings.

Another notable case is found in the pharmaceutical industry, where a leading company adopted advanced boiler feed tank technology to meet stringent regulatory standards. By utilizing a closed-loop feed tank system, the company improved water quality control, which is vital in maintaining the integrity of its production processes. The implementation not only resulted in enhanced operational reliability but also decreased the downtime typically caused by boiler maintenance. As a consequence, the pharmaceutical firm experienced a 20% increase in production output, further highlighting the critical role of properly designed boiler feed tanks in achieving competitive advantage in various industries.

Impact of Boiler Feed Tanks on Efficiency and Cost Reduction

Related Posts

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs