Contact Us

Why Are Industrial Condensate Pumps Essential for Efficient Water Management?

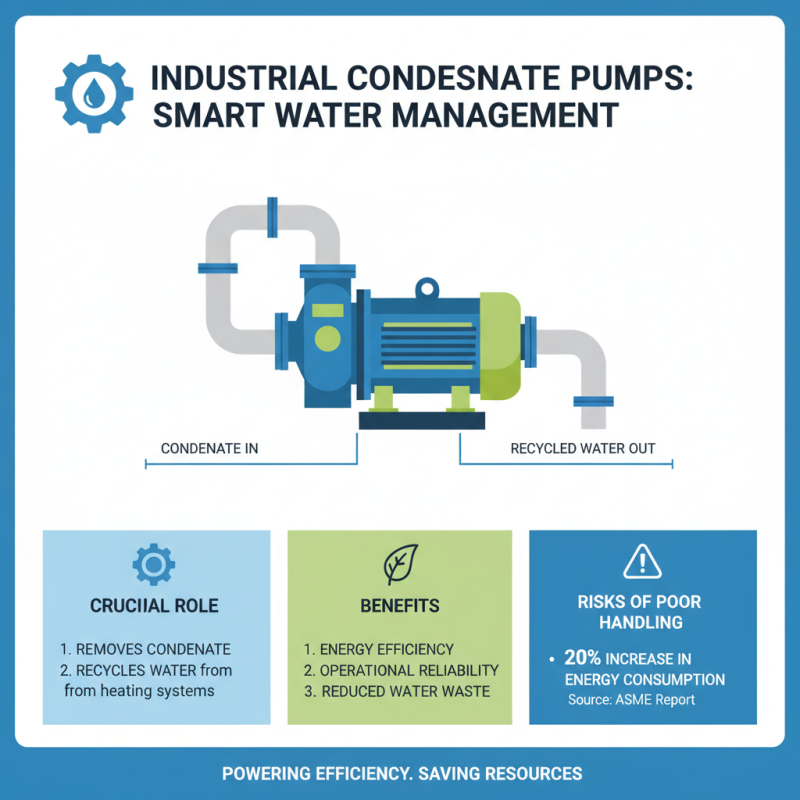

Water management is a critical aspect of many industrial processes. An effective method to achieve this is through the use of an industrial condensate pump. According to James R. Miller, an expert in industrial water systems, "An industrial condensate pump is key to maintaining system efficiency." His insights highlight the vital role these pumps play in optimizing water management strategies.

Industrial condensate pumps help to remove excess condensate from steam systems. This process prevents water buildup that can lead to inefficiencies or even system failures. They ensure that steam traps and equipment function correctly by maintaining the required pressure levels. Without proper management, facilities might face unexpected downtime and costly repairs.

Yet, many industries still overlook the importance of these pumps. This neglect can result in significant operational challenges. Understanding the necessity of an industrial condensate pump is not just beneficial—it is essential for effective water management. Each facility must assess its current systems and implement necessary improvements. Balancing efficiency with sustainability remains a constant challenge for industry leaders.

Importance of Water Management in Industrial Settings

Water management is vital in industrial settings. Industries consume over 20% of global freshwater resources. Improper management leads to waste. Water scarcity is becoming a pressing issue. In factories, efficient water use can reduce costs and improve sustainability.

Condensate pumps play a key role in this strategy. They ensure that wastewater is removed quickly and efficiently. This prevents flooding and equipment damage. Unmanaged water can lead to increased operational expenses. In the U.S., businesses lose approximately $500 billion annually due to inefficiencies.

Implementing effective water management systems is not just about saving money. It fosters a culture of responsibility. Companies can face scrutiny if they are perceived as wasteful. Being proactive in managing water usage can enhance a company’s reputation. Efforts to conserve can also lead to innovations and improvements.

Role of Industrial Condensate Pumps in Water Management

Industrial condensate pumps play a vital role in managing water efficiently. They help in collecting and removing condensate, a byproduct of heating processes. This is essential in industries where steam systems are employed. By quickly pumping away excess water, they prevent flooding and equipment damage. Without them, operations can be hindered. Equipment may fail due to increased moisture levels.

Effective water management hinges on the reliability of these pumps. They help maintain optimal humidity levels. Yet, not all systems are designed equally. Some pumps may require frequent maintenance. This can lead to unexpected downtime. It's crucial to monitor their performance consistently. Failure to do so might result in larger water management issues.

In addition, understanding the right size and type of pump is essential. Choosing the wrong equipment can lead to inefficiencies. Regular inspections and upgrades are necessary. Over time, wear and tear can impact performance. Industries must remain proactive to ensure seamless operations. Proper water management is not just about equipment; it's about creating a reliable system.

How Condensate Pumps Improve Energy Efficiency and Sustainability

Industrial condensate pumps play a crucial role in water management. They help remove condensate produced during industrial processes. This action prevents water accumulation, which can lead to inefficiencies. According to a report by the U.S. Department of Energy, inefficient water management can increase energy costs by 20%. Condensate pumps effectively handle water, resulting in more streamlined operations.

Improving energy efficiency and sustainability is a key benefit of condensate pumps. Efficient pumps lead to lower energy consumption. The American Council for an Energy-Efficient Economy estimates that proper condensate removal can save facilities up to 10% in energy costs. This means that the investment in efficient pumps pays off over time. However, not all systems are optimized. Many industries still struggle with outdated equipment, reflecting the need for modernization.

Data indicates that facilities using condensate pumps experience fewer operational interruptions. These interruptions typically stem from water backups. Ensuring a steady flow enhances productivity. Yet, awareness about these pumps is lacking in some sectors. A surprising number of companies remain unaware of the benefits. Upgrading systems may require time and financial outlay, but the long-term sustainability gains are clear. Investing in modern condensate management should be a priority for industrial leaders.

Key Features of Effective Industrial Condensate Pumps

Industrial condensate pumps play a crucial role in efficient water management. These pumps ensure that condensate from heating systems is effectively removed and recycled. Without them, industries can face serious operational inefficiencies. According to a report by the American Society of Mechanical Engineers, improper condensate handling can lead to a 20% increase in energy consumption.

Key features of effective industrial condensate pumps include durability and energy efficiency. Robust materials ensure longevity, even in harsh environments. Many pumps also incorporate variable speed drives. This technology can adjust performance based on real-time requirements, saving substantial energy. Research has shown that optimized pump systems can reduce operating costs by up to 30%.

However, not all industrial pumps are created equal. Some may not have enough capacity for larger systems, leading to potential downtime. Improper installation can diminish pump performance as well. Data from the Energy Efficiency Network indicates that over 15% of industries experience pump failures due to inadequate maintenance. Regular checks are essential. This small oversight can result in significant waste and increased operational costs.

Challenges and Solutions in Condensate Pump Maintenance and Operation

Maintaining industrial condensate pumps presents several challenges. These pumps often face wear and tear, particularly in high-use environments. Regular inspections are crucial to identify potential issues early. Corrosion can occur in wet environments, damaging pump components. Ignoring these signs may lead to unexpected breakdowns. Operators need to stay vigilant and proactive.

Another challenge lies in the proper operation of condensate pumps. Operators may overlook essential training. This can lead to improper usage and reduced efficiency. Familiarity with pump specifications is vital. Workers should be trained on how to troubleshoot basic problems. Simple errors can result in costly downtime. A culture emphasizing continuous learning can help alleviate this issue.

Additionally, the environment around pumping systems can introduce complications. Dust and debris can impede performance. Ensuring cleanliness around the units is important. Operators should implement regular cleaning schedules to maintain optimal functioning. It’s necessary to involve all team members in this effort. The focus should always be on safety and efficiency, even in day-to-day tasks. Ultimately, good practices foster a more reliable water management system.

Related Posts

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

2026 How to Choose the Right Commercial Condensate Pump for Your Needs?

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs