Contact Us

What is an Industrial Pump and How Does It Work?

Industrial pumps play a crucial role in various industries. They help move fluids like water, chemicals, and slurries. These pumps are vital in manufacturing, agriculture, and construction. Their design and function are essential for efficient operations.

Understanding how industrial pumps work is important. Different types of pumps suit different applications. Centrifugal pumps use spinning motion, while positive displacement pumps push fluids in a specific manner. Each type has its benefits and limitations.

It's clear that choosing the right pump can be challenging. Factors like fluid properties and flow rates influence decisions. Maintenance and operating costs should also be considered. Reflecting on these aspects leads to better pump selection and improved performance.

What is an Industrial Pump? Definition and Key Features

Industrial pumps are critical components in various sectors, including manufacturing, chemical processing, and water treatment. These devices are designed to move fluids efficiently. They can handle different types of liquids, including slurries and viscous fluids. According to a report by Research and Markets, the industrial pump market was valued at $68 billion in 2021 and is expected to grow at a CAGR of 4.3% from 2022 to 2029. This growth highlights their importance in many operations.

Key features of industrial pumps include their ability to handle high pressures and large volumes. They often come in various types, such as centrifugal pumps and positive displacement pumps. Centrifugal pumps are common due to their efficiency in moving fluids with low viscosity. A study by Allied Market Research revealed that centrifugal pumps account for around 60% of the pump market. However, selecting the right pump can be challenging. Factors such as fluid characteristics, operating conditions, and required flow rates must be considered carefully.

Despite their utility, industrial pumps can pose challenges. Regular maintenance is required to ensure efficiency. Some industries report up to 30% of their energy consumption is due to inefficient pumping systems. This indicates a potential for significant cost savings if optimized correctly. Companies must reflect on their existing systems to improve efficiency and reduce waste.

Types of Industrial Pumps: Overview of Common Variants

Industrial pumps are essential for various applications in manufacturing and processing industries. They are designed to move fluids efficiently. There are several types of industrial pumps, each serving specific purposes.

Centrifugal pumps are one common type. They use rotational energy to move fluids. This pump works well for low-viscosity liquids. Positive displacement pumps, however, are another key variant. They move fluids by trapping a fixed amount and forcing it into the discharge pipe. These pumps are suitable for viscous materials.

When choosing a pump, consider your fluid’s properties. Temperature and viscosity matter. For thicker liquids, positive displacement pumps may be more effective. Tips: Always evaluate energy efficiency. An over-spec pump can result in energy waste. Regular maintenance is crucial too. Neglecting it can lead to unexpected failures. These factors greatly influence operational costs.

Additionally, think about installation space. Some pumps require specific arrangements for optimal performance. Tight spaces might limit your options. Understanding these details helps ensure you choose the right pump for your needs. Make informed decisions for better efficiency and reliability.

Types of Industrial Pumps - Common Variants

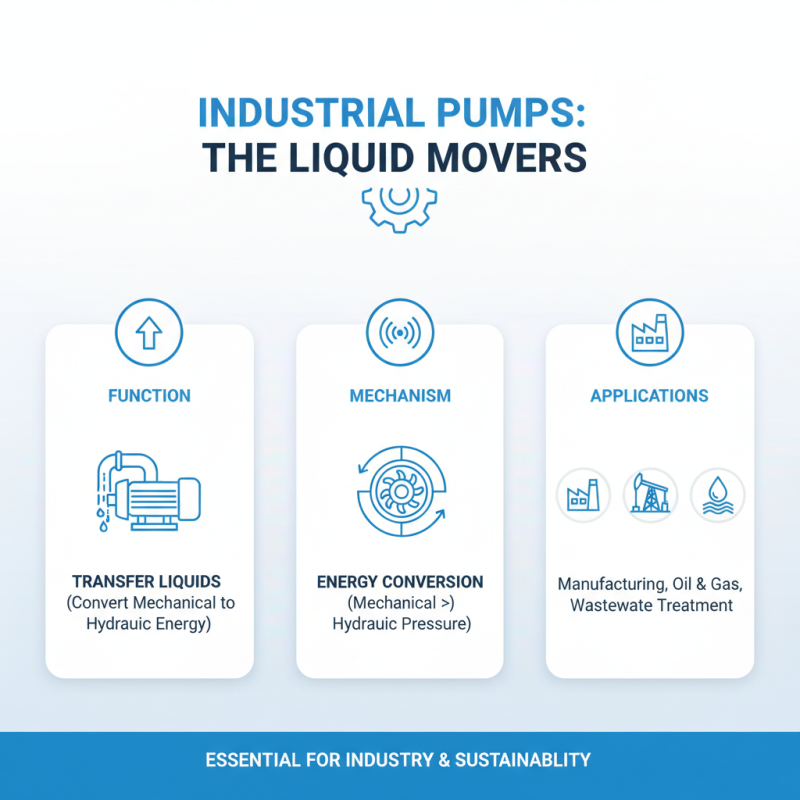

Principles of Operation: How Industrial Pumps Function Mechanically

Industrial pumps play a crucial role in various applications. They transfer liquids from one location to another. Generally, pumps convert mechanical energy into hydraulic energy. This process is essential in industries like manufacturing, oil and gas, and wastewater treatment.

The principles of operation rely on different mechanisms. Centrifugal pumps use a rotating impeller to increase fluid velocity. This motion creates suction at the inlet, drawing liquid into the pump. Positive displacement pumps, on the other hand, trap a fixed volume of liquid and force it out. Both types of pumps require precise construction to function effectively.

Mechanical issues can arise in any pump system. Wear and tear on components may lead to inefficiencies. Vibration or excessive noise can indicate potential problems. Regular maintenance is crucial to ensure optimal operation. Monitoring the condition of seals and bearings is necessary. Understanding how pumps work helps in troubleshooting and improving their lifespan.

Applications of Industrial Pumps in Various Industries and Sectors

Industrial pumps play a crucial role in many sectors. They are used for transferring liquids, slurries, and even gases. These pumps vary widely in design and capability. In the oil and gas industry, pumps transfer crude oil from extraction sites. They ensure smooth operations, but leaks can be problematic. Safety measures must always be implemented, as the stakes are high.

In the water treatment sector, industrial pumps help in purifying and distributing water. They push water through filtration systems, making it safe for consumption. However, not all pumps are suited for every task. Some struggle in high-pressure situations or with abrasive materials. This mismatch can lead to inefficiencies and costly downtime, which is a concern many operators face.

Manufacturing is another area where industrial pumps are essential. They move liquids needed in production processes. In food and beverage manufacturing, hygiene is vital. Any contamination can spoil products and harm consumers. Regular maintenance is needed, yet many facilities overlook this. The consequences can be severe, reminding us that attention to detail is always important.

Maintenance and Efficiency: Best Practices for Industrial Pump Longevity

Industrial pumps play a crucial role in various processes. Regular maintenance is key to ensuring their efficiency and longevity. A well-maintained pump operates smoothly and saves on energy costs. Neglect can lead to costly breakdowns and inefficiencies.

Tip: Inspect seals and gaskets regularly. This can prevent leaks and save energy. Even minor leaks can cause significant issues over time.

Another important aspect is to monitor vibration levels. Unusual vibrations can indicate misalignment or wear. Addressing these early can prevent major failures.

Tip: Keep a maintenance log. Documenting each service can help spot trends and recurring issues. Sometimes, the smallest details reveal the biggest problems.

Finally, proper lubrication is essential. Over-lubrication can be as damaging as under-lubrication. Finding a balance is not always easy. Regular checks are necessary to maintain optimal performance.

Related Posts

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

10 Essential Tips for Choosing the Right Pressure Pumps for Your Needs

-

Why is a Steam Condensate Return Pump Essential for Energy Efficiency?

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

Top 10 Small Centrifugal Pumps for Efficient Water Management in 2023

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023