Contact Us

What Are the Key Tips for Effective Condensate Return Tank Management?

The management of a condensate return tank is crucial for maintaining efficiency in steam systems. Condensate return tanks collect and recycle condensate, which saves energy and reduces water waste. Effective management ensures that these tanks operate optimally, supporting overall system reliability.

Proper maintenance of the condensate return tank is essential. Regular inspections help identify issues like leaks and corrosion. Monitoring temperature and pressure can prevent system failures. However, many overlook these steps. Neglecting proper care can lead to inefficient operation and costly repairs.

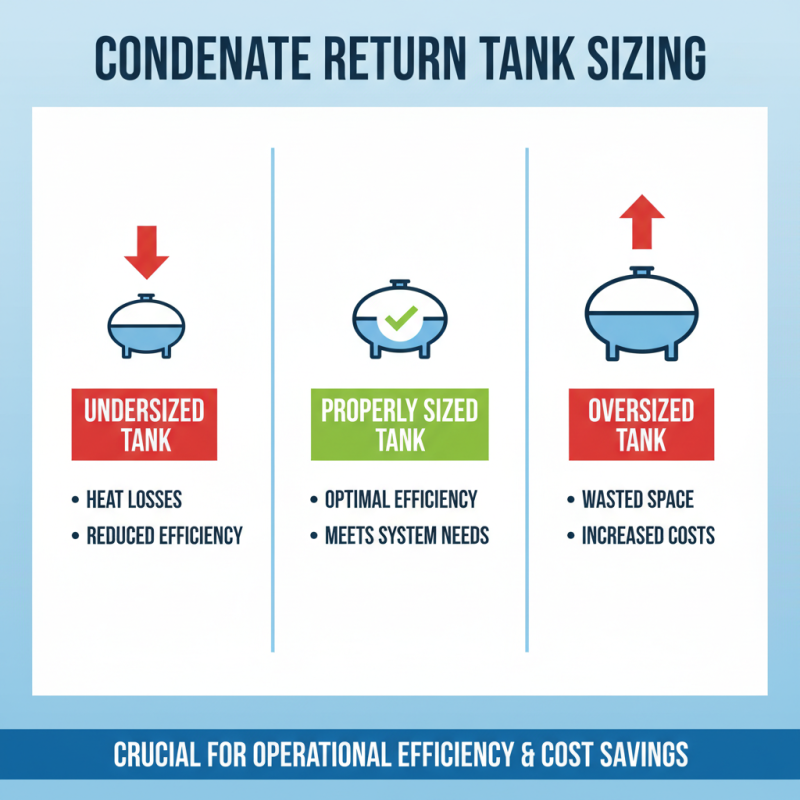

In managing a condensate return tank, proper sizing must also be considered. An under-sized tank can lead to issues with overflow, while an oversized tank may cause excessive heat loss. Balancing tank size with system demands is a challenge many face. Attention to these details matters significantly in achieving optimal tank management.

Key Considerations for Proper Sizing of Condensate Return Tanks

When managing condensate return tanks, proper sizing is crucial. The size affects efficiency and operational costs. Ideally, a tank should hold enough condensate to meet the system's needs. Reports suggest that undersized tanks can lead to heat losses. In contrast, oversized tanks waste space and resources.

Consider the flow rate. A tank should accommodate the peak condensate return. Typical industrial systems may require tanks capable of holding 300 to 500 gallons. A tank too small may cause frequent cycling, leading to pump wear. Too large? It may lead to slow condensate return times and potential contamination.

Operational flexibility is also key. If production changes, tank size should adapt. Regular assessments help identify if the existing capacity meets demands. Inefficiency in sizing could waste up to 20% of energy. This reality underscores the importance of ongoing evaluations. Can your system handle changes efficiently?

The Role of Condensate Quality in Effective Tank Management

Condensate quality plays a crucial role in tank management.

High-quality condensate can significantly enhance the efficiency of a system.

It reduces the risk of corrosion and improves

heat transfer. When the condensate is contaminated,

it can lead to potential operational issues. Managing impurities is vital. Regular inspections can help assess

condensate quality.

Monitoring parameters like pH and total dissolved solids is necessary.

Maintaining an optimal temperature is equally important. If the condensate is too hot

or cold, it may impact the tank’s performance. Regular sampling helps in

identifying unwanted substances. Engaging staff in training can ensure everyone understands the importance of

quality control.

Sometimes, tank management may overlook seemingly minor issues. A small leak or a tiny amount of rust can escalate.

Diligence in routine maintenance is essential. Even minor contaminants can lead to significant issues down the line.

Continuous reflection on practices can lead to better outcomes. In any tank management strategy,

quality should always remain the priority.

Monitoring and Maintaining Optimal Temperature Levels in Return Tanks

Maintaining optimal temperature levels in condensate return tanks is crucial. These tanks collect used steam condensate for reuse. When the temperature fluctuates, efficiency drops. The right temperature ensures effective recovery and minimizes energy loss.

Regular monitoring is vital. Utilize simple thermometers or advanced sensors for accurate readings. A quick glance can reveal significant issues. If temperatures climb too high, return water may lose its thermal energy. Cold water entering hot tanks can create thermal shock. This could damage the tank or connected systems.

Regular maintenance checks are necessary, but often overlooked. Periodic inspections should focus on insulation and leaks. Poor insulation can lead to unwanted heat loss. Leaks can cause temperature variations and inefficiencies. Neglecting these issues complicates management and increases operational costs. It's not just about collecting condensate, but also about ensuring it remains effective.

Common Challenges in Condensate Return Tank Operation and Solutions

Condensate return tanks play a vital role in steam systems. However, managing them often presents several challenges. One common issue is the accumulation of impurities. Many facilities report that up to 30% of condensate can be contaminated. This affects boiler efficiency and can lead to costly repairs. Regular monitoring and filtration can mitigate these problems, but implementation is often inconsistent.

Another challenge lies in pump failures. A study shows that around 25% of downtime in steam systems is due to pump-related issues. Poor maintenance practices contribute to this risk. Operators often overlook routine checks, leading to performance deterioration. Establishing a strict maintenance schedule could help. Yet, many facilities hesitate due to budget constraints.

Temperature fluctuations also pose problems. If the tank's temperature is too low, condensate can lose efficiency. Conversely, excessive heat may lead to pressure buildup. Regularly calibrating temperature sensors can prevent this. But, many operators don’t prioritize calibration. This negligence can result in unexpected failures. Addressing these challenges requires a proactive and committed approach, which is often lacking.

Key Tips for Effective Condensate Return Tank Management

This chart illustrates common challenges in condensate return tank management, highlighting the importance of water quality, regular maintenance, temperature control, pressure management, and energy efficiency in ensuring effective operation.

Impact of Regular Maintenance on Condensate Return Efficiency

Regular maintenance of condensate return tanks is crucial for optimal performance. The efficiency of these tanks can significantly affect steam systems. When maintenance is neglected, issues like corrosion and sludge buildup can emerge. These problems reduce overall system efficiency and lead to costly downtimes. Regular checks ensure that the tanks operate smoothly and efficiently.

Routine inspections can reveal hidden problems early on. Implementing a maintenance schedule helps keep things in check. Simple tasks like cleaning and monitoring water levels can prevent major breakdowns. However, some facilities overlook minor repairs. This oversight can lead to bigger issues later, causing potential revenue losses.

Effective management also involves staff training. Ensuring that team members understand maintenance protocols is vital. They should recognize symptoms of tank issues early. Nevertheless, even well-trained staff can miss signs if they are not diligent. Creating a culture of accountability can enhance overall performance. Continuous improvement in maintenance practices can yield far-reaching benefits.

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

Top 10 High Temperature Pump Tips You Need to Know for Efficient Operation