Contact Us

How to Maintain Boiler Water Quality for Optimal Efficiency?

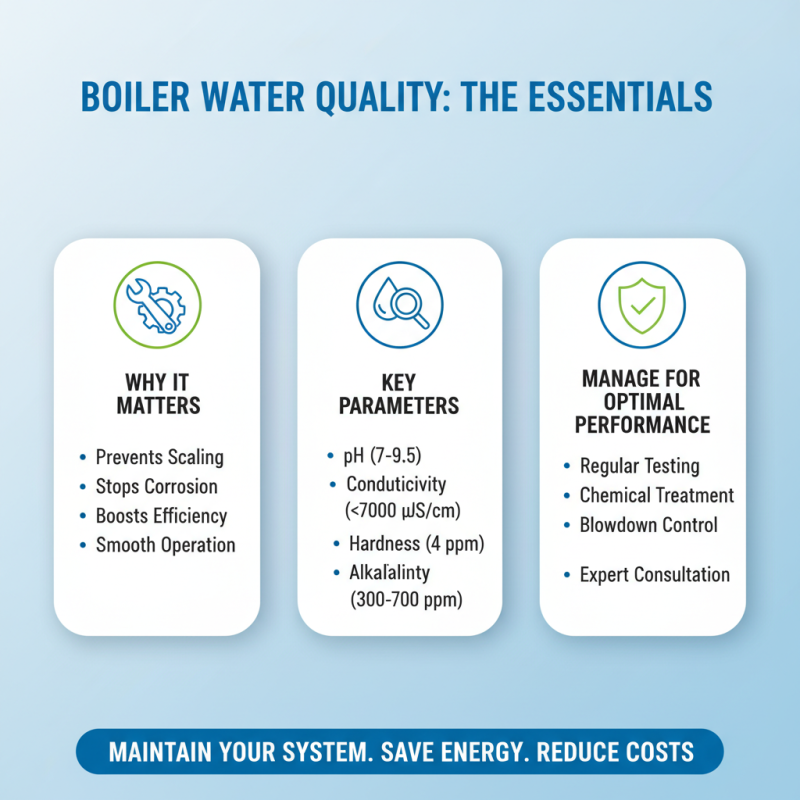

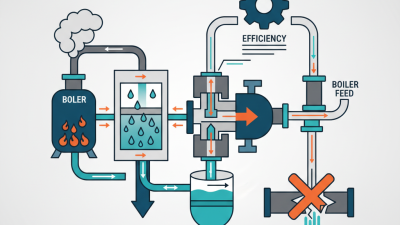

Maintaining boiler water quality is crucial for ensuring optimal efficiency in heating systems. Poor water quality can lead to serious issues. It can cause scale buildup, corrosion, and even system failures. Regular monitoring and treatment of boiler water are essential to avoid these problems.

Understanding the importance of boiler water quality can help in achieving maximum performance. Proper management of pH levels, alkalinity, and hardness is vital. Neglecting these factors can lead to unexpected costs and downtime. Each component plays a role in overall efficiency.

Inconsistent maintenance practices can result in long-term damage. It’s important to establish routines for testing and treating boiler water. Identifying the right chemicals and methods can be challenging but necessary. This article will delve into best practices and considerations for maintaining boiler water quality effectively.

Understanding Boiler Water Quality and Its Importance

Maintaining boiler water quality is critical. Poor water quality can lead to issues like scaling, corrosion, and reduced efficiency. Proper management ensures your boiler operates smoothly. Understanding the specific water quality parameters, like pH, conductivity, and hardness, is vital for optimal performance.

Tips: Regularly test the water chemistry. Look for signs of scaling. Adjust treatment accordingly. Monitoring helps prevent costly repairs.

Water impurities can significantly affect the boiler's lifespan. High levels of dissolved solids can cause foaming and carryover. Softening the water will reduce hardness. Regular blowdown practices also help control contaminants.

Tips: Implement a blowdown schedule. Ensure proper drains are functioning. This reduces the buildup of sediments. It’s crucial to ensure all equipment is in good condition. Inadequate maintenance leads to unexpected breakdowns.

Key Parameters for Assessing Boiler Water Quality

Maintaining boiler water quality is crucial for efficiency. Key parameters include pH, conductivity, and TDS. These indicators help ensure optimal performance and extend equipment life.

pH levels should ideally range between 10.5 and 11.5 to prevent corrosion. Low pH can lead to significant damage over time. Regular tests are essential. Measure pH frequently to ensure it’s within the optimal range.

Conductivity indicates the concentration of impurities in the water. High conductivity can lead to scale buildup. Aim to keep conductivity levels as low as possible. Monitor this regularly; it can vary based on water source and treatment methods. If you notice spikes, investigate the cause immediately.

Total dissolved solids reflect the quality of the water. High TDS levels can cause operational issues. Flushing the boiler system periodically helps manage TDS. Here’s a tip: consider implementing a continuous monitoring system. It provides real-time data and can alert you to potential problems before they escalate. Maintaining these parameters can streamline your operations.

Techniques for Testing and Monitoring Boiler Water

Maintaining boiler water quality is crucial for efficiency. Regular testing and monitoring ensure your system runs smoothly. You should check pH levels, conductivity, and dissolved oxygen. Neglecting these can lead to corrosion and scaling.

Tips for testing: Use reliable test kits for accurate results. Schedule testing at regular intervals. If readings deviate, investigate immediately. Remember, even a small leak can affect water quality.

Make a habit of logging results. This will help identify trends or recurring issues. A log can reveal underlying problems over time. If the data indicates consistent fluctuations, it’s worth a deeper look. Don’t ignore small changes; they can signal larger issues. Keeping an eye on water quality involves diligence.

Monitor chemical treatments closely. Over-treatment can be as harmful as under-treatment. Adjust according to test results. Engage with your maintenance team regularly. Their insights are invaluable. Overall, a consistent focus on testing leads to better boiler performance.

Best Practices for Treating Boiler Water and Preventing Issues

Maintaining boiler water quality is crucial for operational efficiency. Proper treatment keeps systems running smoothly. Many overlook monitoring pH levels. This can lead to severe corrosion and inefficiency. Regular testing should become a routine practice.

Adding chemicals to control hardness is essential. Hard water can result in scale buildup, wasting energy. It’s vital to manage oxygen levels, too. Dissolved oxygen leads to rust, damaging components over time. Imagine a small leak turning into a major repair. This oversight can be costly.

Regular blowdown prevents sludge accumulation. Sludge can reduce heat transfer efficiency. However, be careful not to overdo it, as excessive blowdown wastes water and energy. Implementing a comprehensive water treatment plan is a step many facilities ignore. A little attention goes a long way. Each decision can either enhance or diminish boiler performance. Prioritize water quality; the results will speak for themselves.

Regular Maintenance Strategies for Optimal Boiler Efficiency

Regular maintenance is crucial for optimal boiler efficiency. Poor water quality can reduce the lifespan of the boiler. A report from the American Society of Mechanical Engineers states that improper water treatment can result in up to a 20% decrease in boiler efficiency. This highlights the need for regular checks and proper water analysis.

Water hardness is a common issue. High levels of minerals can lead to scaling. This scale buildup can decrease heat transfer efficiency. Regular blowdown procedures help control concentrations of dissolved solids. The National Board of Boiler and Pressure Vessel Inspectors recommends performing blowdown at least once a week. Neglecting this can lead to costly repairs.

Regularly checking pH levels is also vital. A pH range of 10.5 to 11.5 is often ideal for boiler water. Deviations can corrode components. Monitoring alkalinity levels ensures that corrosion inhibitors function correctly. It’s crucial to note that maintaining optimal water quality is an ongoing process. Using automated monitoring systems can greatly assist in maintaining required parameters. However, reliance on technology should not replace human oversight. Always review data analytics carefully. Errors in reading can lead to serious operational issues.

Related Posts

-

Top 10 Effective Ways to Optimize Boiler Water Quality for Better Performance

-

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs

-

Top 10 Multistage Centrifugal Pump Benefits and Applications You Should Know

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

Top 10 High Temperature Pump Tips You Need to Know for Efficient Operation

-

What is a Steam Condensate Pump and How Does It Work?