Contact Us

Top 10 Multistage Centrifugal Pump Benefits and Applications You Should Know

In the world of fluid dynamics and engineering solutions, multistage centrifugal pumps stand out as pivotal components in various industrial applications. As noted by renowned pump expert Dr. Emily Carter, "The efficiency and versatility of multistage centrifugal pumps are unmatched, making them indispensable in many sectors." These pumps operate by employing multiple impellers to enhance the pressure and flow of liquids, which allows them to serve a wide range of purposes, from water supply systems to chemical processing.

Understanding the benefits and applications of multistage centrifugal pumps is essential for engineers and businesses looking to optimize their operations. They are particularly valued for their ability to maintain high efficiency while handling significant pressure differences, making them ideal for applications requiring the transportation of fluids over long distances. This article delves into the top ten benefits of these powerful pumps, highlighting their crucial role across various industries and emphasizing why they should be a focal point in modern engineering projects. With applications ranging from water treatment plants to irrigation systems, the multistage centrifugal pump continues to evolve, providing innovative solutions to meet contemporary challenges.

Top Advantages of Multistage Centrifugal Pumps in Fluid Dynamics

Multistage centrifugal pumps are crucial in various industrial applications due to their ability to manage multiple pressure stages, making them ideal for transporting fluids over long distances or to high elevations. According to the American Society of Mechanical Engineers (ASME), these pumps can achieve heads up to 4,500 feet or more, significantly outperforming single-stage pumps. This high efficiency is achieved by utilizing several impellers arranged in series, which increases the fluid pressure with each stage without requiring excessive energy consumption.

One of the most notable advantages of multistage centrifugal pumps in fluid dynamics is their adaptability to a wide range of applications. They are commonly used in water supply systems, boiler feed systems, and processes requiring high-pressure cleaning. A study presented by the Hydraulic Institute indicates that these pumps maintain reliable flow rates and can operate efficiently with varying fluid viscosities. Furthermore, advancements in materials and pump design have enhanced their durability, contributing to lower operational costs and reduced maintenance requirements over their lifecycle. The ability to handle different types of fluids, including corrosive and viscous materials, expands their utility across sectors such as oil and gas, agriculture, and chemical processing.

Key Applications of Multistage Centrifugal Pumps in Industrial Settings

Multistage centrifugal pumps play a critical role in various industrial applications due to their ability to generate high pressure and maintain flow over long distances. These pumps are particularly effective in systems where high head and low flow rates are required. One of the key applications of multistage centrifugal pumps is in water supply and distribution systems, where they are used to transport water from reservoirs to treatment plants and ultimately to consumers. Their efficiency in handling large volumes of water makes them indispensable in municipal water systems.

Another significant application of multistage centrifugal pumps is in the oil and gas industry. They are utilized for transporting hydrocarbons at different stages, from extraction to refining processes. These pumps can efficiently handle different fluids, including light and heavy oils, ensuring a steady flow even under varying pressure conditions. Additionally, in the power generation sector, multistage centrifugal pumps are crucial for boiler feedwater, providing the necessary pressure to move water through the system, thereby playing a vital role in maintaining the efficiency of power plants. Their versatility and reliability in these demanding applications highlight their importance in sustaining industrial operations.

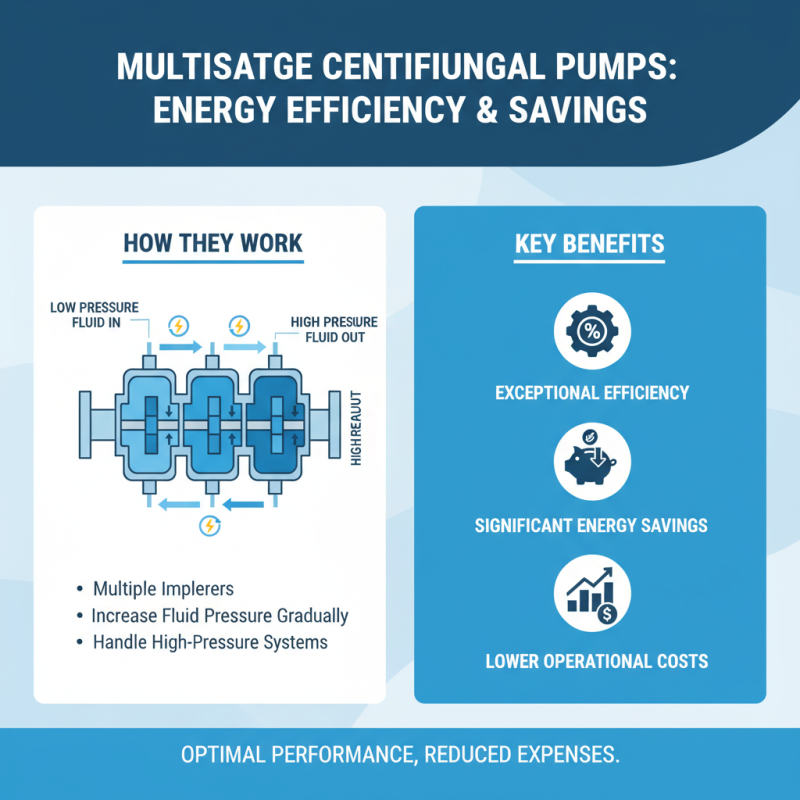

Efficiency and Energy Savings Offered by Multistage Centrifugal Pumps

Multistage centrifugal pumps are renowned for their exceptional efficiency and energy savings, making them a popular choice in various industrial applications. Unlike single-stage pumps, multistage pumps utilize multiple impellers to increase fluid pressure, allowing them to effectively handle high-pressure systems. This mechanism not only improves the overall efficiency of fluid transport but also reduces energy consumption significantly. As a result, businesses can achieve lower operational costs while maintaining optimal performance.

One of the key advantages of multistage centrifugal pumps is their adaptability across different applications, from water supply systems to chemical processing. The design of these pumps enables them to operate at varying flow rates and pressures, ensuring they meet the specific demands of different scenarios. This versatility contributes to substantial energy savings as they often operate more efficiently at varying loads compared to traditional pumping solutions.

**Tips:** When selecting a multistage centrifugal pump, consider the specific needs of your application to ensure maximum efficiency. It is advisable to analyze the required flow rate and pressure beforehand. Regular maintenance checks can also enhance performance and longevity, reducing energy wastage over time. Additionally, choosing pumps with a high-efficiency rating can further contribute to energy conservation in your operations.

Comparative Analysis: Multistage vs. Single-Stage Centrifugal Pumps

When evaluating pumps for various industrial applications, the comparison between multistage and single-stage centrifugal pumps becomes crucial for determining the most efficient solution. Multistage pumps, equipped with multiple impellers, excel in generating higher pressures and flow rates, making them suitable for applications requiring elevation of liquids over significant distances. According to a report by the Hydraulic Institute, multistage pumps can operate effectively at head levels exceeding 1,500 feet, while single-stage pumps typically max out at around 200-300 feet. This significant disparity makes multistage pumps a preferred choice in industries such as water supply, irrigation, and fire-fighting systems.

In terms of energy efficiency, multistage pumps demonstrate a superior ability to maintain performance across a range of operation levels. The American Society of Mechanical Engineers found that multistage designs can achieve efficiency ratings upwards of 85%, reducing energy consumption and operational costs. Conversely, single-stage pumps, although simpler and often more cost-effective for low-pressure applications, may lead to inefficiencies when tasked with high-pressure requirements. This divergence indicates that while single-stage pumps might suffice for simple applications, multistage pumps provide a crucial advantage where performance and reliability are paramount, particularly in demanding scenarios such as industrial processes and municipal water treatment systems.

Maintenance Best Practices for Optimal Performance of Multistage Pumps

Multistage centrifugal pumps are vital in various industries, known for their ability to efficiently move fluids at high pressures. For these pumps to maintain optimal performance, adherence to best maintenance practices is essential. Regular inspections should focus on key components such as bearings, seals, and impellers. According to a study by the Hydraulic Institute, up to 30% of pump failures are related to mechanical issues that could be identified during routine maintenance. This highlights the importance of a proactive maintenance schedule that can significantly extend the life of a multistage pump.

Another critical aspect of maintenance is monitoring the pump's operating conditions. Keeping track of system pressure, flow rates, and temperature can provide valuable insights into pump performance. Data from the Pump Industry Europe report indicates that 15% of operational inefficiencies can be traced back to improper operating conditions, which directly affects energy consumption and costs. Implementing a comprehensive monitoring system enables engineers to detect anomalies early and address issues before they evolve into significant problems. By following these best practices, industries can ensure that their multistage centrifugal pumps operate at peak efficiency while minimizing downtime and repair costs.

Related Posts

-

7 Essential Tips for Choosing the Right Vertical Centrifugal Pump for Your Needs

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

Understanding the Importance of Boiler Feed Tanks in Maximizing Efficiency and Reducing Costs

-

How to Choose the Right Liquid Propane Pump for Your Needs