Contact Us

What is a Steam Condensate Pump and How Does It Work?

Steam condensate pumps play a crucial role in industrial processes. According to John Smith, a leading expert in the field, “A steam condensate pump is essential for efficiency.” These pumps handle the condensation of steam. They help prevent water accumulation in systems.

In industries, steam is widely used for heating. When steam cools, it turns back into water, known as condensate. Without proper management, this condensate can cause inefficiencies. Sometimes, systems can become overwhelmed. This is where the steam condensate pump steps in.

However, many facilities overlook its importance. They may not fully understand the challenges involved. Proper installation and maintenance are vital. Neglecting these aspects can lead to costly downtime. Therefore, awareness of steam condensate pumps is critical for any operation relying on steam.

What is a Steam Condensate Pump and Its Role in Thermodynamics?

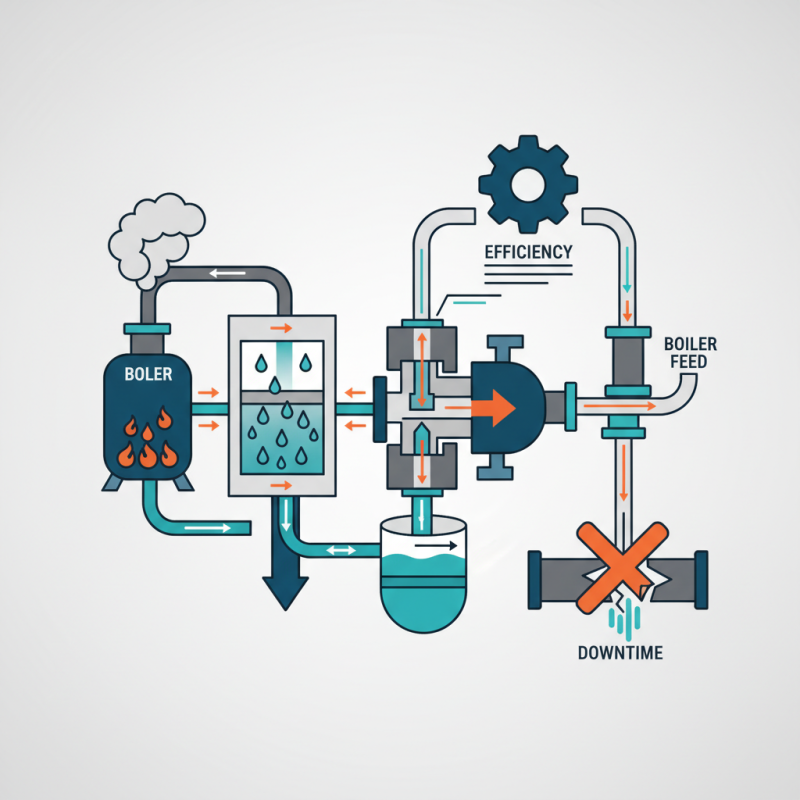

A steam condensate pump is essential in thermodynamic systems. It efficiently removes condensate, ensuring optimal heat exchange. When steam cools, it turns back into water, creating condensate. This process is common in power plants and industrial applications.

The condensate must be recycled for efficiency. A pump moves the condensate back to the boiler. This reduces energy waste and lowers operational costs. However, improper pump selection can lead to failures. Regular maintenance is crucial to ensure peak performance.

In practice, factors like temperature and pressure can affect pump efficiency. Sometimes, the pump may struggle with high viscosity fluids. This can lead to unanticipated downtime and costly repairs. Choosing the right materials for the pump becomes vital in such situations. Balancing efficiency and durability is not always straightforward, but it matters greatly for the system's success.

Key Differences Between Steam Condensate Pumps and Traditional Pumps

Steam condensate pumps play a crucial role in industrial applications. They are designed to manage steam that has condensed back into liquid water. This process is essential for maintaining efficiency in steam systems. Unlike traditional pumps, steam condensate pumps deal specifically with condensate. They ensure the safe removal of this liquid, which can be detrimental if left unchecked.

The working mechanism of a steam condensate pump differs significantly from that of a traditional pump. Traditional pumps generally move liquids with lower vapor pressures. Condensate pumps, however, can handle the unique challenges posed by steam. According to industry reports, steam condensate pumps often have a higher capacity for pressure. They can handle pressures up to 200 PSI or more. This capability is vital in maintaining steam system efficiency.

There are significant efficiency differences as well. A steam condensate pump can recover energy that would be lost with traditional pumps. This recovery can improve plant efficiency by up to 30%, according to recent studies. However, improper selection and sizing of these pumps can lead to performance issues. It's crucial to understand the specific needs of your system. Mistakes in this area can result in increased wear and degradation of pump components.

The Working Principle of a Steam Condensate Pump Explained

A steam condensate pump plays a crucial role in industrial applications. Understanding its working principle can significantly enhance efficiency. The pump removes condensate formed from steam cooling, bringing it back into the steam system. This process maintains optimal thermal efficiency and conserves water and energy.

When steam condenses, it creates water that needs to be removed. The condensate pump uses a motor-driven impeller to transport this water. As water enters the pump, it lifts and moves the condensate to the drainage system. This prevents water accumulation and pressure build-up in the system. According to industry reports, effective condensate management can save energy costs by up to 30%.

**Tips:** Regularly inspect your condensate pump for blockages. Clean it every six months to ensure optimal performance. Avoid neglecting this maintenance, as it can lead to inefficiencies.

Understanding the nuances of a steam condensate pump is essential. Not every installation operates perfectly. Some systems may require additional modifications to improve flow rates. Monitoring performance regularly helps identify potential issues early on. Always seek expert advice for complicated installations. Ain’t it easy to overlook what seems simple?

Steam Condensate Pump Performance Data

This chart illustrates the performance of steam condensate pumps based on varying flow rates and power consumption levels. The data demonstrates how pump efficiency can be impacted by flow rate changes.

Importance of Energy Efficiency in Steam Condensate Pump Operations

Energy efficiency in steam condensate pump operations plays a crucial role. A steam condensate pump recycles water produced when steam cools and condenses. This process is essential for maintaining optimal thermal efficiency in industrial systems. When pumps operate efficiently, energy consumption decreases significantly. This leads to lower operational costs, which benefits businesses in the long run.

Many plants overlook the importance of maintenance. Regular checks can reveal inefficiencies. A worn-out pump may consume more energy than necessary. Propeller speed can fluctuate, reducing overall performance. Simple adjustments or repairs can enhance efficiency.

Moreover, the quality of condensate is often disregarded. Impurities can cause corrosion, affecting pump lifespan. Workers may not always notice these issues until problems arise. Training is vital for personnel to identify early signs of inefficiency. Regular monitoring can help maintain an energy-efficient system. Failing to address these aspects may lead to lost opportunities for savings.

Common Applications and Industries Utilizing Steam Condensate Pumps

Steam condensate pumps play a critical role in various industries. These pumps efficiently remove condensate from steam systems, ensuring optimal performance. Applications range from power generation to food processing. In power plants, they help manage steam after it has done work. In food processing, they support heating systems and maintain equipment efficiency.

Chemical companies also benefit from steam condensate pumps. They create the right temperatures for reactions, ensuring product quality. However, operators often face challenges. Poor maintenance can lead to inefficiencies. Blockages and leaks in the pump can disrupt processes. Regular inspections and proper training are needed to prevent these issues.

In pharmaceuticals, maintaining a sterile environment is vital. Steam condensate pumps help manage heat in cleanrooms. Without them, temperature fluctuations can compromise product safety. Each industry has unique needs, but the essence remains the same. Effective condensate management is crucial for maintaining productivity and quality across sectors.

What is a Steam Condensate Pump and How Does It Work? - Common Applications and Industries Utilizing Steam Condensate Pumps

| Dimension | Value | Description |

|---|---|---|

| Flow Rate | 500 - 2000 GPH | Typical flow rate range for industrial steam condensate pumps. |

| Pump Type | Centrifugal, Positive Displacement | Common types of pumps used for condensate removal. |

| Temperature | Up to 230°C | Maximum operating temperature for effective condensate pumping. |

| Applications | Food Processing, Power Generation, Chemical Industry | Industries that use steam condensate pumps extensively. |

| Efficiency | 85% - 95% | Typical efficiency range of steam condensate pumps. |

| Material | Stainless Steel, Cast Iron | Common materials used for manufacturing condensate pumps. |

Related Posts

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

How to Choose and Maintain a Boiler Condensate Pump for Optimal Performance

-

What Are the Key Tips for Effective Condensate Return Tank Management?

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023