Contact Us

Why is a Steam Condensate Return Pump Essential for Energy Efficiency?

Energy efficiency is crucial for modern industries. A steam condensate return pump plays a key role in achieving this goal. By effectively returning condensate to the boiler, these pumps help save energy and reduce operational costs.

Steam systems produce heat for various processes. However, when steam condenses, valuable energy can be lost if not properly managed. A well-functioning steam condensate return pump captures this condensate. It ensures that heat energy is reused rather than wasted. This not only enhances overall efficiency but also minimizes water consumption.

Despite the benefits, some systems struggle with pump maintenance. Issues such as wear and clogging can hinder performance. Regular checks are essential to ensure the steam condensate return pump operates efficiently. Investing in proper maintenance is crucial for maximizing energy savings and maintaining productivity.

Importance of Steam Condensate Return in Industrial Processes

Steam condensate return systems are critical in industrial processes. They play a vital role in saving energy and improving efficiency. According to a report by the U.S. Department of Energy, returning steam condensate can lead to energy savings of up to 30%. This is significant for any plant looking to reduce operational costs.

The condensate that returns is nearly pure water. This water is hot, often at temperatures above 200°F. By recycling this condensate, facilities reduce the need for fresh water. The International Energy Agency estimates that using condensate return systems can cut down water usage by as much as 50%. However, not all facilities effectively manage their condensate. Many waste energy by allowing it to escape through venting.

But challenges exist. Some facilities face high maintenance costs. Additionally, old piping systems may corrode or leak. These issues can lead to energy losses. Ensuring the integrity of the condensate return system is crucial. Regular inspections and preventive measures can help sustain its effectiveness and efficiency. Without proper management, the benefits of condensate return can be lost.

How Steam Condensate Return Pumps Optimize Energy Efficiency

Steam condensate return pumps play a crucial role in energy efficiency. They recycle steam condensate back into the boiler system. This reduces the need for fresh water and optimizes energy use. By returning condensate, facilities save on heating costs and minimize waste.

When condensate is returned, it retains a significant amount of energy. This energy can be reused. Facilities avoid the energy lost during the cooling process. Many overlook this aspect. They might not realize the potential savings. Regular maintenance ensures efficiency. Dirty pumps or clogged lines can hinder performance.

Tips: Regularly inspect and clean your pump systems to maintain efficiency. Consider monitoring systems for real-time data. This can help identify inefficiencies quickly. A small step can lead to significant savings in the long run.

Key Benefits of Implementing a Steam Condensate Return System

Implementing a steam condensate return system offers several key benefits that enhance energy efficiency.

According to the U.S. Department of Energy, returning steam condensate can save up to 20% on energy costs.

This is particularly important in industrial settings where steam systems are prevalent. By capturing and reusing heat, facilities reduce their overall fuel consumption.

Every pound of condensate returned can save one gallon of water and over 1,000 BTUs of energy.

Additionally, reducing water and energy usage directly benefits the environment. Studies have shown that efficient condensate systems can lead to lower greenhouse gas emissions.

However, not all systems operate effectively. Poorly maintained condensate return pumps can create bottlenecks, causing steam to escape and energy loss.

Regular maintenance and monitoring are essential to ensure these systems function efficiently.

Moreover, steam condensate return systems reduce the need for fresh water supply. In areas where water scarcity is a concern, this reduction is extremely valuable.

It can also minimize wastewater treatment costs. Yet, many industries overlook this potential.

Failing to adopt best practices in steam management can lead to inefficiencies that impact the bottom line.

More awareness is needed to fully leverage the advantages of a well-designed condensate return system.

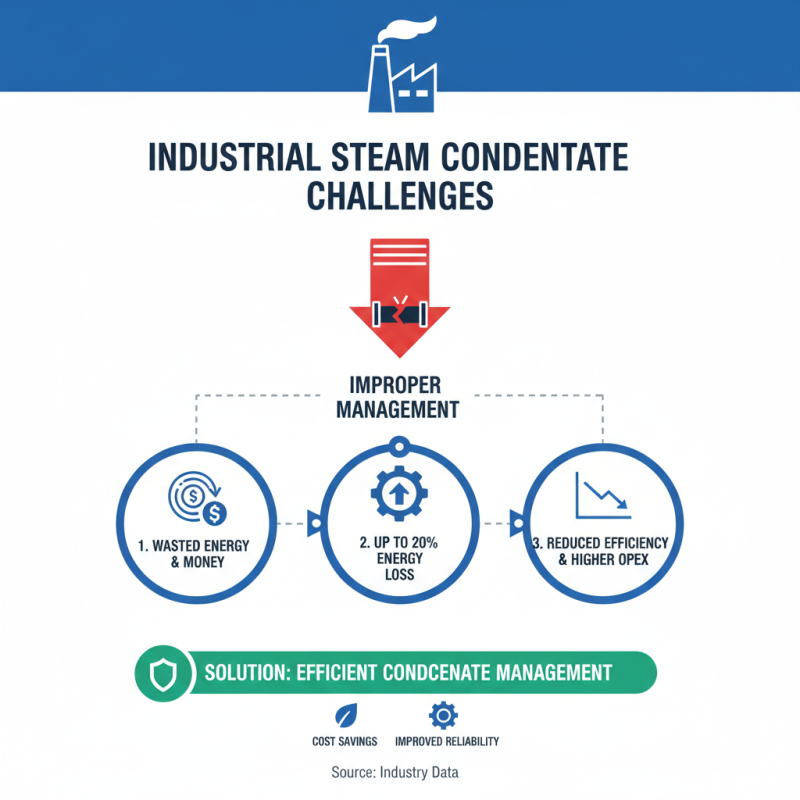

Challenges in Steam Condensate Management and Their Solutions

Steam condensate management poses significant challenges in industrial settings. Lost steam represents not just wasted energy but also increases costs. According to industry data, improper management can lead to an energy loss of up to 20% in some facilities. This loss heavily impacts overall efficiency and operational expenses.

Condensate return systems are often insufficiently maintained. Clogged pipes and ineffective pumps exacerbate these issues. Regular inspections are crucial, yet many facilities overlook them. Reports indicate that nearly 30% of plants experience problems with condensate recovery. This highlights the need for improved management practices.

Effective solutions exist to mitigate these challenges. Upgrading to advanced steam condensate return pumps improves efficiency. Implementing better tracking systems can also help monitor condensate quality and flow. These adjustments not only save energy but also prolong equipment lifespan. Despite the known benefits, the transition requires careful planning and investment. Adapting to these solutions can be daunting but ultimately necessary for sustainable operations.

Best Practices for Maintaining Steam Condensate Return Pumps

Maintaining steam condensate return pumps is crucial for optimizing energy efficiency. Regular checks can prevent costly leaks. Inspect seals and gaskets for wear. Even minor leaks can waste energy and increase costs. Keeping the system tight helps maintain steam pressure.

Cleaning filters is another key practice. Blocked filters can restrict flow. This leads to inefficiency in steam recovery. An overlooked filter can severely impact overall performance. Also, ensure all connections are tight. Loose fittings can create unwanted air pockets. These disrupt the condensation process.

Lastly, monitoring pump operation continuously is essential. Listen for unusual sounds. Vibrations may signal a problem. Timely intervention can save significant repair costs later. Ignoring minor issues often leads to major failures. Staying vigilant is the essence of effective maintenance.

Related Posts

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

Understanding the Efficiency of High Pressure Centrifugal Pumps in Industrial Applications

-

2025 How to Choose the Right Boiler Feed Tank for Your Needs

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

Top 10 Turbine Pump Types for Efficient Water Management Systems

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications