Contact Us

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

In the ever-evolving landscape of HVAC systems, ensuring optimal efficiency and performance is paramount. Central to this endeavor is the condensate pump, a critical component that facilitates the removal of condensate produced during the cooling process. According to a recent report by MarketsandMarkets, the global condensate pump market is projected to reach $2.13 billion by 2026, growing at a CAGR of 4.6% from 2021. This growth is indicative of the increasing demand for efficient HVAC solutions that not only enhance indoor air quality but also reduce energy consumption.

As HVAC systems become more sophisticated, the need for reliable condensate pumps has never been more pronounced. These pumps not only manage excess moisture but also prevent potential damage to mechanical systems and enhance overall operational efficiency. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) emphasizes that proper drainage is essential for maintaining optimal humidity levels, thereby prolonging the lifespan of HVAC equipment. This article delves into the top 10 condensate pumps available in 2023, highlighting their efficiency, reliability, and technological advancements to help professionals make informed decisions in enhancing their HVAC systems.

Essential Features to Consider When Choosing Condensate Pumps for HVAC Systems

When selecting a condensate pump for HVAC systems, several essential features should be considered to ensure optimal performance and efficiency. First, look for a pump with a high flow rate that can handle the expected condensate load. This feature ensures that the pump can quickly remove any excess water, preventing overflow and reducing the risk of damage to your HVAC system.

Another critical aspect is the pump's noise level. Many homeowners prefer quiet operation, especially in residential settings. Therefore, choosing a pump designed for low noise levels can greatly enhance comfort in your living space. Additionally, consider the durability of the pump materials; pumps made from corrosion-resistant materials will ensure a longer lifespan and reliable operation.

**Tips:** Pay attention to the size and capacity of the condensate pump in relation to your HVAC system's requirements. A pump that is too small may struggle to keep up, while one that is oversized could result in unnecessary energy usage. Moreover, check for features like built-in alarms or automatic shut-offs that can help alert you to issues before they escalate, saving you time and money in the long run.

Top 10 Condensate Pumps Efficiency Ratings (2023)

Top Brands of Condensate Pumps on the Market in 2023

In 2023, the market for condensate pumps has been dominated by several top brands known for their reliability and efficiency in HVAC systems. One of the standout names is Little Giant, recognized for its robust construction and innovative designs that cater to various applications. Their pumps are engineered with advanced features, including automatic shut-off and quiet operation, making them a preferred choice for both residential and commercial setups.

Another notable brand is Zoeller, which has built a reputation for producing high-quality condensate pumps that excel in performance and durability. Zoeller's offerings are characterized by their ability to handle high volumes of condensate while providing exceptional energy efficiency. Their commitment to manufacturing excellence is evident in the longevity of their products, which is a significant factor for HVAC professionals.

Finally, Wayne Pumps continues to be a major player in the market, with a focus on user-friendly designs and easy installation. Their condensate pumps are designed to minimize maintenance needs, appealing to both installers and end-users. With these top brands leading the way, HVAC systems can operate more effectively while ensuring that condensate is managed safely and efficiently.

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

| Model | Max Flow Rate (GPH) | Max Head (Feet) | Power (W) | Tank Capacity (Gallons) | Weight (lbs) |

|---|---|---|---|---|---|

| Model A | 50 | 20 | 150 | 0.5 | 5 |

| Model B | 45 | 18 | 120 | 0.5 | 6 |

| Model C | 55 | 22 | 160 | 0.6 | 7 |

| Model D | 60 | 25 | 180 | 0.7 | 8 |

| Model E | 40 | 15 | 100 | 0.4 | 4 |

| Model F | 70 | 30 | 200 | 0.8 | 9 |

| Model G | 75 | 28 | 210 | 1.0 | 10 |

| Model H | 65 | 24 | 190 | 0.9 | 9 |

| Model I | 80 | 32 | 220 | 1.2 | 11 |

| Model J | 85 | 35 | 230 | 1.5 | 12 |

Comparative Analysis of High-Efficiency Condensate Pumps

In the rapidly evolving HVAC industry, the selection of high-efficiency condensate pumps is paramount for optimizing system performance and energy efficiency. According to a report from the U.S. Department of Energy (DOE), the right condensate pump can potentially reduce energy consumption by up to 30% when integrated with modern HVAC systems. This is especially critical as buildings shift towards better energy management practices, and energy efficiency regulations become more stringent.

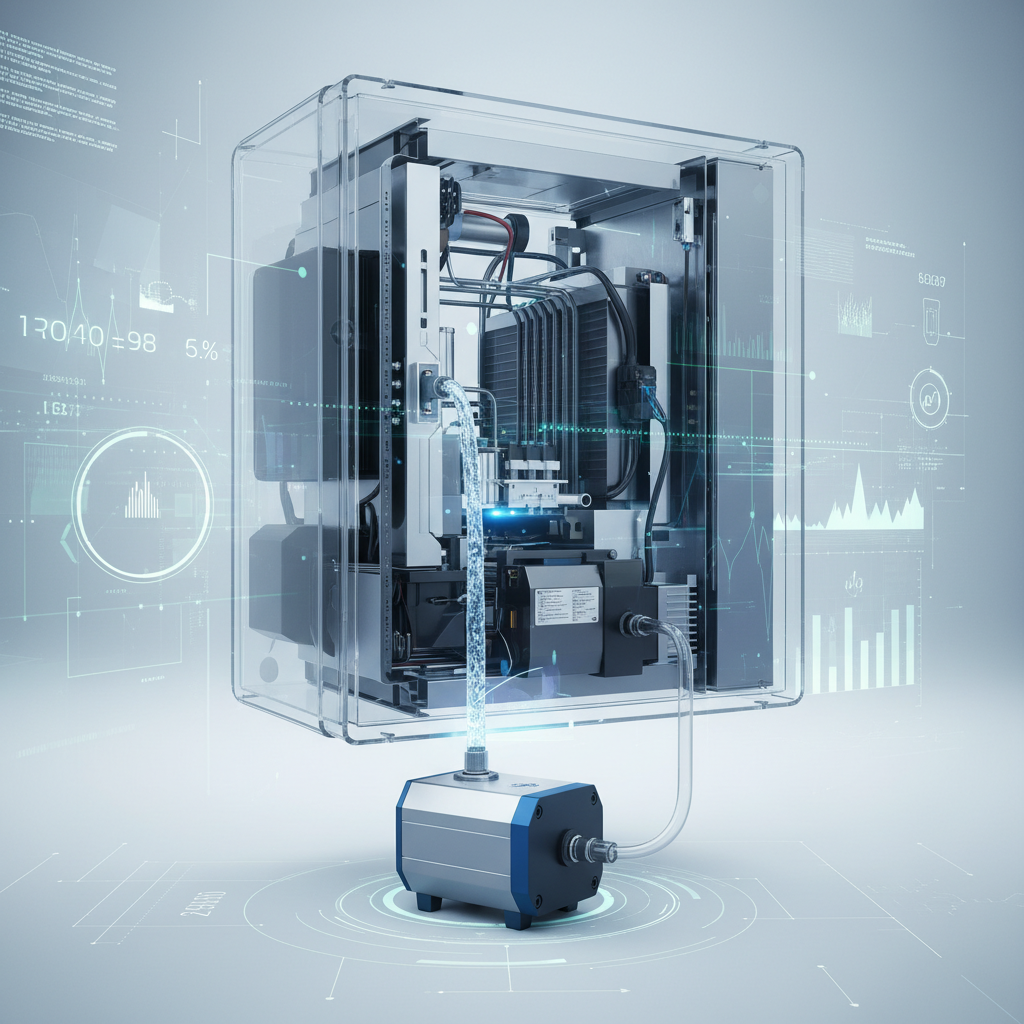

When analyzing models available in 2023, key performance metrics such as flow rate, head pressure, and motor efficiency play crucial roles. Recent comparative studies have demonstrated that the latest pump designs incorporate advanced features like variable speed technology and smart control systems. These innovations not only enhance operational efficiency but also provide real-time monitoring capabilities, allowing for better maintenance and reduced downtime. The industry’s shift towards eco-friendly refrigerants and renewable energy sources further emphasizes the importance of selecting condensate pumps that align with these sustainability goals, reinforcing the necessity for thorough comparative analysis before making a purchase decision.

Maintenance Tips to Maximize the Lifespan of Your Condensate Pump

Maintaining your condensate pump is crucial for ensuring the efficiency and longevity of your HVAC system. According to a report by the Air Conditioning Contractors of America (ACCA), regular maintenance can extend the lifespan of HVAC system components by up to 15 years. To maximize the durability of your condensate pump, it’s important to adhere to a proactive maintenance routine.

One effective tip is to regularly check and clean the pump's float switch, which is essential for detecting the water level. Any clogs or debris can lead to inefficient operation or complete failure. Additionally, inspecting the drain lines for blockages will ensure uninterrupted flow, as nearly 40% of condensate pump failures are attributed to blocked drain lines, as noted by the American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE).

Furthermore, consider testing your pump quarterly. This includes running the system and ensuring the pump activates and properly removes water. Regular checks not only assure reliability but can save on costly repairs down the line, as noted in a study by the National Institute of Standards and Technology (NIST), which states that preventive maintenance can reduce operational costs by up to 30%.

Expert Recommendations for Troubleshooting Common Condensate Pump Issues

When it comes to HVAC systems, condensate pumps play a crucial role in removing excess water that is produced during the cooling process. However, issues can arise, leading to inefficiencies or even system failures. One common problem is clogging, often caused by debris or algae in the condensate line. Regular maintenance, including cleaning the pump and the drainage lines, can help prevent blockages and keep your system running smoothly.

Another frequent issue is mechanical failure, which can stem from worn-out components or poor installation. If the pump is making unusual noises or fails to activate, it’s essential to investigate further. Checking the power supply and ensuring that the float switch is operational are good starting points. For those experiencing recurring issues, consulting a professional HVAC technician might be the best way to diagnose deeper electrical or mechanical problems, ensuring long-term reliability and efficiency for your HVAC system.

Related Posts

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs

-

What is a High Pressure Water Pump and How Does It Work