Contact Us

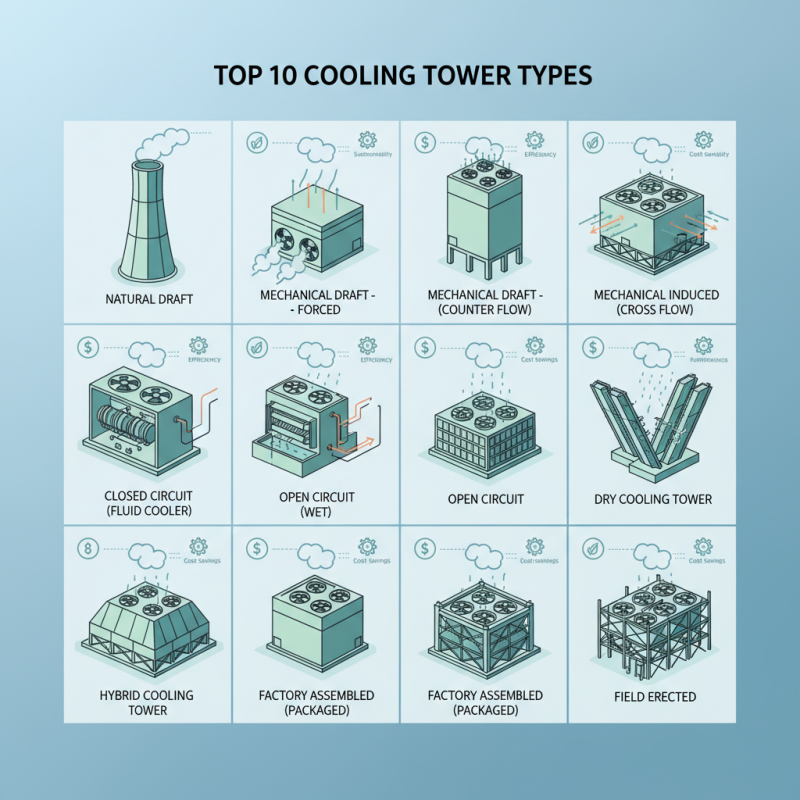

Top 10 Cooling Tower Types and Their Benefits Explained?

cooling towers play a critical role in various industries, offering essential cooling solutions. The American Society of Heating, Refrigerating and Air-Conditioning Engineers (ASHRAE) reports that effective cooling can improve efficiency by up to 30%. As companies strive for sustainability, selecting the right type of cooling tower becomes vital.

Renowned expert Dr. Emily Foster states, “Understanding different cooling tower types can lead to significant operational savings.” In the evolving landscape of energy consumption, choosing a cooling tower is not just about performance. It’s also about navigating costs, maintenance, and environmental impact. The variety of available options means decisions can be overwhelming.

Each cooling tower type presents unique advantages and disadvantages. Factors such as geographical location and application directly influence efficacy. The industry continues to adapt, highlighting the need for informed choices. Rushing the selection process can lead to inefficiencies. Exploring the top ten types offers valuable insights into making smarter decisions for long-term benefits.

Types of Cooling Towers and Their Fundamental Functions

Cooling towers play a vital role in industrial processes and HVAC systems. They help maintain optimal temperatures by dissipating excess heat. There are various types of cooling towers, each serving specific needs.

Open cooling towers are commonly used. They expose water to air directly, which enhances cooling efficiency. However, they can be prone to contamination if not properly maintained. Closed cooling towers, on the other hand, keep water sealed, reducing the risk of impurities. But, they often require more energy to operate effectively.

Cooling towers also vary in design and function. For instance, evaporative towers rely on water evaporation for cooling. This method can be highly efficient, but it may raise water consumption concerns. Dry cooling towers use air alone, which minimizes water usage but may struggle in very hot conditions. Each type has its pros and cons, making choices complex. Understanding these differences is essential for effective cooling solutions.

Natural Draft Cooling Towers: Mechanism and Advantages

Natural Draft Cooling Towers are a fascinating technology. They rely on natural convection to operate. Instead of using fans, these towers utilize temperature differences in air. Warm air rises, creating a draft. This draft pulls cooler air from the surroundings. It’s a simple yet effective mechanism.

The advantages of Natural Draft Cooling Towers are numerous. They are energy efficient because they don't require electrical power for fans. Maintenance can also be easier, as there are fewer mechanical parts. However, their size can be a drawback. They often need more space than other types. This can limit their use in certain areas, especially urban locations.

These towers can also face challenges due to environmental factors. For example, high ambient temperatures can affect performance. If the external environment is too warm, efficiency decreases. It’s essential to consider these factors in design and operation. Understanding the balance between benefits and limitations is crucial for optimal use.

Mechanical Draft Cooling Towers: Types and Their Applications

Mechanical draft cooling towers are widely used in various industries. They rely on mechanical fans to enhance air circulation. This method improves efficiency in dissipating heat compared to natural draft towers. The design generally features a tower structure with fill media that maximizes heat exchange surface area.

There are two main types: induced draft and forced draft cooling towers. Induced draft towers pull ambient air through the tower using fans located at the top. This configuration creates strong upward air movement. In contrast, forced draft towers push air into the system via fans at the base. Each type has its specific applications, depending on the operational requirements and space constraints.

While mechanical draft cooling towers are efficient, they are not without challenges. Noise from the fans can be disruptive, and mechanical parts require regular maintenance. Users must be vigilant about water treatments to prevent fouling, which can impact performance. These factors may require thoughtful consideration before a purchase or installation.

Crossflow vs. Counterflow Cooling Towers: Key Differences Explained

Cooling towers play a critical role in industrial processes. Two main types are crossflow and counterflow cooling towers. They have distinct designs and performance features.

Crossflow cooling towers allow water to flow horizontally across the airflow. This design promotes efficient heat transfer. According to industry reports, these towers generally utilize less energy than their counterparts. Their configuration also enables easier maintenance since components are more accessible. However, they can occupy larger spaces and may not be ideal for all facilities.

On the other hand, counterflow cooling towers have a vertical design. Water flows downward while air ascends. This design typically results in higher heat exchange efficiency. Yet, they are often more complex to maintain than crossflow towers. The choice between these types depends significantly on specific operational demands. Reports indicate that improper selection can lead to inefficiencies, impacting energy consumption and maintenance costs. Understanding the differences helps in making informed decisions.

Benefits of Using Cooling Towers in Industrial Applications

Cooling towers play a crucial role in various industrial applications. They help remove excess heat from processes, ensuring equipment operates efficiently. With rising energy costs, efficient cooling is more important than ever. Different types of cooling towers offer unique benefits tailored to specific needs.

Crossflow and counterflow cooling towers are popular choices. Crossflow designs allow air to flow horizontally, facilitating better heat exchange. This can maximize cooling efficiency in certain environments. On the other hand, counterflow models push air vertically through the water, enhancing performance in smaller footprints. Choosing the right type can lead to significant energy savings.

Integrating cooling towers can improve system reliability. They help prevent overheating, which can lead to equipment failure. However, not all cooling towers are created equal. Each has its strengths and weaknesses. Understanding these nuances is essential for optimizing industrial systems. Regular maintenance is also necessary to ensure peak performance. Over time, efficiency can diminish if not monitored closely.

Top 10 Cooling Tower Types and Their Benefits Explained

| Cooling Tower Type | Description | Benefits |

|---|---|---|

| Natural Draft | Relies on natural convection for air movement. | Low energy consumption, minimal maintenance. |

| Mechanical Draft | Uses fans to drive air through the tower. | High efficiency, adaptable size and capacity. |

| Crossflow | Air flows perpendicular to water flow. | Compact design, reduced water treatment needs. |

| Counterflow | Air flows in the opposite direction of water flow. | Efficient heat exchange, versatile applications. |

| Closed Circuit | Water is circulated in a closed loop. | Reduced water loss, better protection from contamination. |

| Open Circuit | Direct contact between air and water. | Effective cooling, simple design. |

| Hybrid | Combines dry and wet cooling methods. | Versatile operation in varying weather conditions. |

| Plastic Fill | Utilizes plastic media for heat exchange. | Lightweight, resistant to corrosion. |

| Wooden Tower | Traditional type using wood for construction. | Natural aesthetics, good thermal performance. |

| Steel Tower | Constructed from steel, often coated. | High durability, withstands harsh conditions. |