Contact Us

Top 10 Small Centrifugal Pumps for Efficient Water Management in 2023

In the realm of water management, the significance of efficient pumping systems cannot be overstated. According to recent industry reports, the global demand for such solutions has surged, driven by increasing urbanization and a growing need for sustainable water use. Among these solutions, the small centrifugal pump has gained considerable attention due to its versatility and effectiveness in various applications, including irrigation, wastewater management, and building services. These compact yet powerful pumps offer a range of capacities and efficiencies, making them ideal for both residential and commercial settings.

As water scarcity becomes an increasingly pressing issue, the role of small centrifugal pumps in optimizing water distribution systems is pivotal. The flexibility and energy efficiency of these pumps not only contribute to lower operational costs but also align with environmental sustainability goals. Recent studies indicate that implementing advanced small centrifugal pumps can lead to energy savings of up to 30%, further enhancing their appeal in various industrial and agricultural sectors. This introduction sets the stage for a comprehensive overview of the top 10 small centrifugal pumps for efficient water management in 2023, showcasing how these innovative solutions can effectively meet the challenges of modern water demands.

Overview of Small Centrifugal Pumps in Water Management

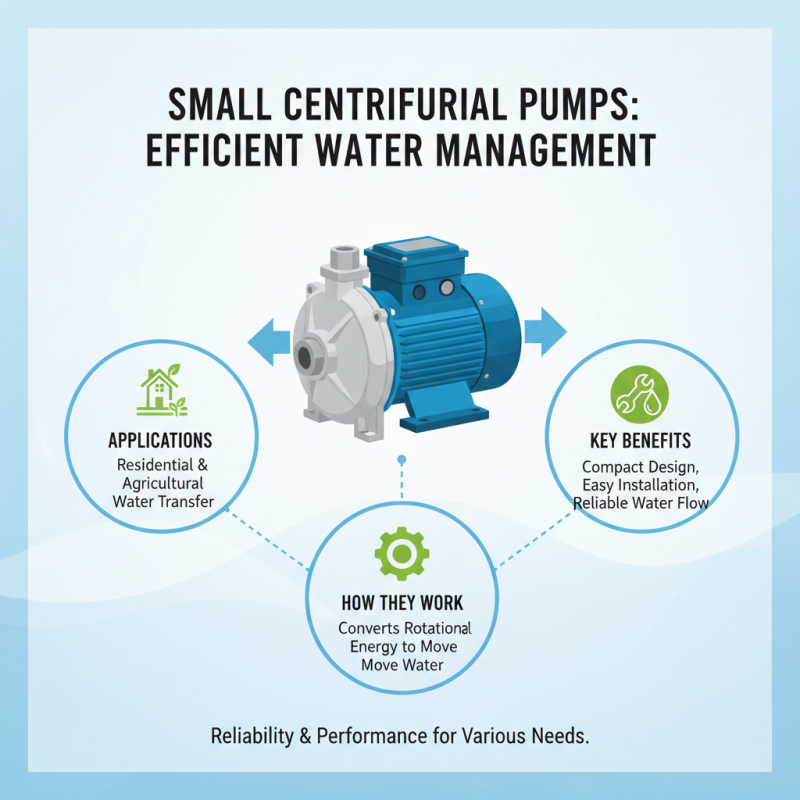

Small centrifugal pumps play a vital role in efficient water management across various applications, from agricultural irrigation to residential water supply. These pumps are designed to move water through rotational energy, utilizing a rotating impeller to create a flow. Their simplicity, reliability, and ability to handle low-viscosity fluids make them an ideal choice for numerous water management tasks. In 2023, the focus on environmentally friendly and energy-efficient technologies has further driven the development of innovative small centrifugal pump solutions that enhance performance while minimizing energy consumption.

When selecting a small centrifugal pump for water management, consider the pump's flow rate and head requirements to ensure optimal performance for your specific needs. Additionally, look for energy-efficient models that reduce operational costs and environmental impact. Regular maintenance is essential to keep your pump running smoothly; clean the impeller and check for any signs of wear and tear to prevent costly repairs in the future.

Tips: Always match the pump capacity with your system requirements to avoid overloading the pump, which can lead to inefficiency and premature failure. Remember to consider the installation environment — factors like temperature and humidity can affect pump operation and lifespan. Lastly, investing in a pump with user-friendly features will simplify operation and maintenance, ensuring your water management system runs effectively.

Key Features to Consider in Small Centrifugal Pumps

When selecting small centrifugal pumps for effective water management, several key features should be prioritized.

Firstly, pump efficiency is paramount, as it directly impacts energy consumption.

According to a recent industry report by the Hydraulic Institute, pumps can account for over 20% of a facility's energy usage;

thus, choosing a pump with a high-efficiency rating can lead to significant cost savings.

Look for models that boast an efficiency of 70% or higher,

as they not only save energy but also reduce operational costs over time.

Another essential feature to consider is the pump's capacity and flow rate. The right pump should meet the specific demands of your system without being oversized, which can lead to unnecessary energy use and wear.

The American Society of Mechanical Engineers (ASME) recommends evaluating the required flow rates during peak conditions to ensure the selected pump can handle the system's demands effectively.

Additionally, assess the material construction of the pump, as this affects the pump's durability and resistance to corrosion, especially in chemically challenging environments.

Tips:

Always consult with a professional to determine the best specifications for your application.

Moreover, it's beneficial to choose models that offer easy maintenance access,

as regular upkeep is essential for prolonged efficiency.

Investing in a pump with advanced technology features, such as variable speed control, can also enhance performance,

adjusting water flow based on real-time needs and further optimizing energy usage.

Top 10 Small Centrifugal Pumps for Efficient Water Management

When it comes to efficient water management, small centrifugal pumps are indispensable tools that provide reliability and performance. These pumps are designed to move water through a system by converting rotational energy, making them suitable for various applications, from residential to agricultural settings. Their compact design not only allows for easy installation but also enhances operational efficiency, ensuring optimal water flow for different needs.

Tips for selecting the right small centrifugal pump include considering the specific flow rate and pressure requirements of your system. It's essential to analyze the total dynamic head (TDH) to ensure the pump can deliver water effectively to its intended location. Additionally, pay attention to the pump materials, as corrosion-resistant options can significantly extend the lifespan in harsh environments. Regular maintenance is also critical; inspecting seals and bearings can prevent potential issues before they escalate.

Another important consideration is the energy efficiency of the pump. Choosing a model with a higher efficiency rating can lead to significant cost savings over time, particularly in systems that run continuously. To maximize the pump's performance, ensure that it is properly sized for your application. Oversizing can lead to inefficiencies and increased wear, while undersizing can result in inadequate water supply. Proper installation and routine check-ups will keep your pumping system reliable and effective for your water management needs.

Comparative Analysis of Performance and Efficiency

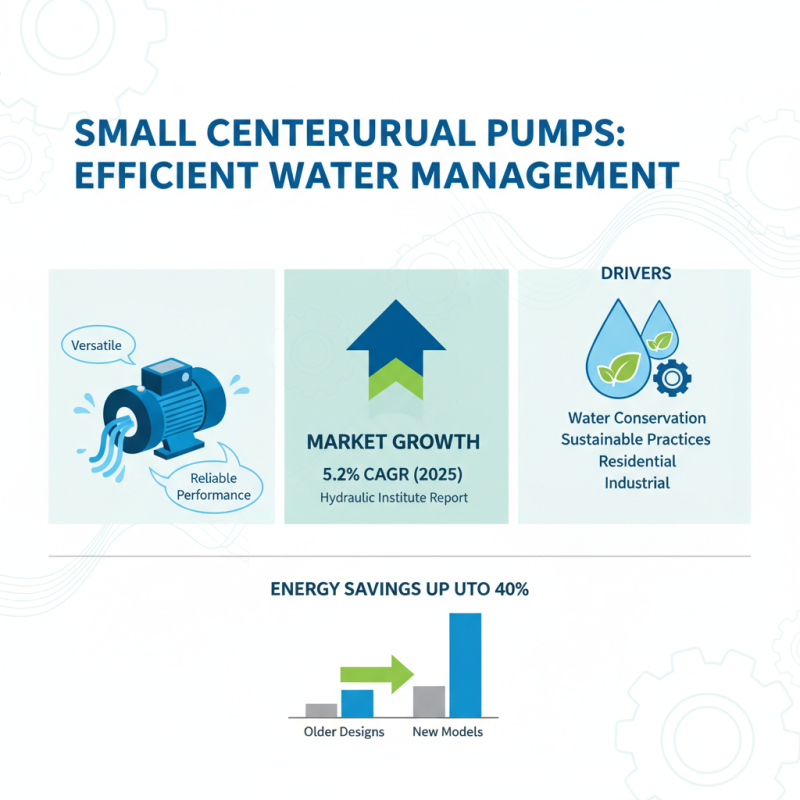

In the realm of efficient water management, small centrifugal pumps are gaining prominence due to their versatility and reliable performance. A recent report by the Hydraulic Institute indicates that the market for small centrifugal pumps is projected to grow at a CAGR of 5.2% through 2025. This growth is largely driven by the increasing demand for water conservation and sustainable practices in both residential and industrial sectors. Comparative analyses of these pumps reveal that the most efficient models can achieve energy savings of up to 40% compared to older, less efficient designs.

The performance metrics of small centrifugal pumps are crucial for optimizing water management systems. Factors such as flow rate, head pressure, and energy consumption play pivotal roles in determining the most suitable pump for specific applications. According to a study by the American Society of Mechanical Engineers (ASME), pumps that operate at or near their Best Efficiency Point (BEP) not only provide optimal flow rates but also reduce wear and maintenance costs, extending the lifespan of the equipment. Furthermore, implementing variable speed drives can enhance pump efficiency by adjusting the flow to meet demand, thereby minimizing energy waste.

Applications of Small Centrifugal Pumps in Various Industries

Small centrifugal pumps are pivotal in a variety of industries where efficient water management is crucial. In agriculture, for example, these pumps are frequently used for irrigation systems, helping to distribute water evenly across large tracts of farmland. According to the American Society of Agricultural and Biological Engineers, properly designed irrigation systems can enhance crop yield by over over 30%, underscoring the importance of effective pumping solutions in optimizing water resource management. The ability to deliver high flow rates with relatively low energy consumption makes small centrifugal pumps an attractive option for agribusinesses looking to maximize production while minimizing operational costs.

In the manufacturing sector, small centrifugal pumps play a key role in processes such as cooling, heating, and wastewater management. The global market for industrial pumps is expected to grow significantly, reaching approximately $77 billion by 2025, as reported by Markets and Markets. This growth is driven by rising demand for water treatment solutions across various manufacturing processes. Moreover, the versatility of small centrifugal pumps allows them to be used efficiently in HVAC applications, where they facilitate the circulation of water and enhance energy efficiency. By effectively managing water resources, these pumps contribute not only to operational efficiency but also to sustainability initiatives within industries.

Related Posts

-

Understanding the Mechanisms and Applications of High Head Pumps in Modern Industry

-

Maximizing Efficiency: The Role of Boiler Condensate Pumps in Energy Savings and System Performance

-

Why Canned Pumps Are Essential for Efficient Fluid Transfer in Industries

-

Maximizing Efficiency: The Ultimate Guide to Choosing the Right Vertical Centrifugal Pump for Your Needs

-

The Essential Guide to Choosing the Right Boiler Condensate Pump for Your Home

-

Maximizing Efficiency: The Essential Guide to Choosing the Right Liquid Propane Pump for Your Needs