Contact Us

Top 10 Steam Condensate Pumps for Efficient Energy Management?

In the world of industrial energy management, steam condensate pumps play a crucial role. John W. Smith, an expert in energy efficiency, once said, "The right steam condensate pump can transform energy costs significantly." Each pump is designed to recycle steam and conserve energy, which is vital in today's economy.

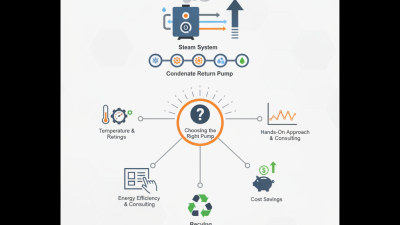

Finding the best steam condensate pump can be overwhelming. Many factors come into play, such as efficiency, size, and cost. Often, companies overlook specific needs. For instance, the right selection can reduce water treatment costs. However, not every pump is suitable for all applications. It's crucial to assess what fits best for your system.

A good steam condensate pump not only improves energy use but also enhances overall operational efficiency. Yet, choosing incorrectly can lead to increased maintenance costs. Reflecting on these points can help industry professionals make informed decisions. After all, the goal is to maximize efficiency and minimize waste.

Overview of Steam Condensate Pumps and Their Importance

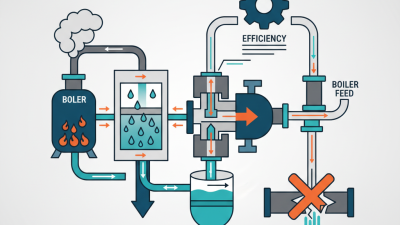

Steam condensate pumps play a vital role in energy management for industries. They efficiently remove condensate from steam systems, preventing water accumulation. By doing so, they maintain optimal steam pressures and improve system efficiency. The effectiveness of these pumps directly impacts energy consumption and operational costs.

In many cases, condensate isn't adequately managed. This can lead to issues like water hammering or corrosion. Regular maintenance is crucial to ensure pumps operate efficiently. Even minor failures can result in significant energy waste. Industries must recognize their importance for sustainability and cost-effectiveness.

Choosing the right pump can be challenging. Consider factors like capacity, temperature, and pressure ratings. Many systems face the same recurring problems. An effective solution requires assessing both existing equipment and future needs. Addressing these factors can lead to better energy management and reduced environmental impact.

Top 10 Steam Condensate Pumps for Efficient Energy Management

Key Features to Consider When Selecting Steam Condensate Pumps

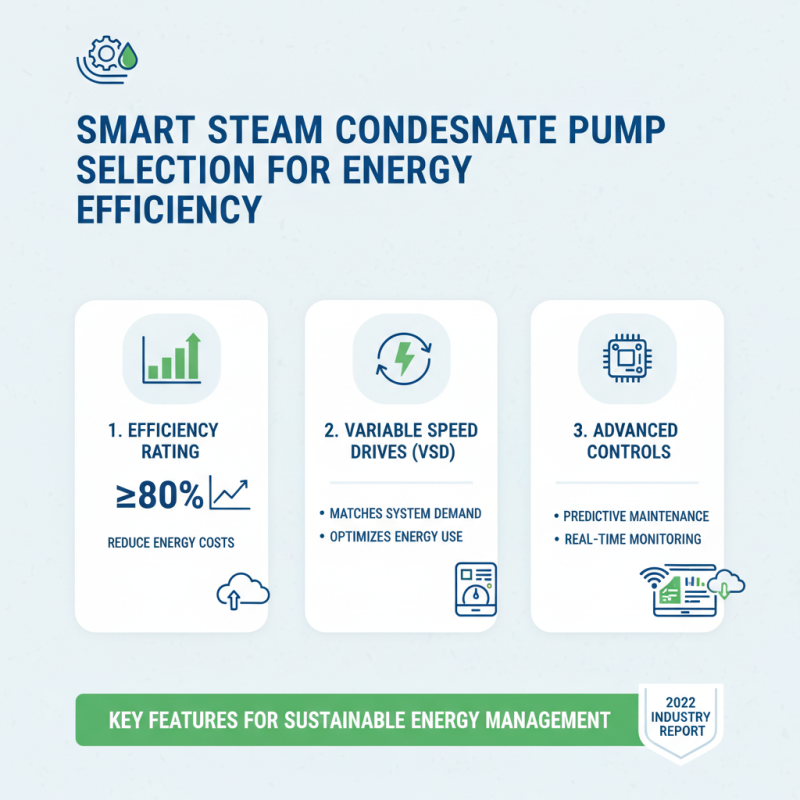

When selecting steam condensate pumps, key features play a crucial role in efficient energy management. Efficiency is paramount. According to a 2022 industry report, pumps that operate at 80% efficiency or higher can significantly reduce energy costs. Look for pumps equipped with advanced variable speed drives. These drives adjust the pump's operation to match the system's demand, optimizing energy use.

Durability is another critical factor. Pumps should be constructed from high-quality materials. Stainless steel or cast iron options resist corrosion and extend longevity. A study showed that well-maintained pumps can operate effectively for over 15 years. However, poor maintenance practices can lead to premature failure, resulting in increased operational costs.

Lastly, consider the pump's capacity and design. A properly sized pump prevents energy waste. Oversized pumps can consume more energy than necessary. Regular assessment of pump performance is essential. Many facilities overlook this, leading to ineffectiveness in energy management. By focusing on these features, facilities can enhance their overall efficiency.

Top 10 Steam Condensate Pumps for Optimal Performance and Efficiency

Efficient steam management is essential in any industrial setting. Condensate pumps play a crucial role in this process. They help return condensate to the boiler, maximizing energy utilization. However, selecting the right pump can be challenging. It's important to consider factors like capacity and head.

When choosing condensate pumps, performance is key. A pump with high efficiency can reduce energy costs. Look for models that maintain a consistent flow rate. This ensures that steam systems operate smoothly. Inefficient pumps can lead to energy waste, affecting overall productivity.

Many users overlook maintenance needs, which is critical. Regular checks can prevent unexpected breakdowns. It’s wise to have a maintenance schedule in place. Observing potential issues early can avoid costly repairs. Not every pump model will meet all requirements. Understanding specific system needs is necessary for optimal performance.

Comparison of Energy Efficiency Among the Leading Condensate Pumps

When evaluating energy efficiency in steam condensate pumps, several factors come into play. The performance of condensate pumps can vary widely based on design and operational features. Energy consumption is a key indicator. Efficient models minimize energy loss during operation, leading to savings over time. It's essential to consider factors like flow rate and pressure capabilities.

Some pumps might feature advanced technology that enhances efficiency. However, this is not always the case. Simple designs can also provide excellent performance. It's crucial to assess the specific needs of the system. A high-efficiency pump in one scenario may underperform in another. Furthermore, maintenance plays a critical role. A neglected pump can waste energy, regardless of its design.

Pump selection shouldn’t be underestimated. Overlooking compatibility with existing systems can lead to inefficiencies. Each pump has its peculiarities. Small adjustments can have big impacts. In energy management, details matter greatly. A careful comparison of options is necessary to achieve optimal energy efficiency.

Top 10 Steam Condensate Pumps for Efficient Energy Management

| Model | Flow Rate (GPM) | Pressure (psi) | Efficiency (%) | Power Consumption (kW) |

|---|---|---|---|---|

| Model A | 50 | 100 | 90 | 15 |

| Model B | 60 | 120 | 92 | 14 |

| Model C | 45 | 90 | 85 | 16 |

| Model D | 70 | 130 | 95 | 12 |

| Model E | 55 | 110 | 88 | 13 |

Maintenance Tips for Enhancing the Lifespan of Condensate Pumps

Maintaining condensate pumps is crucial for achieving efficient energy management. Regular servicing can prevent breakdowns. Pay close attention to the pump's operation. Listening for unusual noises can be an early warning sign. Check for leaks regularly, as even small leaks can lead to significant energy loss.

Consider implementing a routine maintenance schedule. This can include checking the bearings, seals, and filters. Cleaning the strainer is essential. A clogged strainer can hinder performance. Replace worn parts promptly to avoid larger issues. Remember, neglecting small repairs often leads to costly problems later.

Monitoring the temperature and pressure levels is vital. High levels can indicate inefficiencies. Adjusting these levels promptly can save energy. Use vibration analysis to detect mechanical issues early. Regular checks can extend the lifespan of your pump. Energize your maintenance routine and witness the benefits.

Related Posts

-

Top 10 Steam Condensate Return Pumps to Optimize Your System in 2025

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Why is a Steam Condensate Return Pump Essential for Energy Efficiency?

-

How to Choose the Right Steam Condensate Return Pump for Your System?

-

What is a Steam Condensate Pump and How Does It Work?

-

2026 How to Choose the Right Commercial Condensate Pump for Your Needs?