Contact Us

Top 10 Turbine Pump Types for Efficient Water Management Systems

The efficient management of water resources is critical in various sectors, from agriculture to municipal water supply systems. One of the most effective solutions for achieving optimal water flow and distribution is through the use of turbine pumps. These powerful devices are designed to transport water efficiently and can handle a wide range of applications, making them indispensable in modern water management systems. This article will explore the top 10 turbine pump types, examining their unique characteristics, benefits, and suitability for different operational requirements.

As the demand for sustainable water management solutions continues to grow, understanding the functionality and advantages of different turbine pump designs becomes essential. By delving into the distinctive features of each type, we can help you choose the right turbine pump that aligns with your specific needs. As we explore these types, we will highlight the engineering innovations that enhance their performance and discuss how they contribute to the overall efficiency and reliability of water management systems.

Overview of Turbine Pumps in Water Management Systems

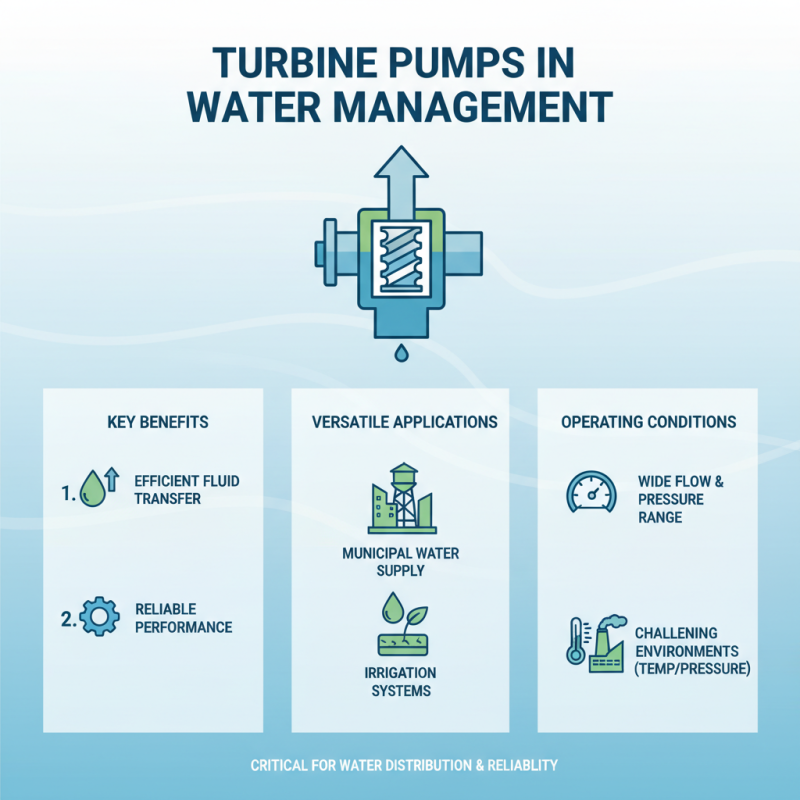

Turbine pumps play a vital role in water management systems by providing efficient fluid transfer and distribution across various applications. These pumps are designed to handle a wide range of flow rates and pressures, making them suitable for municipal water supply, irrigation systems, and industrial water applications. Their ability to operate in challenging environments, including adverse temperature and pressure conditions, adds to their versatility, ensuring reliable performance over an extended period.

The design of turbine pumps enables them to draw water from deep wells or reservoirs, making them particularly effective in areas where water sources are located underground. The multistage design allows for significant lift capabilities and helps maintain a consistent flow rate, which is crucial for efficient water management. Additionally, turbine pumps can be easily integrated with monitoring and control systems, facilitating real-time management and adjustments based on demand. As water management becomes increasingly critical in addressing global challenges such as climate change and population growth, the role of turbine pumps in ensuring sustainable and efficient water distribution continues to grow.

Types of Turbine Pumps and Their Applications

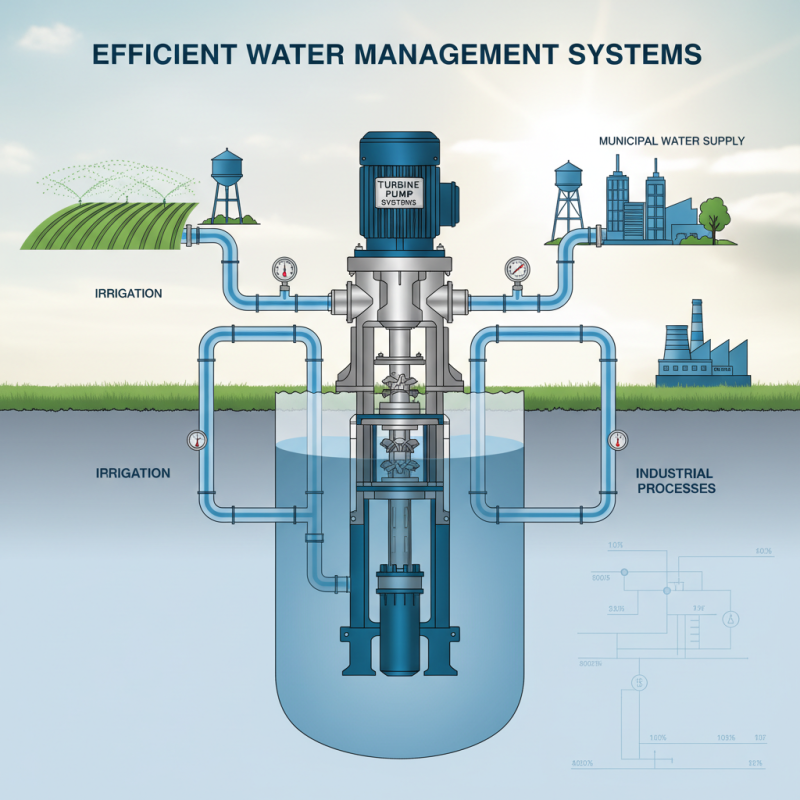

Turbine pumps are essential tools in water management systems, widely recognized for their efficiency in various applications including agriculture, municipal water supply, and industrial processes. These pumps operate on the principle of converting rotational energy into hydraulic energy, making them ideal for lifting water from deep wells and transporting it over long distances. According to recent industry reports, turbine pumps can achieve efficiency levels exceeding 90%, proving to be reliable in high-demand scenarios.

Among the different types of turbine pumps, vertical turbine pumps are popular for their compact design and high efficiency in deep well applications. Horizontal turbine pumps, on the other hand, are preferred for surface water applications where space and mobility are considerations. Additionally, mixed flow turbine pumps serve a dual purpose, functioning effectively in both vertical and horizontal installations, which enhances their versatility across different projects.

Tips: When selecting a turbine pump, consider the specific application and the required flow rate and head. It is crucial to choose a pump that not only meets these parameters but also aligns with energy efficiency goals, as energy consumption could represent a significant operational cost. Regular maintenance and monitoring can further enhance the longevity and performance of these pumps, ensuring optimal water management practices.

Top 10 Turbine Pump Types for Efficient Water Management Systems

This chart illustrates the top 10 turbine pump types commonly used in water management systems, showcasing their efficiency ratings and common applications.

Advantages of Using Turbine Pumps for Water Efficiency

Turbine pumps play a pivotal role in enhancing water efficiency across various applications, making them a popular choice for water management systems. One of the key advantages of turbine pumps is their ability to operate efficiently at varying flow rates while maintaining consistent pressure. This adaptability allows for optimized energy consumption, significantly reducing operational costs over time. Additionally, their vertical design minimizes the footprint needed for installation, making them suitable for space-constrained applications.

Another benefit of turbine pumps is their capability to handle large volumes of water with high head requirements. This characteristic makes them particularly effective for deep well applications or situations where water needs to be lifted over considerable heights. Their robust construction and reliable performance also contribute to reduced maintenance needs, further enhancing overall water efficiency. By utilizing turbine pumps, water management systems can achieve an eco-friendly approach, ensuring sustainability while meeting demand effectively.

Top 10 Turbine Pump Types for Efficient Water Management Systems

| Pump Type | Application | Flow Rate (GPM) | Head (ft) | Efficiency (%) | Advantages |

|---|---|---|---|---|---|

| Vertical Turbine Pump | Irrigation | 200 | 150 | 85 | Space-saving design |

| Submersible Turbine Pump | Groundwater extraction | 300 | 200 | 90 | Higher efficiency at depth |

| Horizontal Turbine Pump | Water supply | 250 | 100 | 80 | Easy maintenance |

| Mixed Flow Turbine Pump | Industrial applications | 400 | 180 | 75 | Versatile use |

| End Suction Turbine Pump | Firefighting | 150 | 120 | 82 | Compact size |

| Canister Turbine Pump | Wastewater | 350 | 160 | 88 | Durable design |

| Deep Well Turbine Pump | Irrigation | 500 | 220 | 91 | Ideal for deep applications |

| Multi-Stage Turbine Pump | Desalination | 600 | 300 | 93 | High efficiency for long-distance |

| Self-Priming Turbine Pump | Pool filtration | 200 | 100 | 84 | User-friendly operation |

| Pressure-Boosting Turbine Pump | Municipal water supply | 330 | 250 | 87 | Enhances water pressure |

Factors Influencing the Selection of Turbine Pumps

The selection of turbine pumps for efficient water management systems is influenced by several key factors that ensure optimal performance and reliability. One of the primary considerations is the specific application for which the pump is needed, as different settings such as irrigation, municipal water supply, or industrial processes require varying pump characteristics. Understanding the fluid dynamics involved and the operating environment, including temperature and pressure conditions, plays a crucial role in determining the suitable type of turbine pump.

Another significant factor is the pump's efficiency and energy consumption. Selecting a turbine pump with a high efficiency rating can lead to substantial operational cost savings over time. Additionally, considerations regarding the total dynamic head, which includes the elevation difference and the friction losses in the system, must be accounted for to ensure that the pump can adequately meet the required flow rate. Material compatibility is also essential, especially if the pump will be handling corrosive or abrasive fluids. By carefully evaluating these factors, decision-makers can select the most appropriate turbine pump to enhance water management systems' efficiency and longevity.

Maintenance Practices for Optimal Turbine Pump Performance

Efficient maintenance of turbine pumps is crucial for ensuring optimal performance in water management systems. Regularly scheduled maintenance not only extends the lifespan of the pumps but also prevents unexpected failures that can lead to costly downtime. According to a report by the American Society of Mechanical Engineers, well-maintained turbines can improve operational efficiency by up to 15%. Key practices include routine inspections, lubrication of moving parts, and monitoring of vibration levels to detect potential issues early on.

To optimize turbine pump performance, operators should adopt a proactive maintenance approach. Regularly checking alignment and ensuring proper sealing can prevent leaks and minimize energy loss. Furthermore, implementing predictive maintenance techniques, such as using vibration analysis and thermography, allows for timely interventions. A study published in the Journal of Water Resources Planning and Management highlighted that predictive maintenance reduces the overall operational costs by up to 20% compared to reactive maintenance strategies.

Tips: Always maintain a detailed log of maintenance activities and pump performance metrics. This documentation not only helps in identifying patterns but also aids in making informed decisions for future maintenance needs. Additionally, training staff on best practices for turbine pump operation can significantly enhance the effectiveness of maintenance efforts.

Related Posts

-

Unlocking the Power: How High Pressure Pumps for Water Revolutionize Industrial Applications

-

7 Essential Tips for Choosing the Right Boiler Condensate Pump for Your Home

-

Why a High Temp Condensate Pump is Essential for Efficient Steam Systems

-

Top 10 Condensate Pumps for Efficient HVAC Systems in 2023

-

2025 Guide: How to Choose the Right Vertical Turbine Pump for Your Needs

-

The Future of Industrial Centrifugal Pumps Innovations and Trends You Need to Know